Bioerodible magnesium alloy microstructures for endoprostheses

A bio-erosion, magnesium alloy technology, applied in prosthesis, surgery, medical science, etc., to achieve the effect of improving ductility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

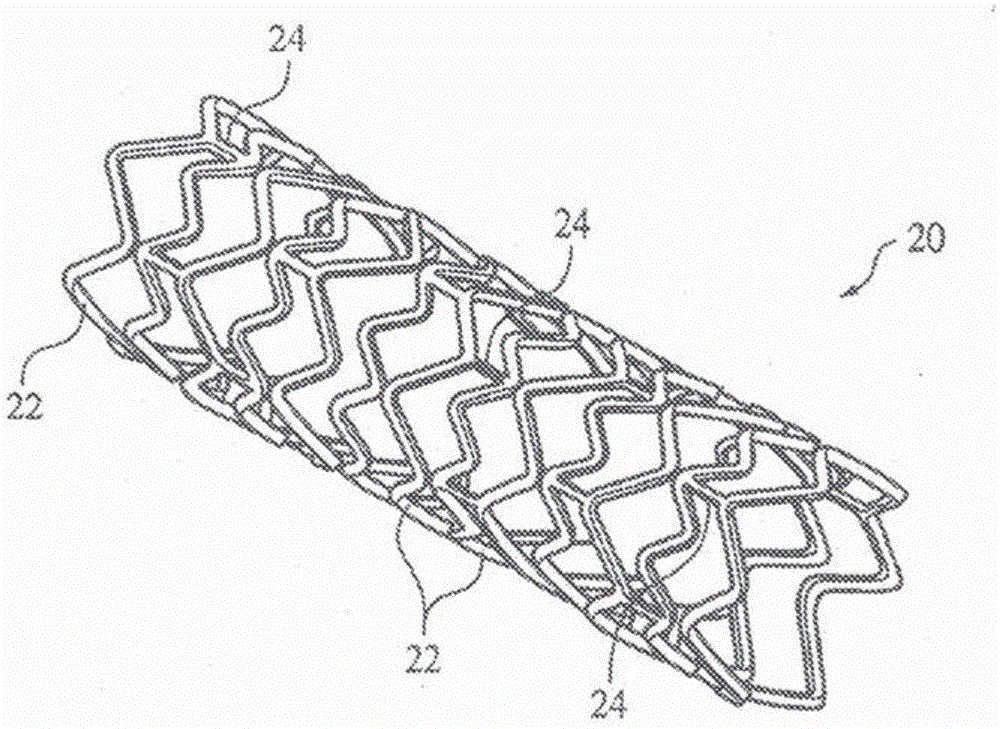

[0016] figure 1 The stent 20 shown in is an example of an endoprosthesis. The stent 20 comprises a pattern of interconnected struts that form a structure that contacts the walls of the body lumen to maintain the patency of the body lumen. For example, stent 20 may have a tubular member defined by a plurality of cuffs 22 and a plurality of joints 24 extending and connecting adjacent cuffs. During use, the cuff 22 can expand from an initial small diameter to a larger diameter to contact the stent 20 against the vessel wall, thereby maintaining the patency of the vessel. Joints 24 provide stent 20 with flexibility and compliance that allow the stent to conform to the contours of the vessel. Other examples of endoprostheses include stent-grafts and stent-grafts.

[0017] At least one strut of stent 20 is adaptable to erosion under physiological conditions. In some cases, scaffold 20 is fully bioerodible. Stent 20 may comprise a bioerodible magnesium-aluminum alloy having a re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| ultimate tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com