A fully automatic key blank stamping machine

A fully automatic, punching machine technology, applied in the direction of feeding device, positioning device, storage device, etc., can solve the problems of easy waste of plate raw materials, harm to human health, low processing efficiency, etc., to achieve high processing efficiency and reduce physical health. damage, smooth processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

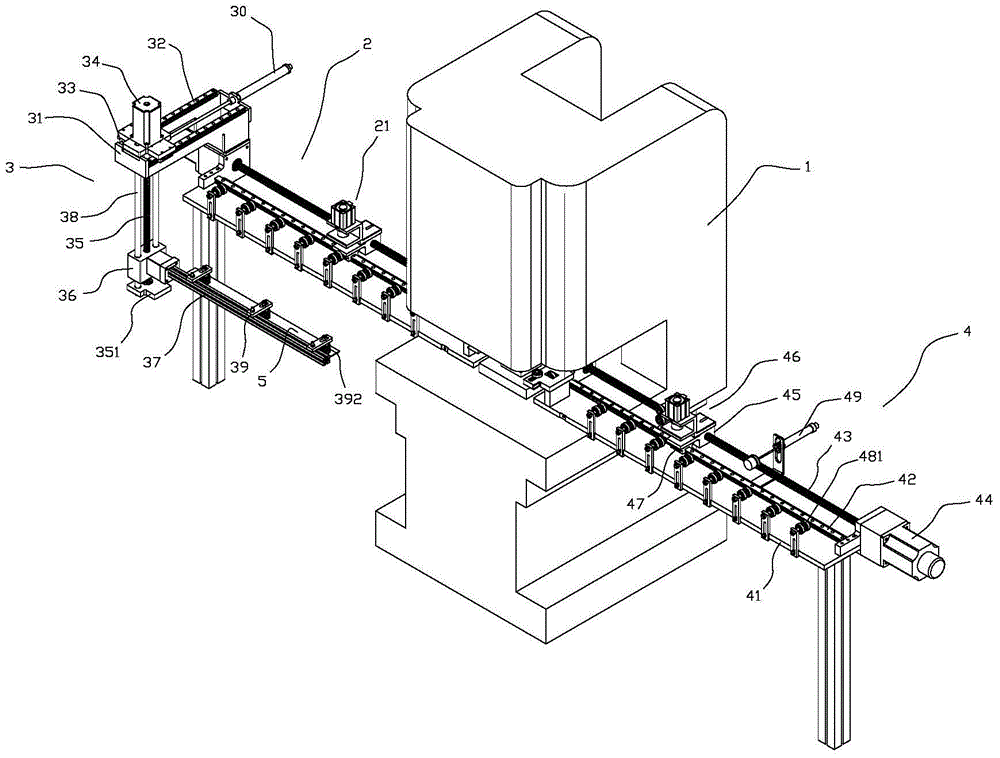

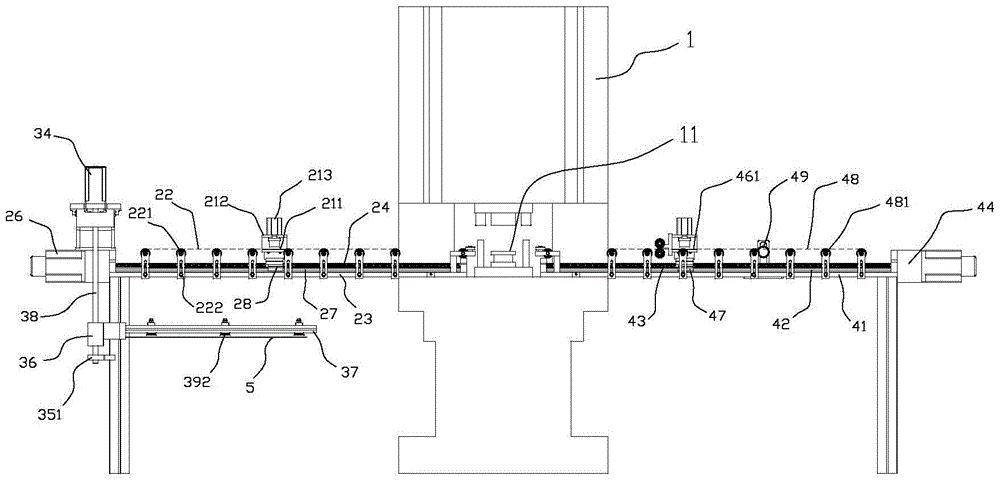

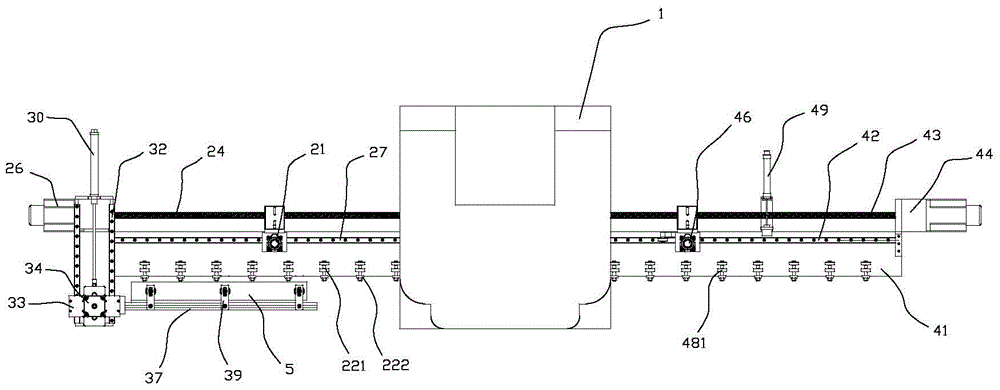

[0024] Example 1: see figure 1 , figure 2 , image 3 , a fully automatic key blank stamping machine, comprising a stamping device 1 with a stamping platform 11, the front end of the stamping platform 11 is provided with a feeding device 2 that can transport the plate 5 to the stamping device 1 in a horizontal and straight line for stamping, the feeding device 2. It includes a material clamping mechanism 21 that can clamp and fix the plate 5 and at the same time drive the plate to move linearly in the direction of the stamping platform 11. The material clamping mechanism 21 is provided with a material clamping plane 211 that is in contact with the lower surface of the plate. 211 and stamping platform 11 become equal height setting. Wherein, the material clamping mechanism 21 includes a material clamping cylinder support 212, the material clamping plane 211 is arranged on the material clamping cylinder support 212, and the material clamping cylinder support 212 is provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com