High-precision clamp for quickly replacing hobbing teeth of disc gear

A gear hobbing jig, high-precision technology, applied in the field of high-precision quick-change gear hobbing jigs, gear hobbing replacement jigs, can solve the problems of affecting processing quality, poor universality of fixtures, and increased costs, so as to improve product processing Quality, improved applicability, effect of reduced clearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention is described in further detail below in conjunction with accompanying drawing:

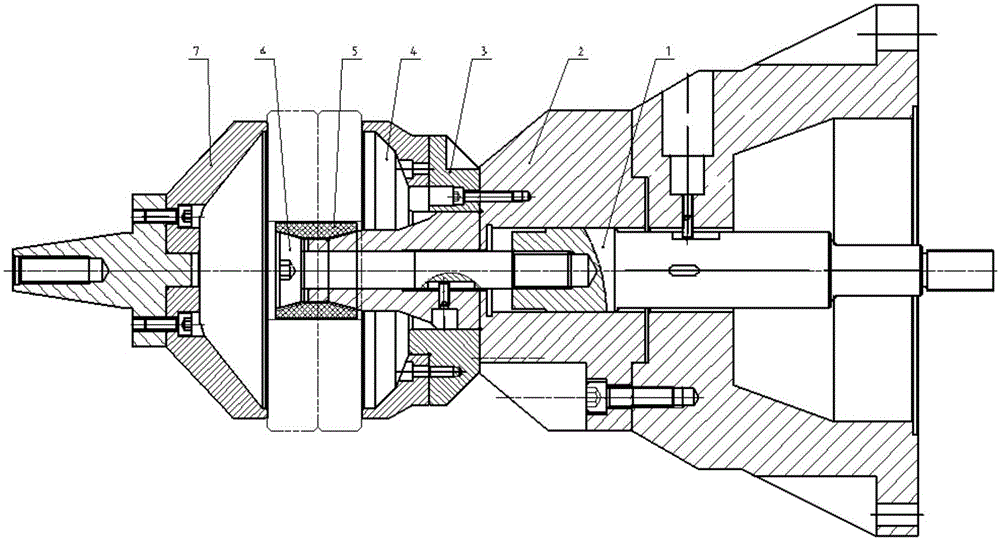

[0017] see figure 1 , the present invention comprises the mandrel 2 that is installed on the workbench of the machine tool, and the lower support 4, the double-cone adhesive expansion sleeve 5, the upper tie rod 6 and the upper gland 7 are successively installed on the mandrel 2; the upper tie rod 6 is connected with the machine tool tie rod 1 . The lower support 4 is connected with the mandrel 2 through the transition pad 3 . The transition pad 3 is fixedly connected with the mandrel 2 through bolts. The lower support 4 is fixedly connected with the transition pad 3 by bolts. The lower support 4 is a split structure for easy disassembly. The inner cone surface of the double-cone bonding expansion sleeve 5 matches the mandrel 2 .

[0018] According to the diameter of the positioning inner hole of the processed part, the present invention selects suitable mandrel s...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap