Pipeline liquid phase diffusion welding clamping centering device

A liquid phase diffusion and centering device technology, applied in auxiliary devices, welding equipment, welding equipment, etc., can solve the problems of low accuracy and low efficiency, and achieve the effect of reducing stress concentration and high centering accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

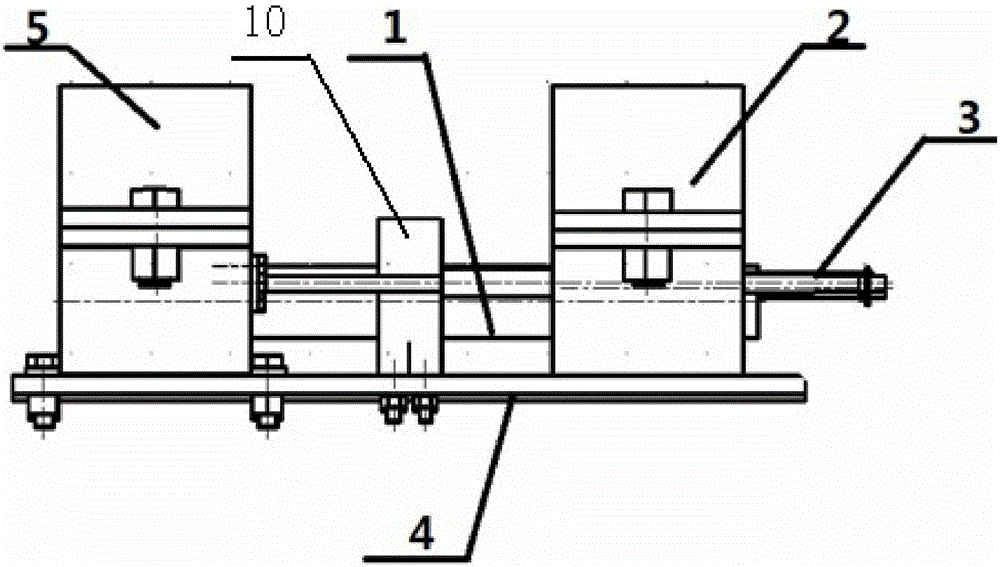

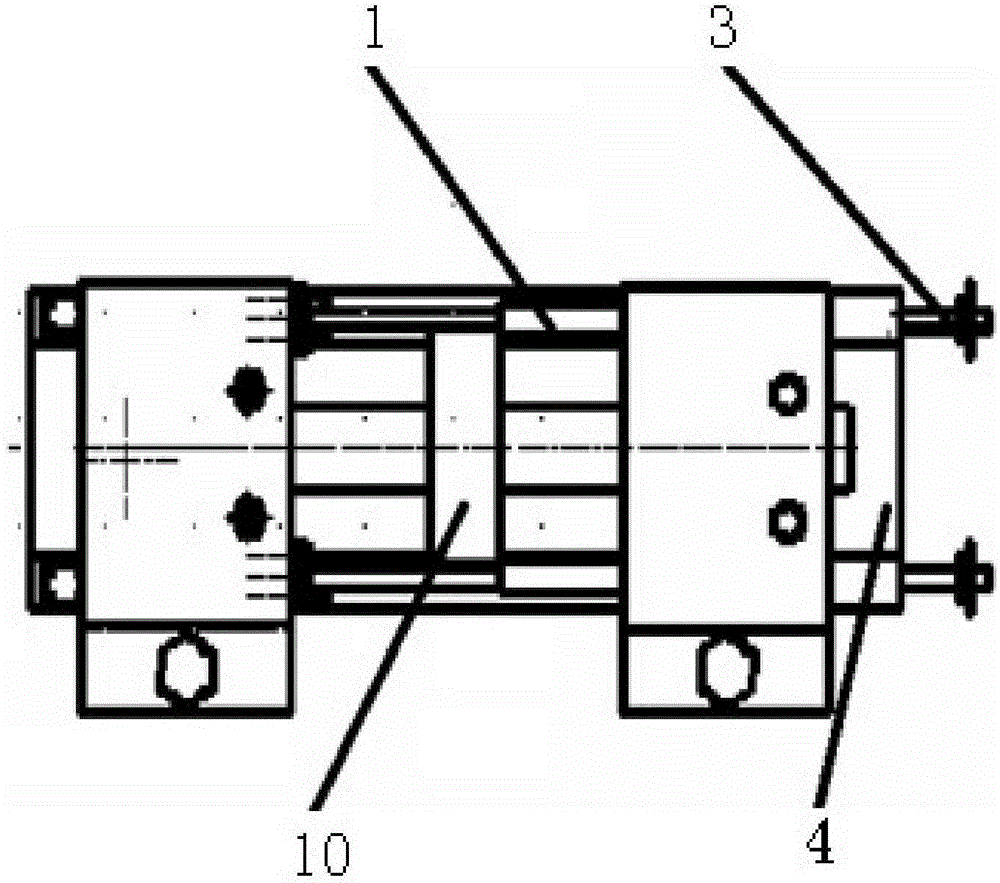

[0021] Such as figure 1 , image 3 As shown, it mainly includes: jacking mechanism 1 , sliding clamping mechanism 2 , auxiliary jacking mechanism 3 , sliding mechanism 4 , fixed clamping mechanism 5 , and welding device 10 . The clamping mechanism 1 and the sliding clamping mechanism 2 support PLC programming control.

[0022] It is light in weight and compact in overall structure. It has a centrally symmetrical structure and is controlled by a hydraulic system to ensure high-precision alignment requirements.

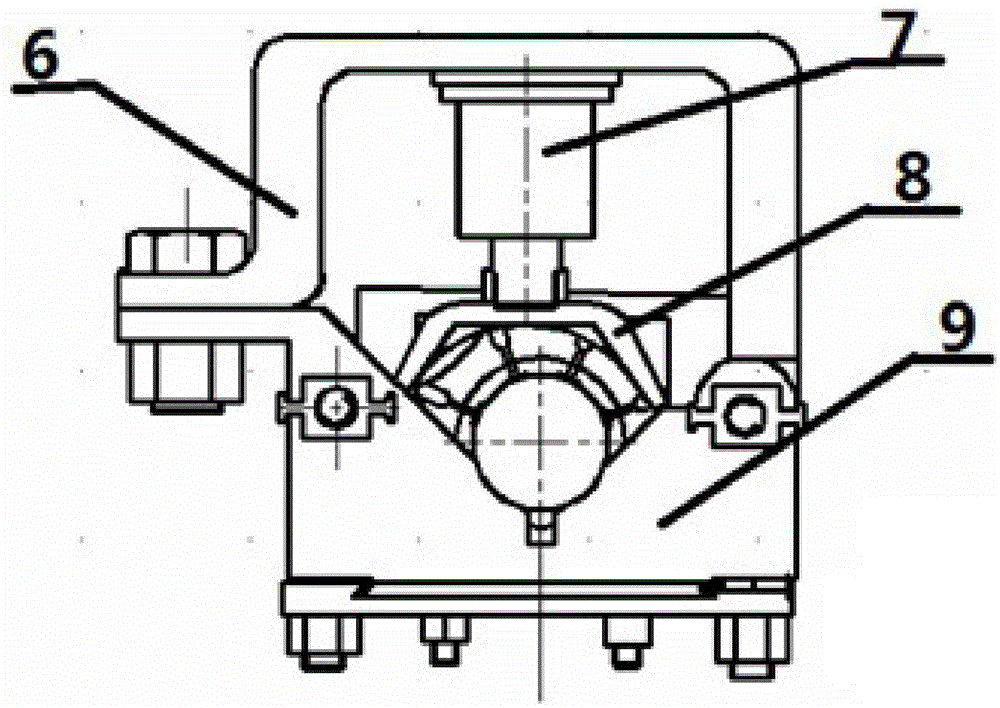

[0023] Such as figure 2 As shown, the sliding clamping mechanism 2 and the fixed clamping mechanism 5 mainly include: a semi-open valve 6 , a hydraulic cylinder 7 , clamping claws 8 , and a V-shaped bracket 9 .

[0024] Working principle: open the valve and put the pipe in, adjust the ellipticity of the pipe by external force, then slide the clamping mechanism 2 to clamp the pipe, close the valve, open the hydraulic cylinder switch, set the program pressure, and co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com