Direction recognizing device for upper end covers in automatic assembly line of filter element

An assembly line, automatic technology, applied in the direction of assembly machines, transportation and packaging, metal processing equipment, etc., can solve the problems of complex structure such as vibration material arrangement, material distribution, etc., and achieve low cost, high adjustment efficiency, and simple device structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Preferred embodiments of the present invention are described in detail as follows in conjunction with accompanying drawings:

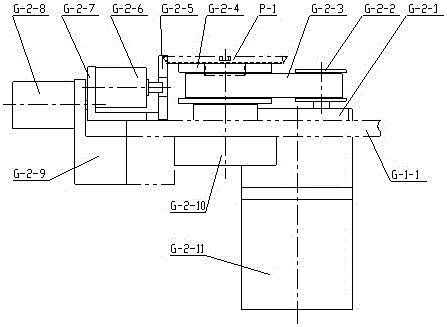

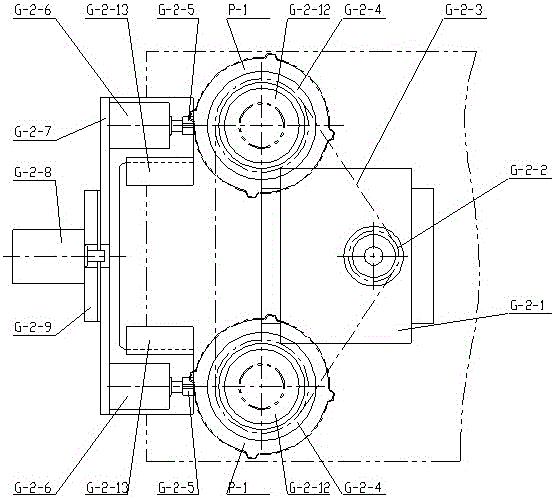

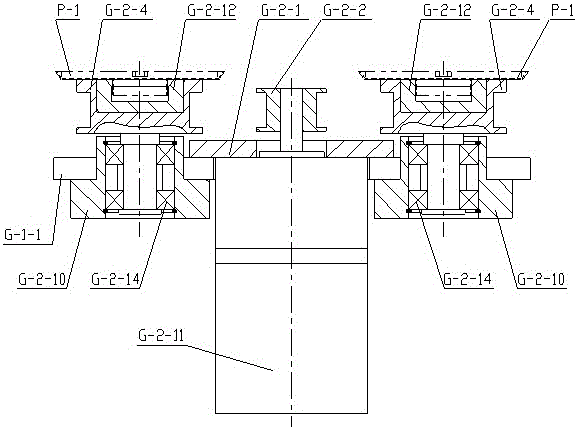

[0015] see figure 1 , figure 2 , image 3 , an upper end cap recognition device in an automatic filter element assembly line, comprising a mounting plate G-1-1 and two upper end caps P-1, characterized in that: fixedly installed in the middle above the mounting plate G-1-1 A motor mounting plate G-2-1, a motor G-2-11 is fixedly installed under the motor mounting plate G-2-1, and a driving pulley G is fixedly mounted on the output shaft of the motor G-2-11 -2-2; Two bearing seats G-2-10 are fixedly installed on the left side of the mounting plate G-1-1, and two bearings G-2-14 are fixedly installed in each bearing seat G-2-10, each A phase turntable G-2-4 is set in the inner ring of the two bearings G-2-14, and a positioning sleeve G-2-12 is placed in each phase turntable G-2-4, and the upper end cover P that needs to be recognized -1 is pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com