Automatic assembling production line for high-speed rail overhead line system droppers

An automatic assembly and catenary technology, applied in the direction of assembly machines, metal processing, metal processing equipment, etc., can solve the problems of insufficient detection, long manual assembly time, missing assembly, etc., to prevent discoloration and rust, and save labor intensity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

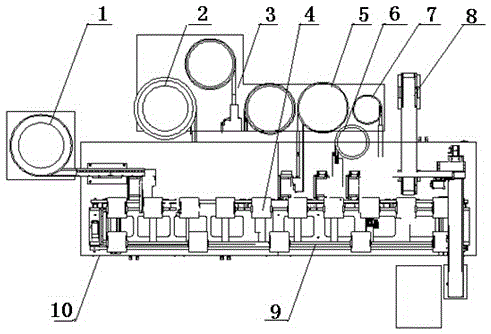

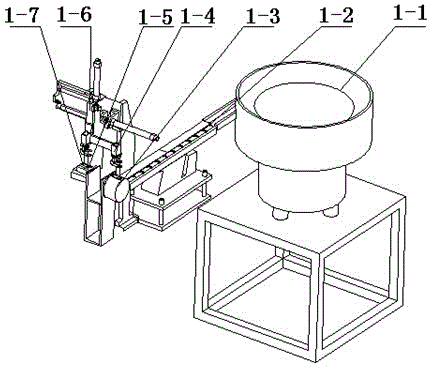

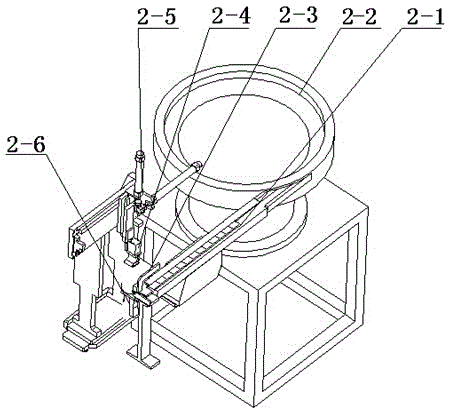

[0027] Depend on figure 1Known: An automatic assembly line for high-speed catenary suspension strings, which consists of an automatic feeding mechanism for the suspension ring 1, an automatic feeding mechanism for the wire clamp body 2, an automatic feeding mechanism for upper stop washers and hexagon head bolts 3, a semi-finished product turning mechanism 4, and a stopper Dynamic washer II automatic feeding mechanism 5, tooth surface butterfly anti-loosening washer automatic feeding mechanism 6, hex nut automatic feeding and tightening mechanism 7, unqualified finished product, qualified product unloading mechanism 8, tooling fixture circulation mechanism 9, machine The frame assembly 10 is composed of; the automatic feeding mechanism 1 of the suspension ring is composed of a suspension ring vibration plate 1-1, a linear vibrator machine material track 1-2, a position conversion mechanism 1-3, a feeding jaw 1-4, and an intermediate refueling mechanism. The warehouse 1-5, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com