Novel multi-station disc type buffing machine

A cloth wheel polishing and disc-type technology, which is applied to surface polishing machine tools, grinding/polishing equipment, manufacturing tools, etc., can solve the problems of high labor intensity, expensive equipment, and inability to polish workpieces, etc., to achieve high quality and high-efficiency polishing, reducing equipment energy consumption and production costs, improving production efficiency and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

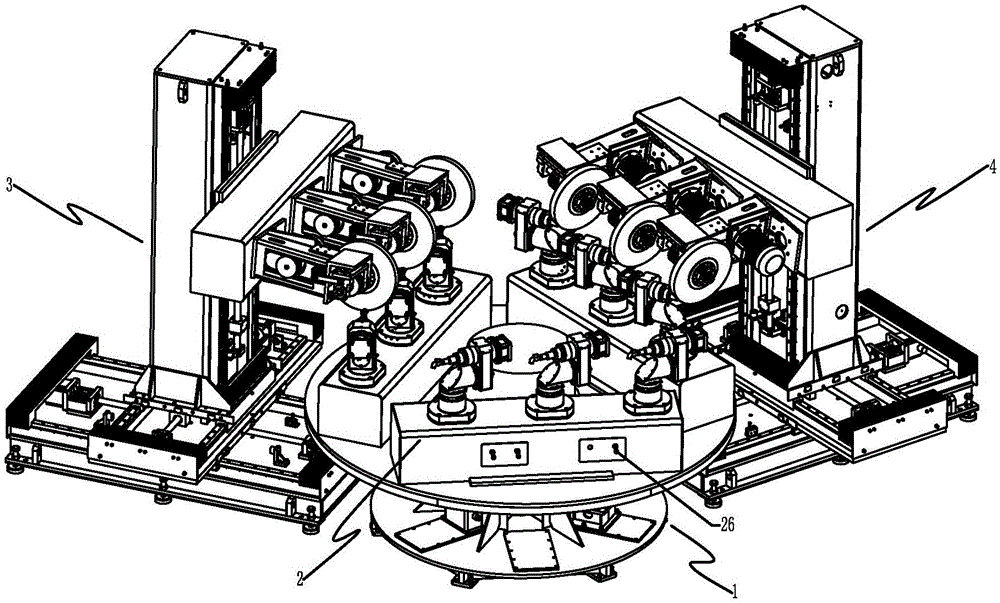

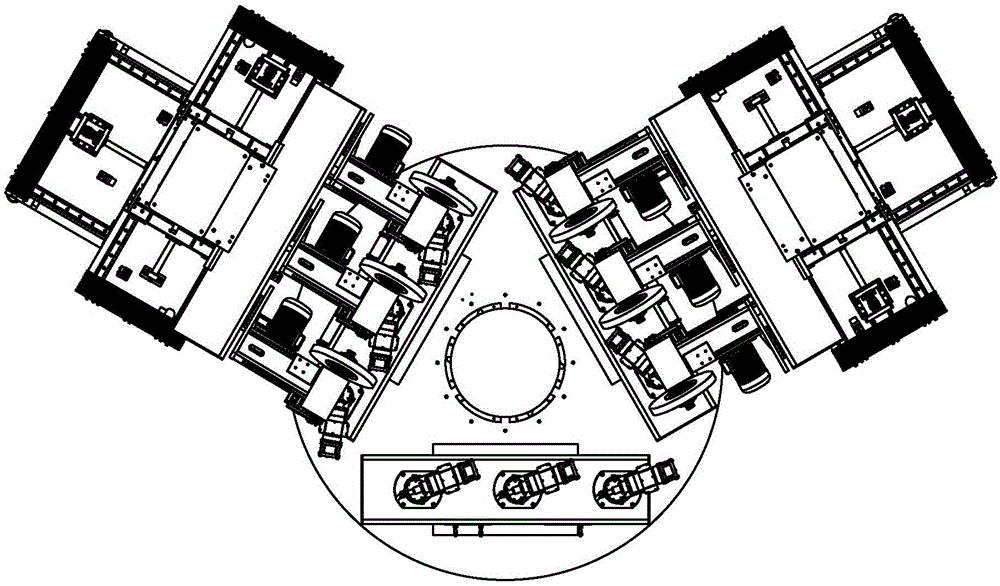

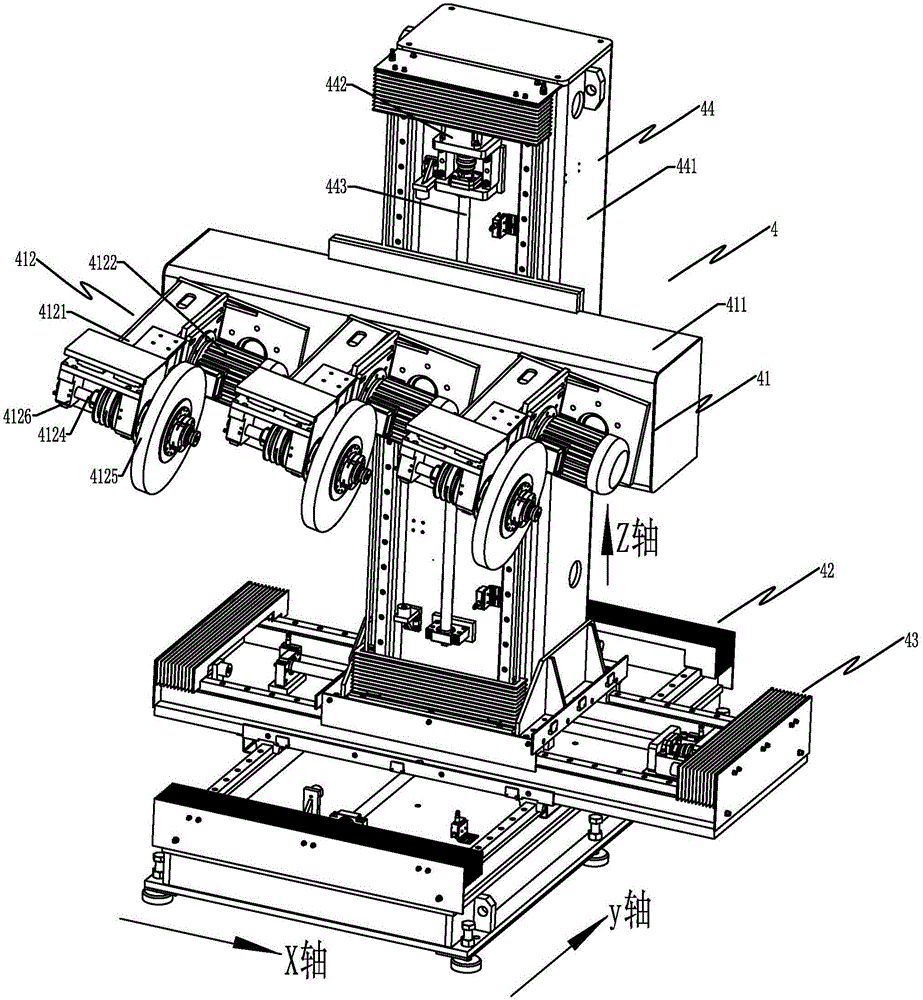

[0041] like figure 1 , 2As shown, the multi-station disc type new cloth wheel polishing machine of the present invention includes a turntable assembly 1, and the top of the turntable assembly 1 is equiangularly arranged with three clamping devices 2 along the circumferential direction. The periphery of the turntable assembly 1 corresponds to one of the clamp devices of the station to form a loading and unloading station, and each clamp device corresponding to the remaining two stations is respectively provided with a cloth wheel polishing device 3,4, and the cloth wheel polishing device 3,4 can be Respectively hemp wheel polishing wheel and / or cloth wheel polishing wheel, (hereinafter described with cloth wheel polishing device 4).

[0042] like Image 6 , 7 As shown, each of the clamp devices 2 includes a clamp support 21, three linked clamp assemblies 22 arranged on the clamp support, and a clamp drive assembly 23; wherein:

[0043] The above-mentioned fixture support 21...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com