Carpentry tooth slotting machine

A combing machine and woodworking technology, which is applied to wood processing equipment, manufacturing tools, circular saws, etc., can solve the problems of high cost, increased cost, and increased maintenance cost, and achieve high work efficiency, convenient heat dissipation, and improved safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

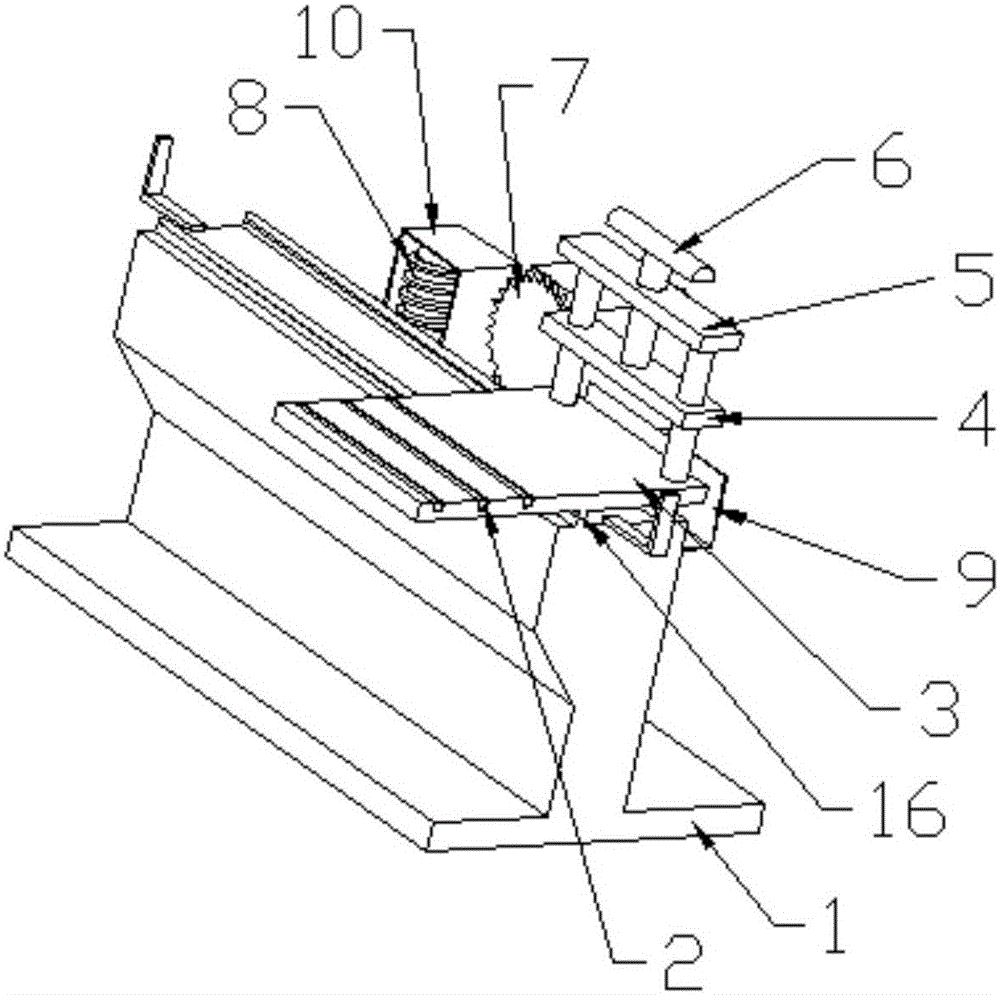

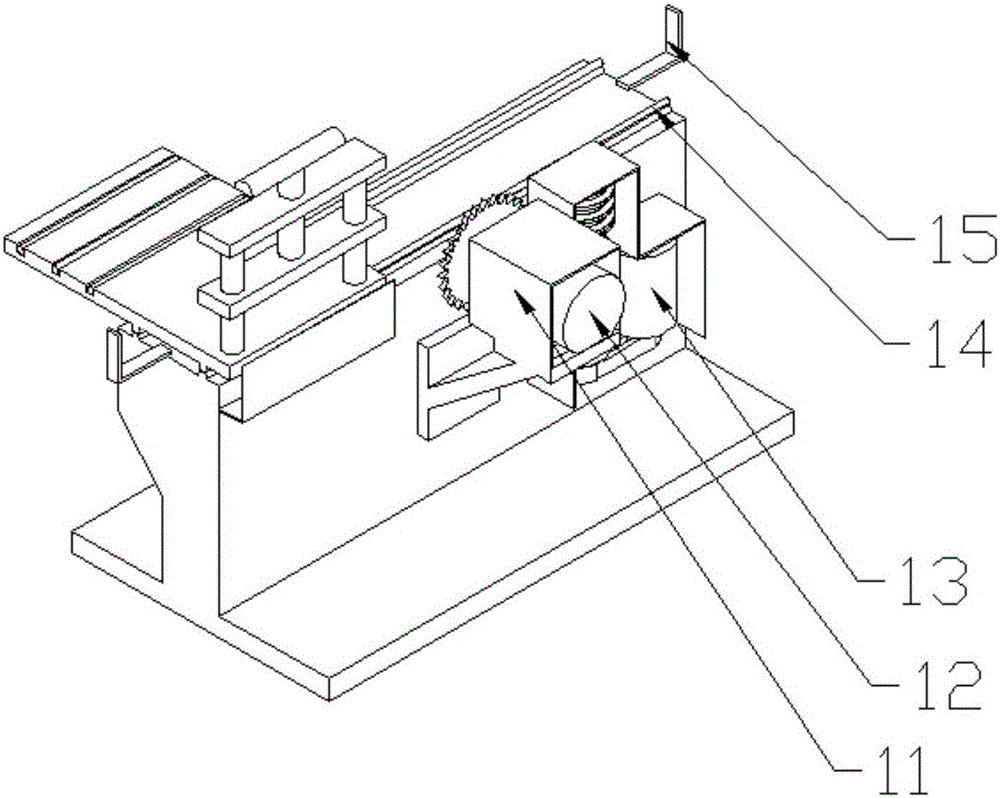

[0016] Such as figure 1 , figure 2 As shown, the present invention is a woodworking comb machine, including a base 1, an electric roller 2, a mobile table 3, a pressing plate 4, a fixed frame 5, a handle 6, a saw disc 7, a comb cutting tool 8, a baffle 9, An anti-dust safety cover 10, a motor shield 11, a first motor 12, a second motor 13, a guide rod 14, a limit plate 15 and a linear needle roller bearing 16.

[0017] A mobile platform 3 is arranged above the base 1. The mobile platform 3 is slidingly connected to the base 1. One end of the mobile platform 3 is aligned with one end of the longitudinal end face of the base 1. The mobile platform 3 can move along the longitudinal direction of the base 1. Above the mobile platform 3 An electric drum 2 is provided at one end of the base 1, and a saw disc 7 driven by a first motor 12 is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com