Rail transit magnetic track brake provided with horizontal magnet exciting coils

A technology for magnetic rail brakes and excitation coils, which is applied in the direction of brakes, railway braking systems, and railway car body parts where the braking elements interact with the rails, etc. Shell wear, low braking efficiency of the excitation coil body, etc., to achieve the effect of ensuring good contact, improving reliability, and large braking force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

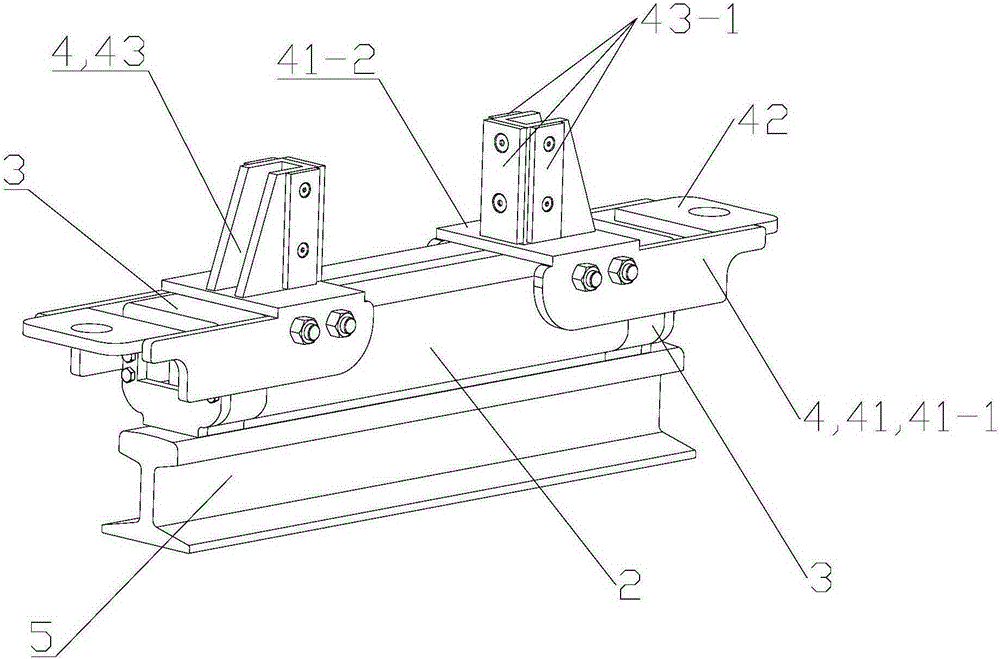

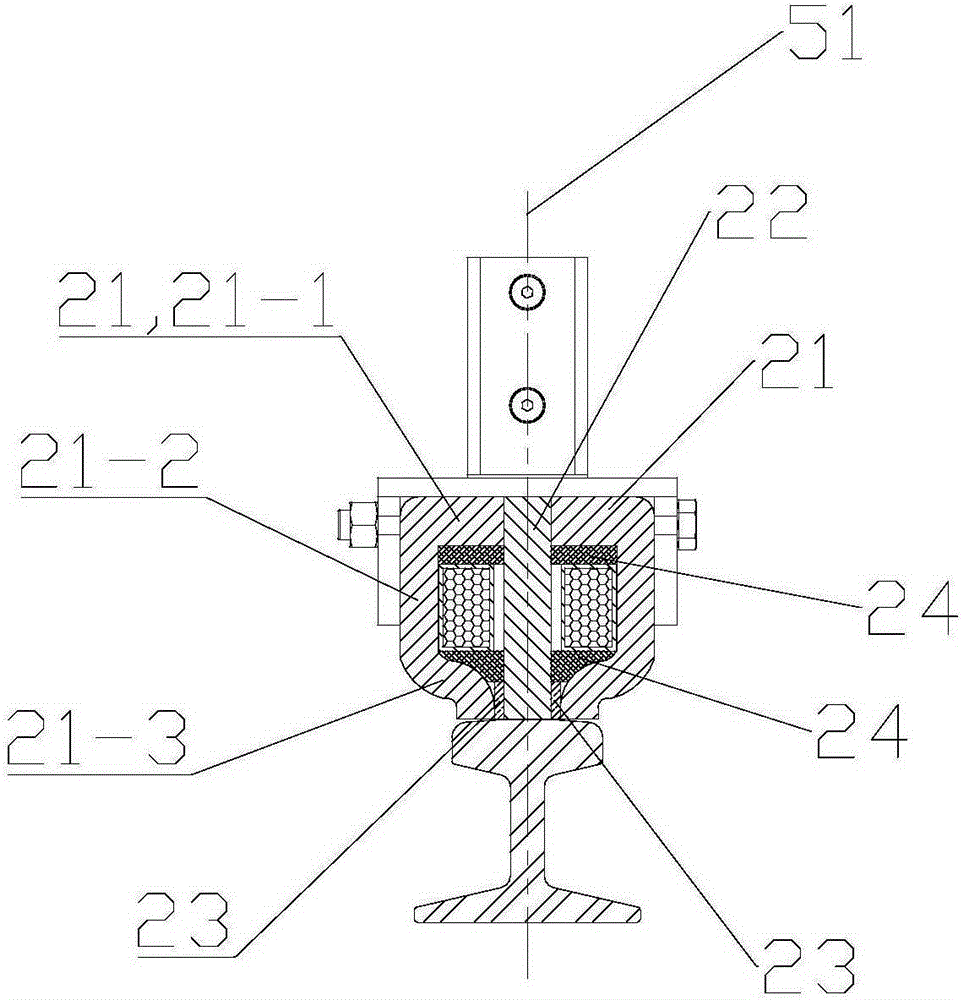

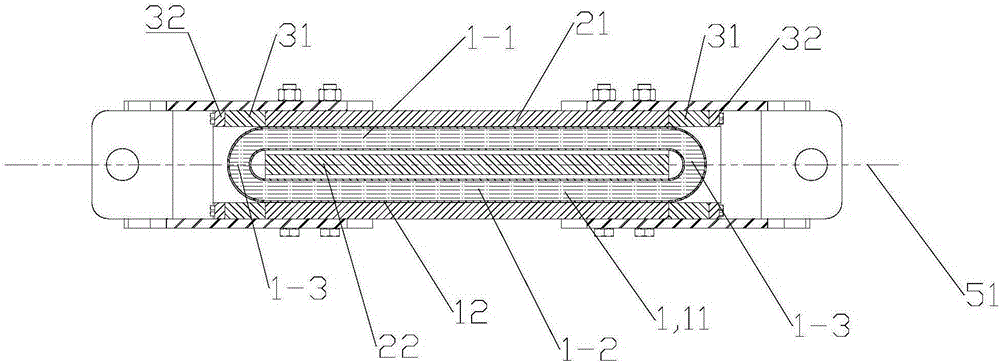

[0031] see attached figure 1 and attached image 3 The present invention discloses a rail transit magnetic track brake with a horizontally arranged excitation coil for rail transit vehicles, the magnetic rail brake includes an excitation coil assembly 1 , an iron core unit 2 , an end assembly 3 and a force transmission assembly 4 .

[0032] The excitation coil assembly 1 includes an excitation coil 11 and a coil protection case 12 , and the coil protection case 12 is wrapped around the periphery of the excitation coil 11 .

[0033] The excitation coil 11 is a group of coils composed of some winding coils. The excitation coil 11 has an elongated annular structure as a whole.

[0034] The coil protection shell 12 is a closed thin shell structure. The shape of the inner cavity of the coil protection shell 12 is completely consistent with the outer contour of the excitation coil 11. The excitation coil 11 is placed inside the coil protection shell 12 and completely wrapped by the...

Embodiment 2

[0045] The structural composition of the magnetic track brake of embodiment 2 is basically the same as that of the magnetic track brake of embodiment 1, and the distinguishing features are:

[0046] Each end assembly 3 includes an end cover 31 and a clearing board 32 , the outer contour shape of the end assembly 3 is consistent with the outer contour shape of the iron core unit 2 , and the middle part of the end assembly 3 is a hollow cavity. A gap is cut out on the lower end face of the end cover 31 to set up a clearing board 32. The clearing board 32 is made of elastic wear-resistant material and has the effect of an eraser. .

[0047] The two end assemblies 3 completely contain the circular arcs 1-3 at the front and rear ends of the excitation coil assembly 1 in the hollow cavity, and the two end assemblies 3 and the iron core unit 2 together form an inner cavity wrapping the excitation coil assembly 1 .

[0048] The lower end surface of the clearing plate 32 is in the sam...

Embodiment 3

[0050] The structural composition of the magnetic track brake of embodiment 3 is basically the same as that of the magnetic track brake of embodiment 1, and the distinguishing features are:

[0051] Each force transmission assembly 4 includes an iron core connection part 41 , a bogie connection plate 42 and a force transmission part 43 .

[0052] The iron core connecting part 41 is composed of two connecting plates 41-1 symmetrically arranged left and right with respect to the vertical surface 51 of the track. One. Connection through holes are provided at the positions corresponding to the bolt connection holes of the connecting plate 41 - 1 and the iron core unit 2 , and the connecting plates 41 - 1 on both sides are fixedly connected with the iron core unit 2 by bolts.

[0053] The bogie connecting plate 42 protrudes from the end of the transverse rib 41-2, and the left and right ends of the bogie connecting plate 42 are fixedly connected with the upper surface of the conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com