Buried type automatic aircraft traction system and traction method

An aircraft traction and buried technology, applied in the field of traction systems, can solve the problems of unstable guarantee timeliness, high operating costs, low process and labor efficiency, etc., and achieve the effects of saving manpower, low operating costs, and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

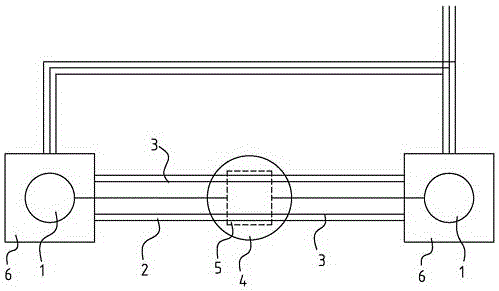

[0042] Such as figure 1 As shown, a buried automatic aircraft traction system includes: an underground passage 2, a carrying frame 5, a carrying turntable 4, a driving mechanism, a shielding device, a control system and a power supply.

[0043] Such as figure 1 , 2 As shown in , 4, the underground passage 2 is buried in the foundation pit 6 at both ends of the apron underground penetration system for installing the driving mechanism. The length of the underground passage 2 is about 60 meters, and the width and depth are 0.6*0.6 meters respectively. The wall and bottom are required to be flat and firm, which can realize the installation and fixation of various connectors and withstand various gravity and tension. There is a certain angle between the underground passage 2 and the main taxiing line 7, the purpose is to force the nose of the aircraft to gradually deflect when the carrier frame 5 slides along the track laid in the underground passage 2, and finally the longitudin...

Embodiment 2

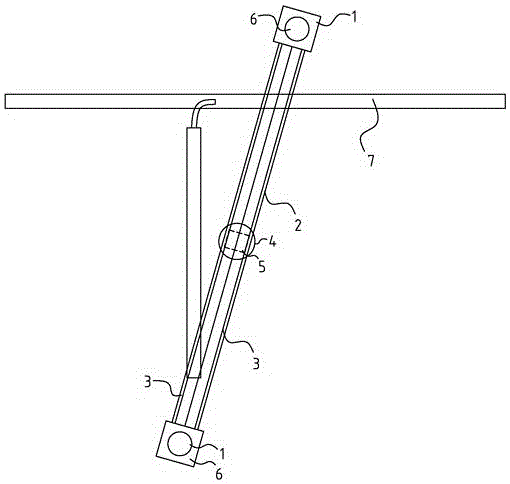

[0056] Such as figure 2 As shown, a buried automatic aircraft traction system includes: an underground passage 2, a carrying frame 5, a carrying turntable 4, a driving mechanism, a shielding device, a control system and a power supply.

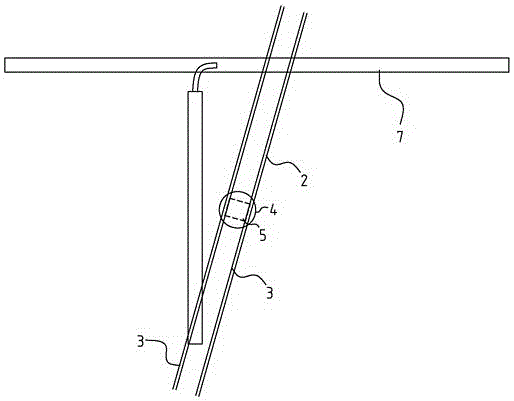

[0057] Such as image 3 As shown, the underground passage 2 runs in a straight line, extends from the stop position and runs through the main taxiing line 7 . The length of the underground passage 2 is about 60 meters, and the width and depth are 0.6*0.6 meters respectively. The wall and bottom are required to be flat and firm, which can realize the installation and fixation of various connectors and withstand various gravity and tension. There is a certain angle between the underground passage 2 and the main taxiing line 7, the purpose is to force the nose of the aircraft to gradually deviate when the carrier frame 5 slides along the track 3 laid in the underground passage 2, and finally the longitudinal line of the aircraft is close to ove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com