Vehicle-mounted telescopic belt conveyor

A telescopic belt conveyor and vehicle-mounted technology, which is applied in the direction of conveyors, steering mechanisms, vehicle components, etc., can solve problems such as reducing the service life of tires and axles, slipping wheels, and large internal forces, so as to improve construction efficiency and flexibility Sexuality and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

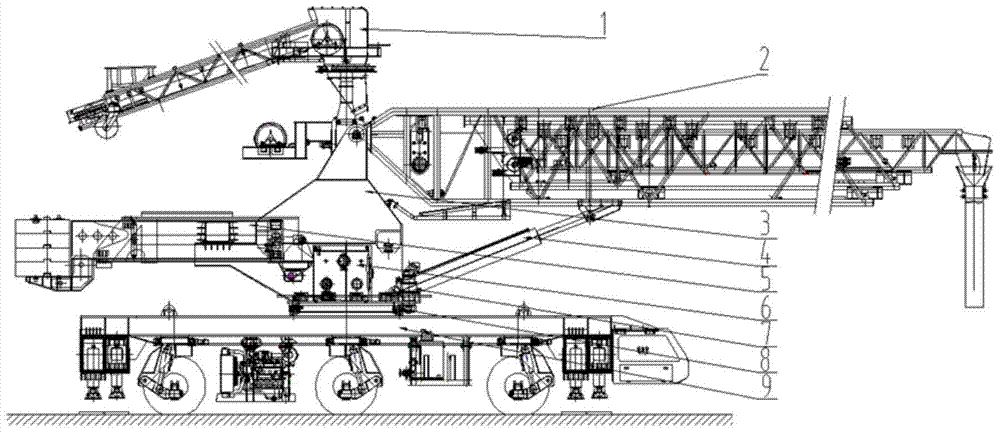

[0034] see figure 1 , shows the vehicle-mounted retractable belt conveyor of the present invention.

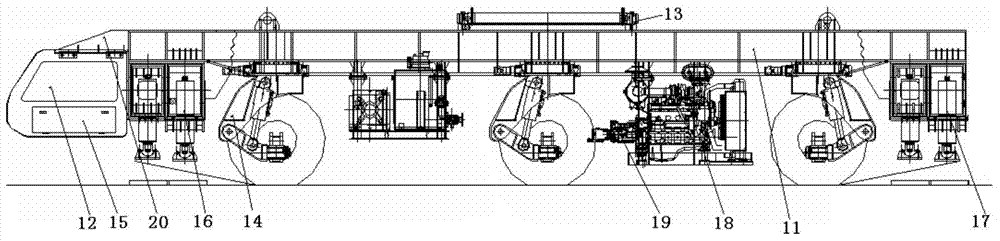

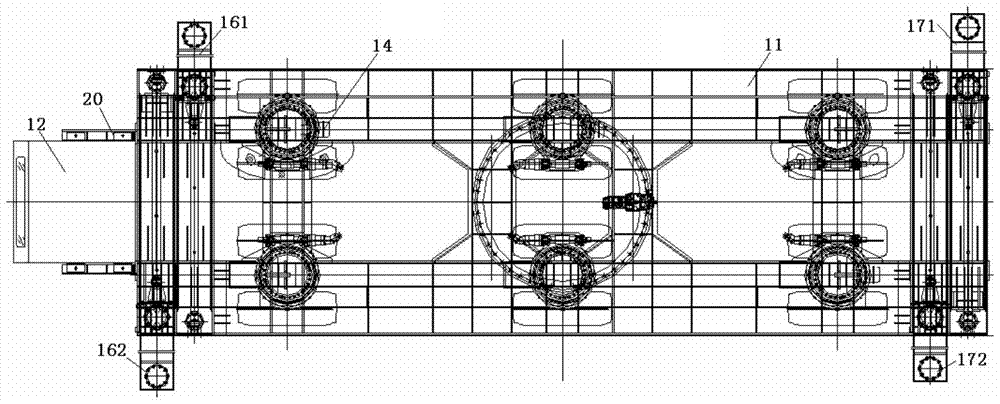

[0035] The vehicle-mounted telescopic belt conveyor includes a driving chassis 9 and an operating system arranged on the driving chassis, the operating system includes a feeding system 1, a cloth boom 2 and a rotary turntable 3, and the rotary turntable 3 passes through A slewing support 8 is installed and fixed on the driving chassis 9, a feeding system 1 is set on the rotary table 3, and the feeding system 1 includes a feeding belt and a feeding hopper, and the feeding hopper is located on the feeding One side of the belt is used to lower the conveyed materials. One end of the feeding system is connected to the top of the rotary table 3 through a pin shaft, and the other end can be placed on the ground through universal wheels. The distribution arm 2 is Truss structure, the cloth boom 2 includes a base arm, an intermediate arm and a forearm that expand and contract in seque...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com