Method for controlling dump cart for multiple groups of stock bins

A technology of unloading trolley and control method, which is applied in the field of silo unloading trolley, which can solve problems such as tight maintenance time, poor site environment, and failure to normally feed materials, so as to improve accuracy and reliability, improve labor efficiency, and reduce personal injuries. damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solutions provided by the present invention will be described in detail below in conjunction with specific examples. It should be understood that the following specific embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

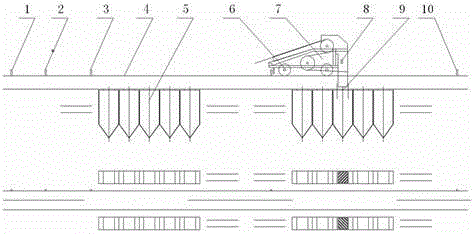

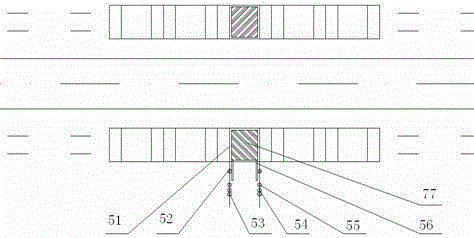

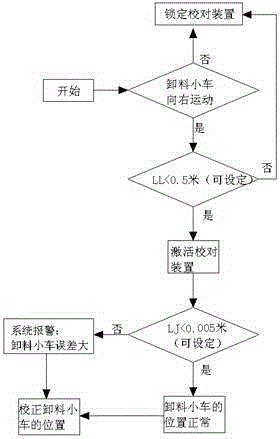

[0024] Such as Figure 1 to Figure 7 As shown, the present invention discloses a control method for a multi-group silo unloading trolley, comprising the following steps:

[0025] 1. Safety protection: such as figure 1 , the left and right limit positions are installed on both sides of the track, use the "closed point", input the PLC system signal as "1", and use the "green" small circle on the HMI screen of the host computer to indicate that the signal is "1", when unloading When the corresponding stopper on the trolley touches the limit or a limit fault occurs, the PLC system detects that the limit signal is "0", which is indicated by a small "red" circle on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com