An intelligent disc tension device and its applied precision winder

A tensioning device and tensioning technology, applied in the directions of transportation and packaging, conveying filamentous materials, thin material processing, etc., can solve the problem of the implementation of subsequent processes affecting the quality of the final package, the inability to perform effective compensation, and the complex sources of yarn tension, etc. problems, to achieve the effect of new design, good molding, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

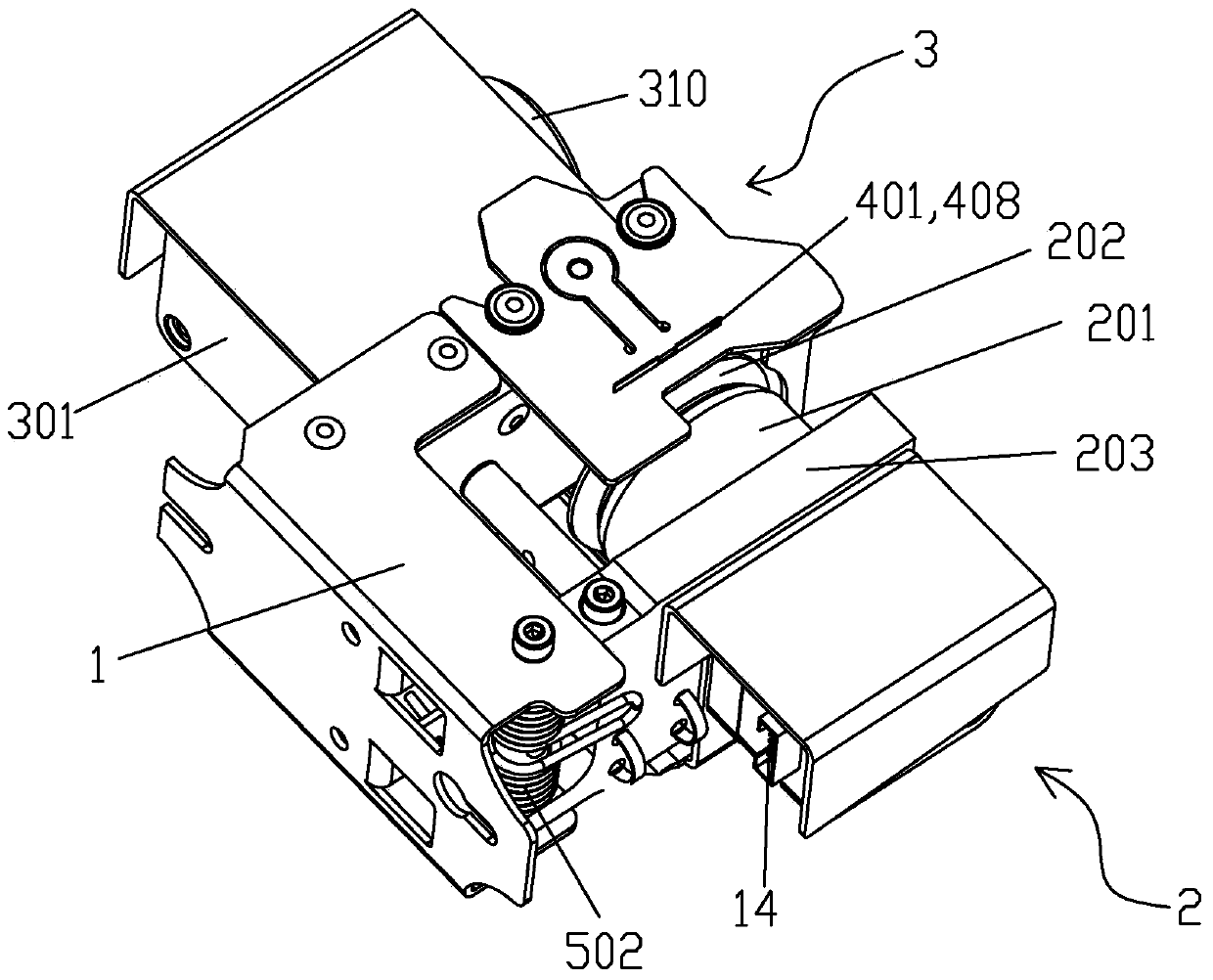

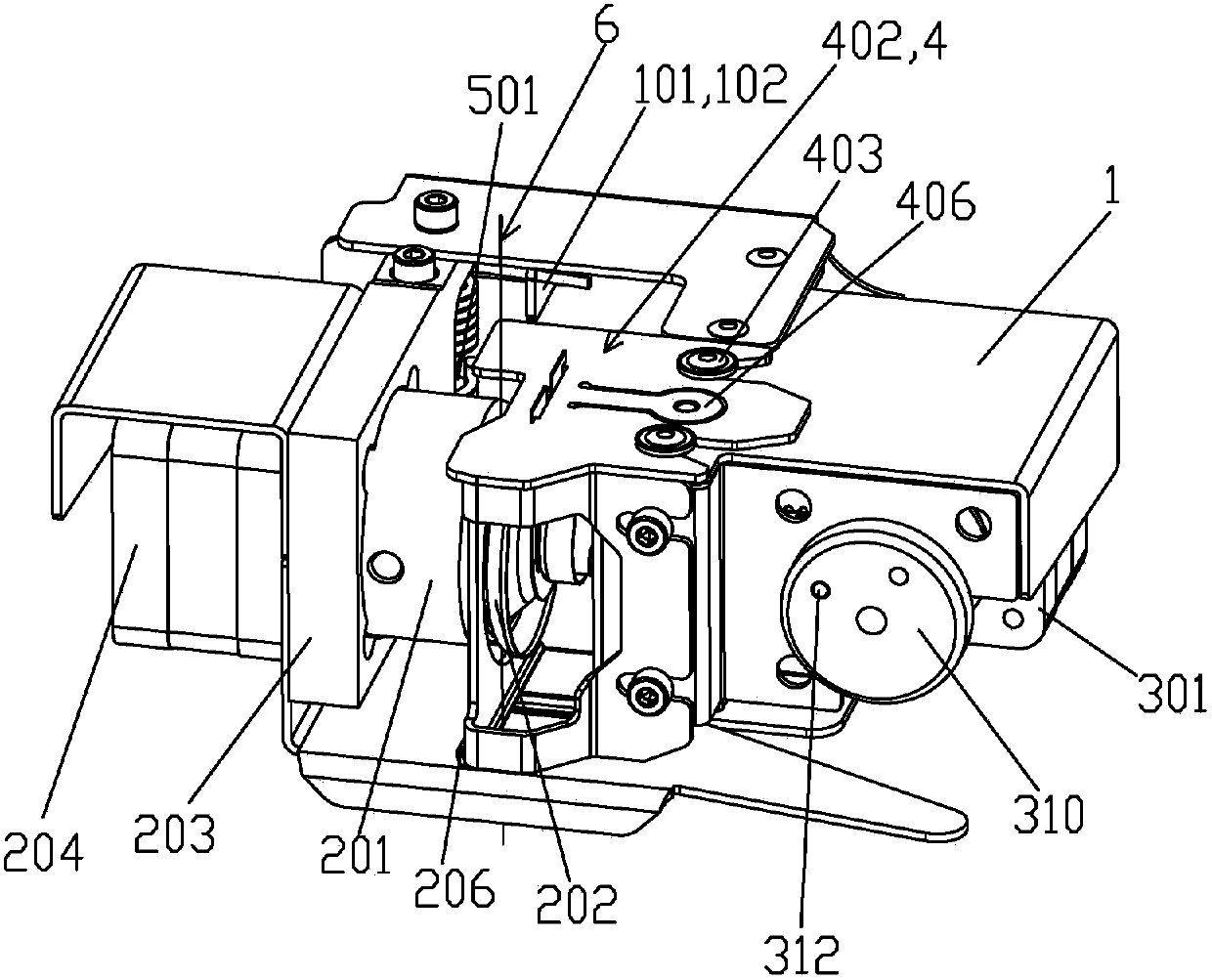

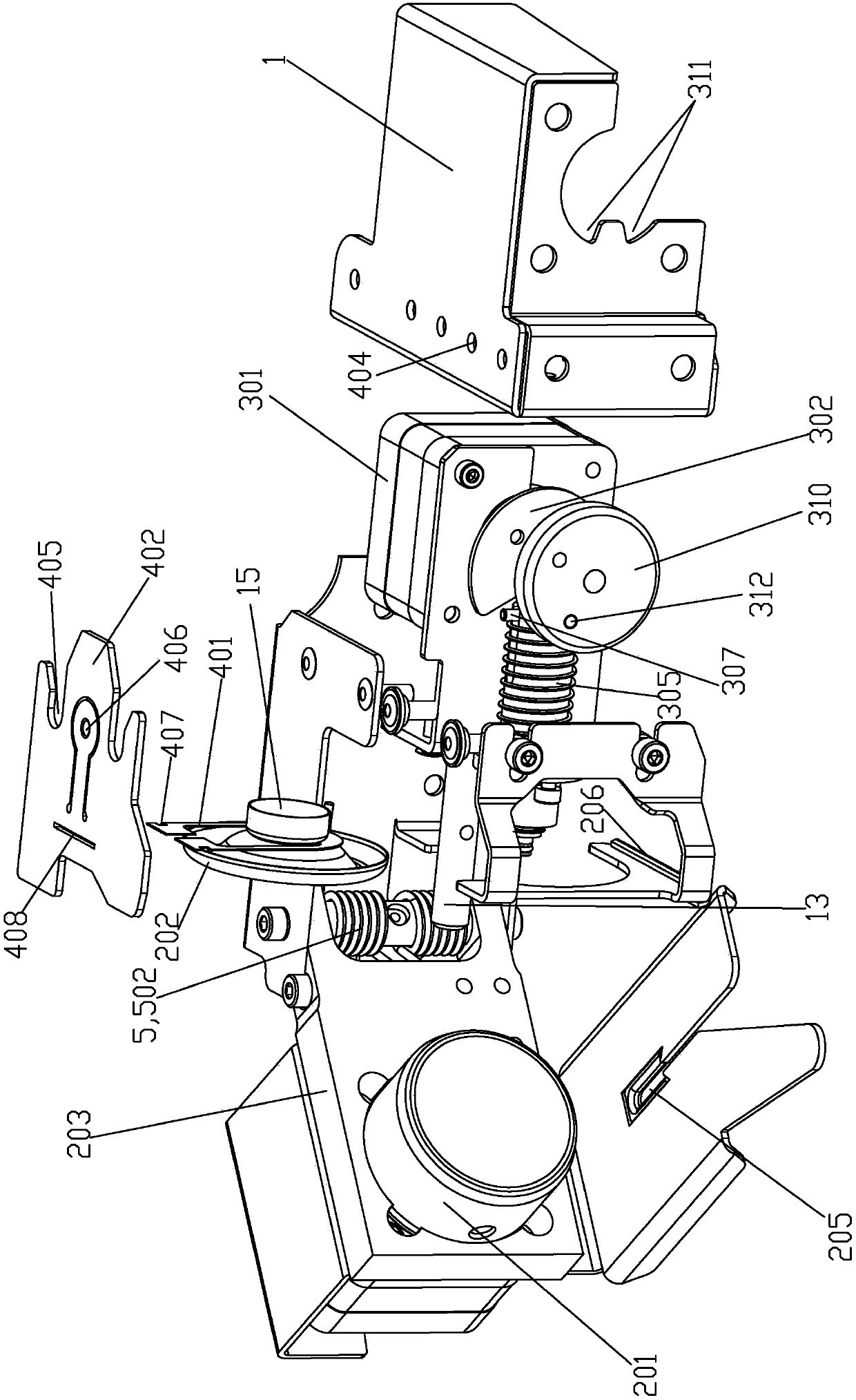

[0033]The technical features of the present invention will be further described in detail below in conjunction with the accompanying drawings to facilitate the understanding of those skilled in the art.

[0034] An intelligent disc tension device, including a support 1, a yarn guide assembly 2 and a tension adjustment assembly 3 provided on the support 1, the yarn guide assembly 2 includes a tension disc 201 arranged on the support 1 and a tension disc 201 cooperates with the tension disc 202, the gap between the tension disc 201 and the tension disc 202 has a guiding effect on the movement of the yarn 6, and the tension adjustment assembly 3 includes a servo that can automatically change the speed according to the received signal The motor 301 is fixedly connected to the output shaft of the servo motor 301 with a cam disc 302 that rotates with the output shaft and drives the tension disc 202 to collide with the tension disc 201 to generate tension. The bracket 1 is formed int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com