Disassembly method of optical crystal assembly based on cantilever

A technology of optical crystal and disassembly method, which is applied to cranes and other directions, can solve problems such as complicated lifting operations, and achieve the effects of compact structure, convenient and reliable lifting, and flexible movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

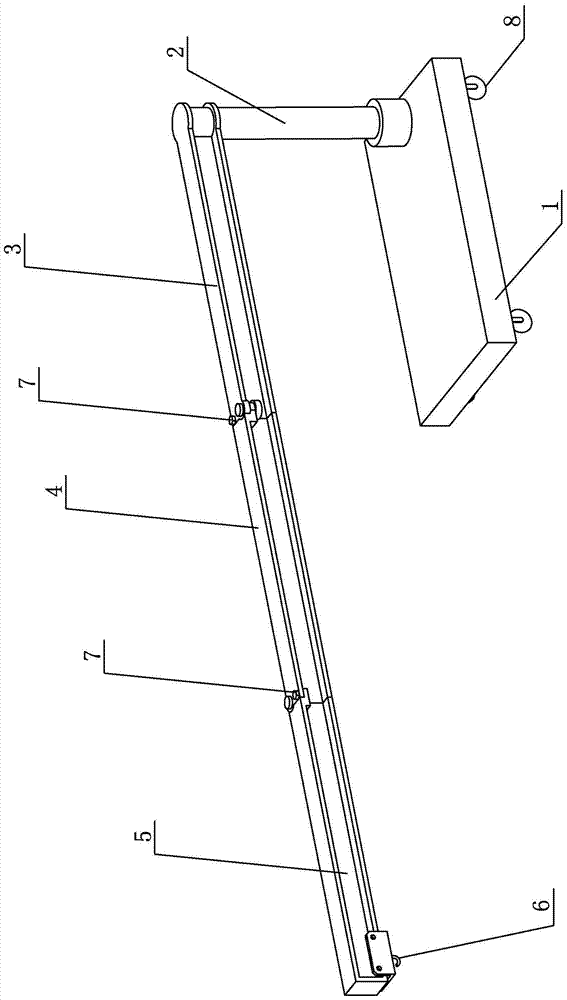

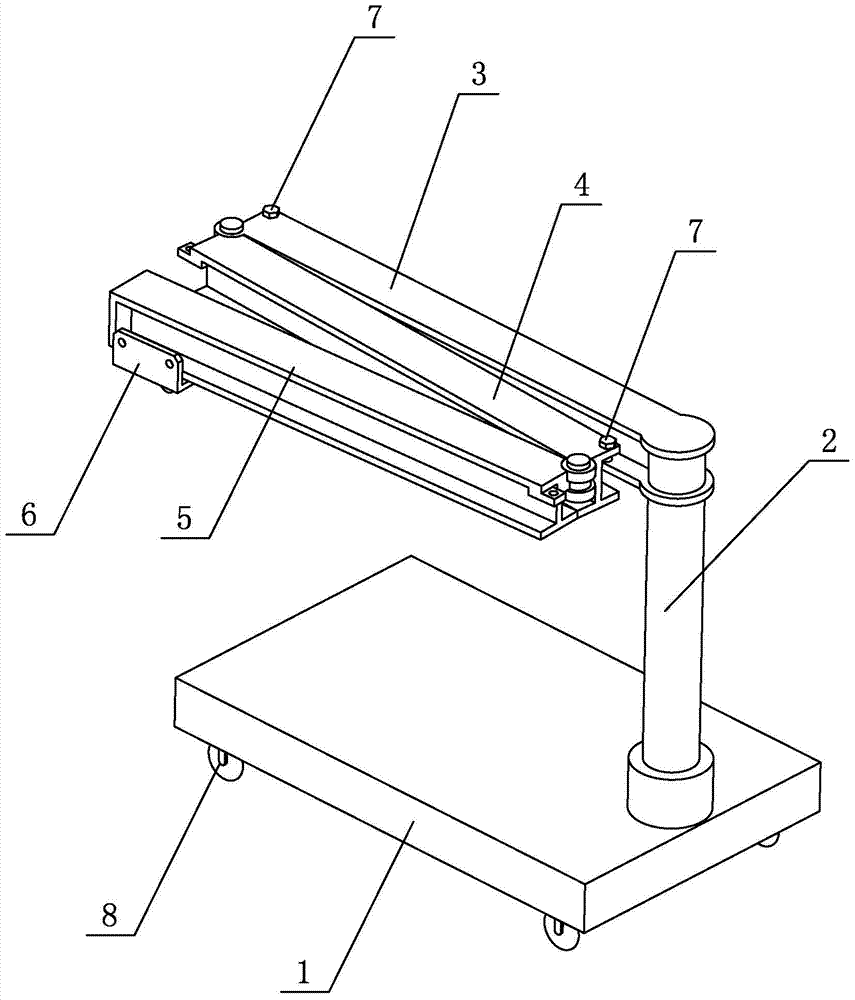

[0007] Specific implementation mode one: combine figure 1 and figure 2 Describe this embodiment, the disassembly method of the cantilever-based optical crystal assembly described in this embodiment includes a base 1, a column 2, a first cantilever 3, a middle cantilever 4, an end cantilever 5 and a hook 6, and the base 1 is horizontally arranged The rectangular plate body, the column 2 is vertically installed on the upper surface of one end of the base 1, one end of the first section of the cantilever 3 is connected to the upper end of the column 2, the other end of the first section of the cantilever 3 is rotationally connected with one end of the middle cantilever 4, and the middle cantilever The other end of 4 is connected with one end of the end cantilever 5, and the other end of the end cantilever 5 is provided with a hook 6.

specific Embodiment approach 2

[0008] Specific implementation mode two: combination figure 1 and figure 2 To illustrate this embodiment, the disassembly method of the cantilever-based optical crystal assembly described in this embodiment also includes two locking bolts 7, and the other end of the first cantilever 3 is connected to one end of the middle cantilever 4 through a locking bolt 7 , the other end of the middle cantilever 4 is connected with one end of the end cantilever 5 through a locking bolt 7 . Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0009] Specific implementation mode three: combination figure 1 and figure 2 To illustrate this embodiment, four moving rollers 8 are arranged on the lower surface of the base 1 based on the method of disassembling and assembling the cantilever optical crystal assembly in this embodiment, and the four moving rollers 8 are arranged in a rectangular shape. Other compositions and connections are the same as those in Embodiment 1 or 2.

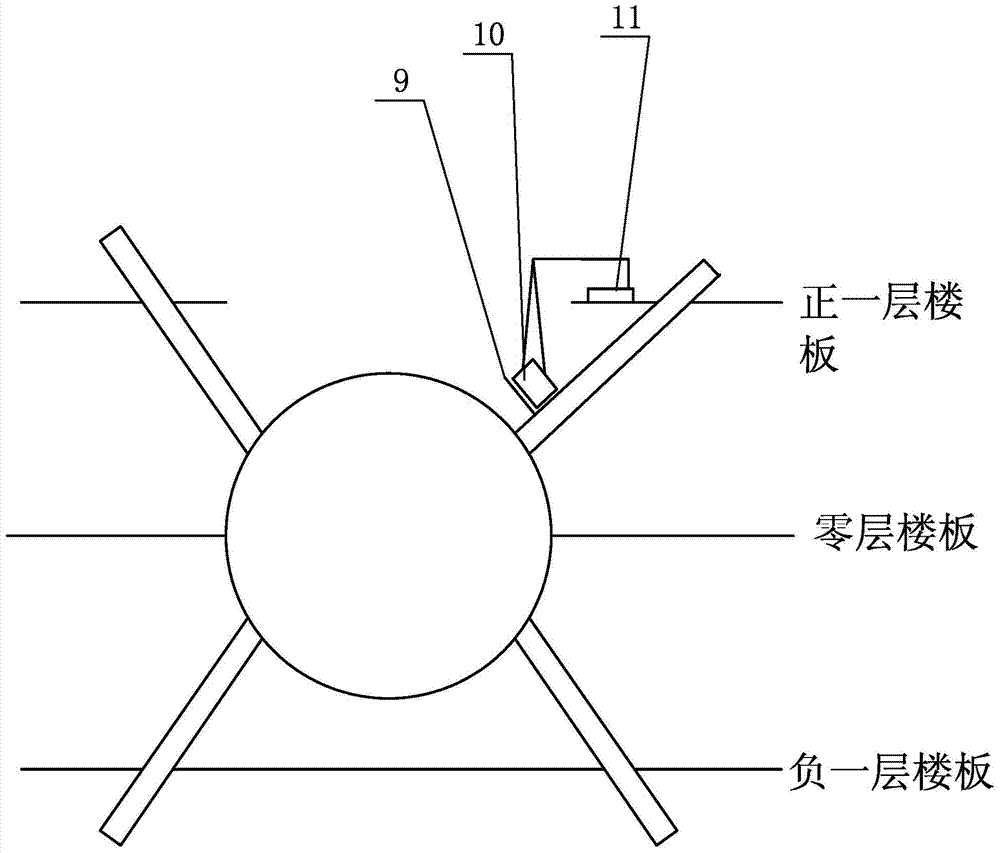

[0010] combine image 3 and Figure 4 Describe the installation steps of optical crystal components:

[0011] Step 1. The first cantilever 3, the middle cantilever 4, and the end cantilever 5 of the present invention are folded, and the cantilever disassembly system 11, the support frame 9, and the clean box 10 are transported to the shooting range, and installed on the first floor of the shooting range. location;

[0012] Step 2, unfold the first cantilever 3, the middle cantilever 4, and the end cantilever 5, respectively insert the lockin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com