A far-infrared heating chlorine dioxide generator

A chlorine dioxide and far-infrared technology, applied in chlorine oxide and other directions, can solve the problems of reduced reliability and safety of generators, hindered gas phase removal of chlorine dioxide, complicated manufacturing and control, etc. The effect of improving the performance and reducing the processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

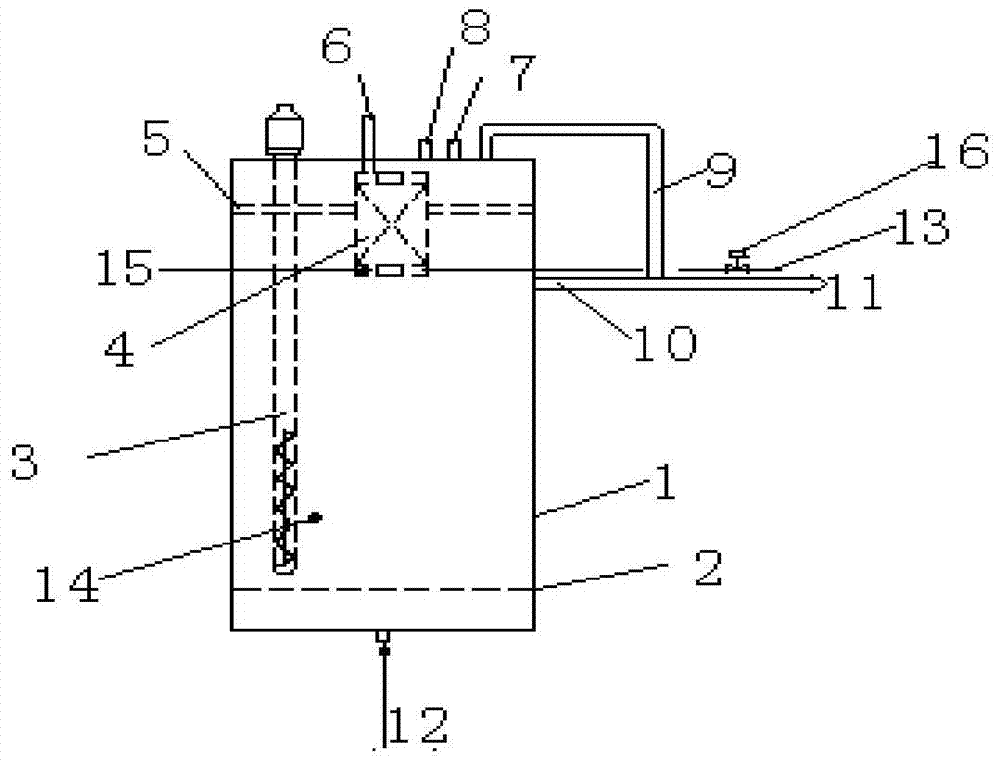

[0034] Such as figure 1 with image 3 As shown, a far-infrared heating chlorine dioxide generator of the present invention includes a main reactor 1, an aeration pan 2, a far-infrared quartz heater 3, a low-temperature reactor 4, a support frame 5, a raw material feeding pipe 6, an outlet Air pipe 9, liquid outlet pipe 10, suction pipe 11, aeration pipe 12 and air conditioning pipe 13; top and goes deep into the reactor 1, the low temperature reactor 4 is installed inside the main reactor 1, and is fixed on the inner upper part of the main reactor 1 by the support frame 5, and the raw material feed pipe 6 passes through after the top of the main reactor 1 It is connected with the top of the cryogenic reactor 4, the outlet pipe 9 is arranged on the top of the main reactor 1, the liquid outlet pipe 10 is arranged on the top of the main reactor 1 and extends into the inside of the main reactor 1, and the suction pipe 11 is respectively It communicates with the gas outlet pipe 9...

example 2

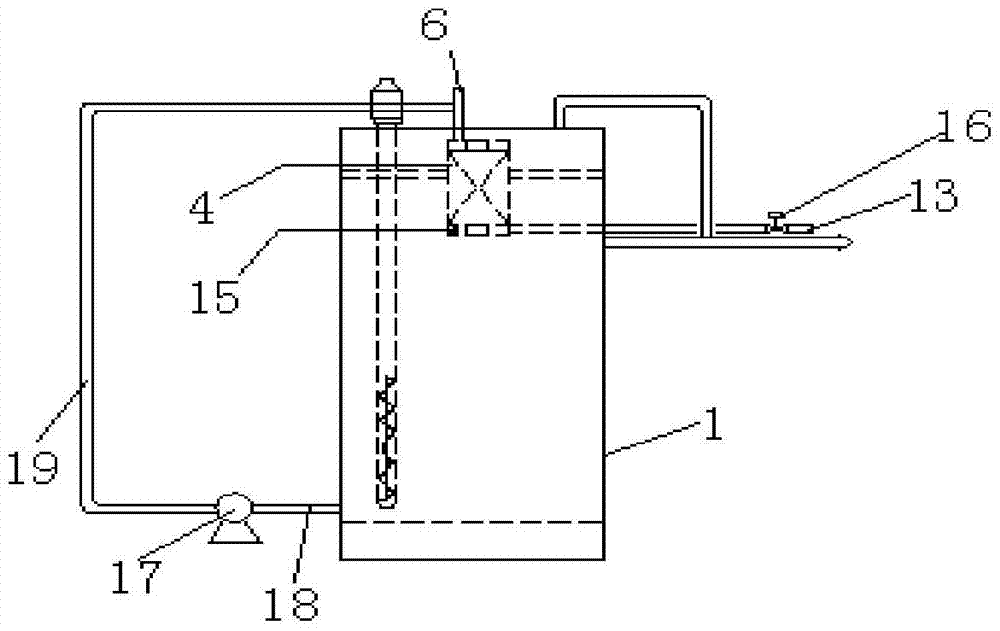

[0040] This example is basically the same as Example 1, the difference is, such as figure 2 with image 3 As shown, the main reactor 1 in this example is also provided with a mother liquor circulation system connected with the low temperature reactor 4 . This circulation system comprises mother liquid circulating pump 17, and the feeding port of mother liquid circulating pump 17 is communicated with the bottom of main reactor 1 by mother liquid discharge pipe 18, and the discharge port of mother liquid circulating pump 17 is fed into raw material by mother liquid feeding pipe 19. The feed pipe 6 is connected. When the circulation system is in operation, the mother liquor in the main reactor 1 enters the low-temperature reactor 4 after passing through the mother liquor discharge pipe 18, the mother liquor circulation pump 17 and the mother liquor feed pipe 19 and the raw material feed pipe 6 successively. On the one hand, the incompletely reacted raw materials in a part of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com