High gravity reverse osmosis solution separation device and method

A separation device and separation method technology, applied in reverse osmosis, non-polluting water treatment, seawater treatment and other directions, can solve the problem of high price of liquid energy recovery device, and achieve the effect of high technical and economic value and simple system structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

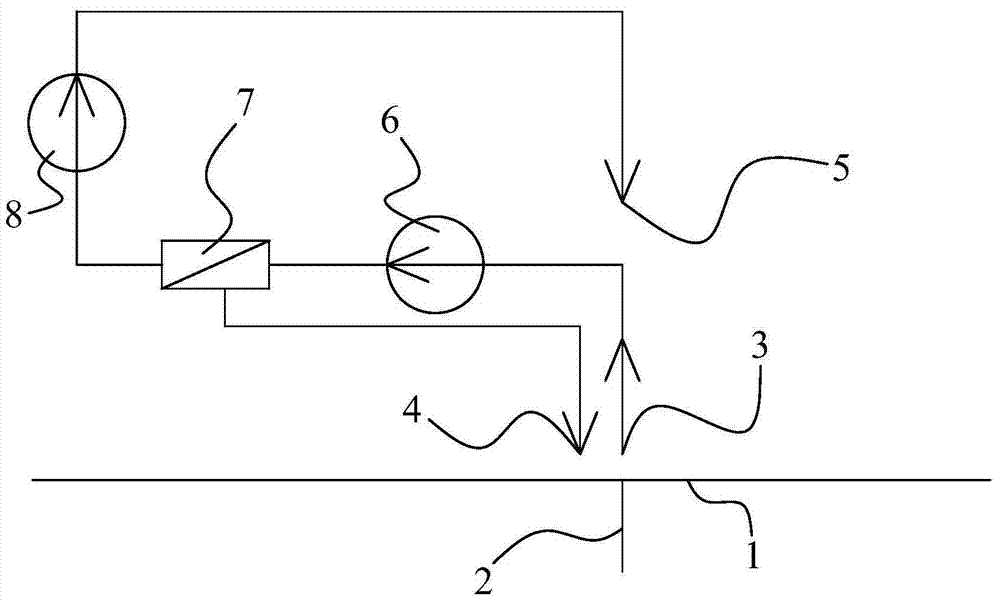

[0019] Embodiment 1, figure 1 A high-gravity reverse osmosis solution separation device and method are provided. The high-gravity reverse osmosis solution separation device comprises a rotating shaft 2, which is provided with a base 1; on the base 1, a high-pressure pump 8, a reverse osmosis device 7, a solution pump 6, pipeline A, pipeline B, and pipeline C (through the base 1 The high-pressure pump 8, the reverse osmosis device 7, the solution pump 6, the pipeline A, the pipeline B and the pipeline C) which can be stably arranged on the rotating shaft 2.

[0020] The liquid inlet of solution pump 6 is provided with a dilute solution inlet 3 through pipeline A; the liquid outlet of solution pump 6 is connected to the liquid inlet of reverse osmosis device 7; the water outlet of reverse osmosis device 7 is connected to the liquid inlet of high-pressure pump 8; the liquid outlet of high-pressure pump 8 is set through pipeline C There is a pure water outlet 5; the liquid outlet...

Embodiment 1

[0032] The calculation parameters of implementation example 1 are shown in Table 1 (for 1 kg of water). The design conditions are: the radius of gyration of the system is 0.5m, reverse osmosis is performed on seawater, the content of calcium ions in the feed seawater is 360ppm, the content of magnesium ions is 1176ppm, the content of sodium ions is 10065ppm, the content of potassium ions is 366ppm, and the content of sulfate ions is 2480ppm , the chloride ion content is 18152ppm, the temperature is 25°C, the seawater osmotic pressure is 2.4Mpa, the water production rate of the system is 25%, the osmotic pressure of the discharged concentrated seawater is 3.2Mpa, and the average driving pressure difference of the reverse osmosis process is 2.95Mpa, The system speed is 2004 rpm, the power consumption of the high-pressure pump and the solution pump are 6.88kJ / kg and 2.5kJ / kg respectively, and the exergy efficiency of the system (defined as the ratio of the minimum separation work ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com