Continuous feeding device for solution method centrifugal spinning

A technology of centrifugal spinning and feeding device, which is applied in the directions of feeding solution to spinnerets, textile and papermaking, filament/thread forming, etc. problem, to achieve the effect of low cost investment, small space occupation, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

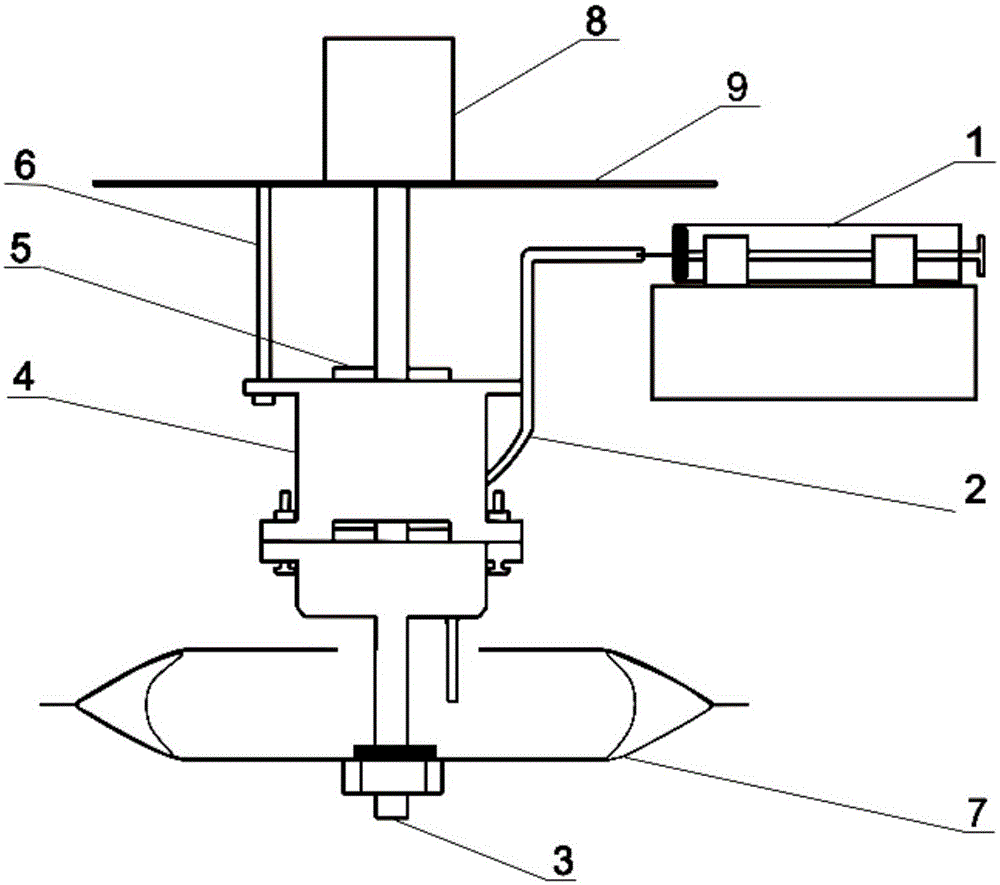

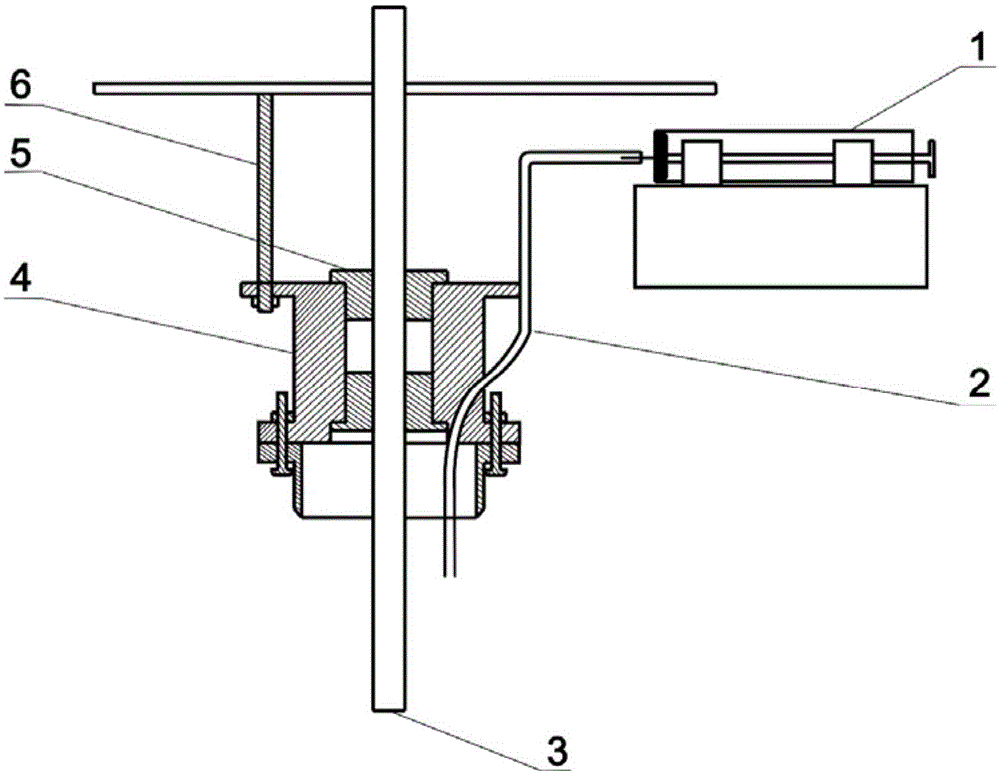

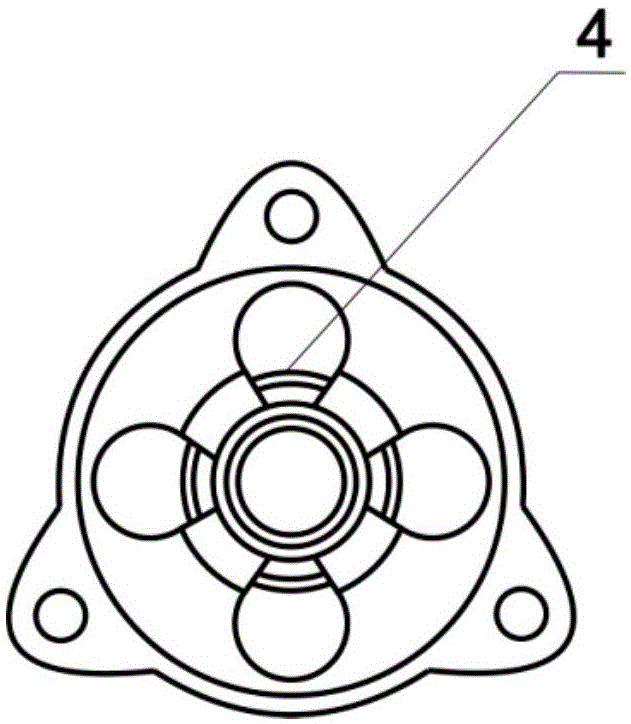

[0016] Such as Figure 1-3 As shown, the continuous feeding device suitable for solution centrifugal spinning includes a motor 8 and a spinneret 7, the motor 8 is arranged on the frame 9, one end of the transmission shaft 3 is connected to the motor 8, and the other end is connected to the spinneret 7 Connect; the hose holder 4 is fixed on the frame 9 through the support rod 6, the inside of the hose holder 4 has a longitudinal through hole, and the two ends of the through hole are in the shape of counterbore; the two ends of the through hole are respectively provided with a bearing 5 , The cross section of the two bearings 5 is in the shape of a boss, matching with the shape of the counterbore at both ends of the through hole. The transmission shaft 3 is installed in the bearing 5 and coincides with the center line of the through hole; a rubber hose 2 passes through the oblique through hole located at the side of the hose holder 4, and the feed port of the rubber hose 2 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com