Construction method of complex geology and environment access to existing support system of subway

A technology with complex geology and systems, applied in artificial islands, water conservancy projects, infrastructure projects, etc., to achieve the effects of increasing stability, saving costs, and reducing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

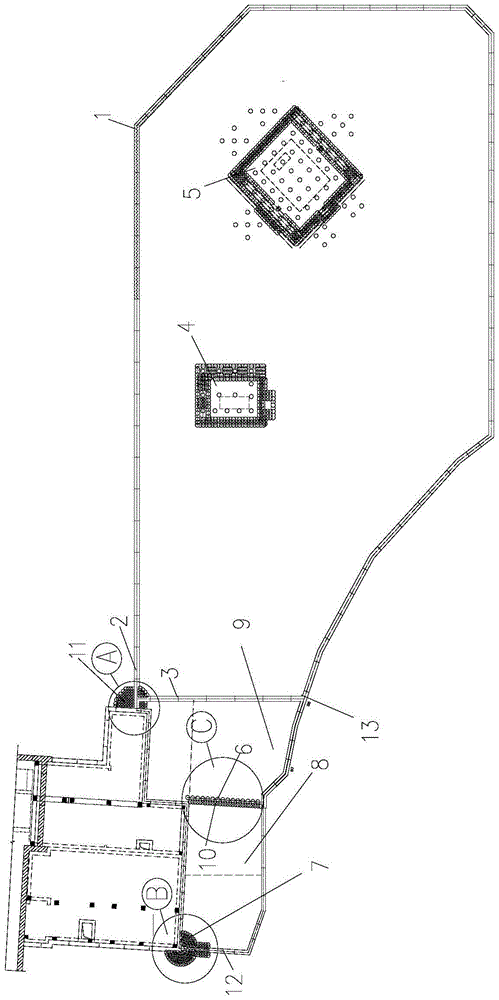

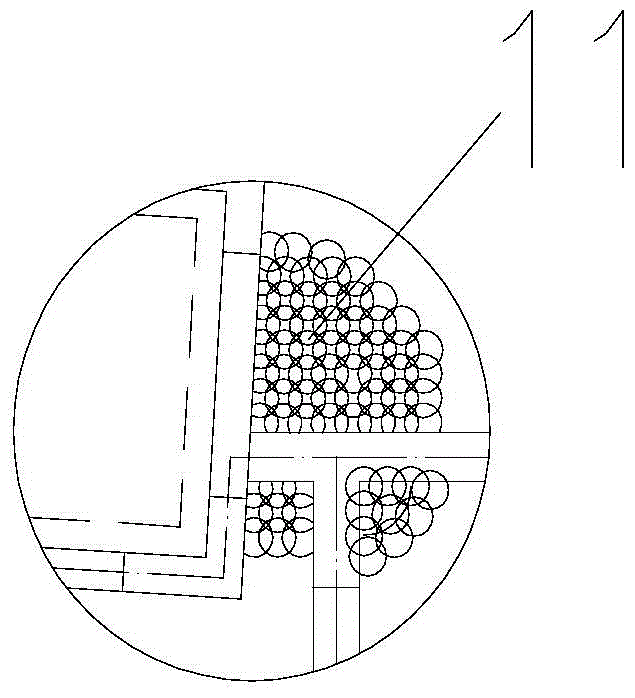

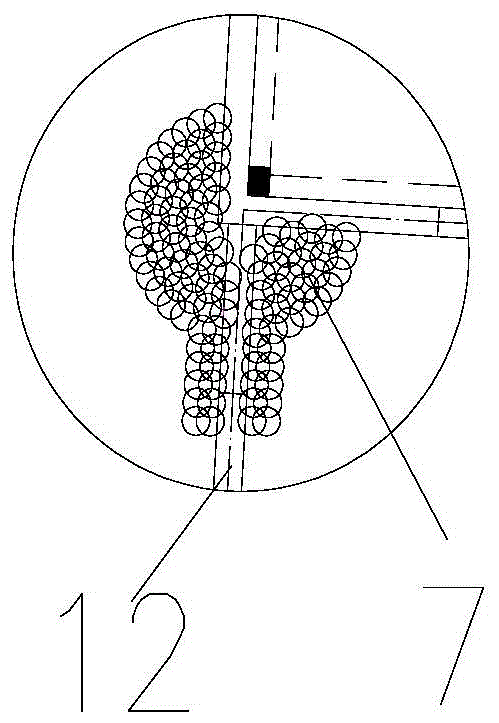

[0032](1) Select a point in the ground connection wall system to be built as the first axis point 1. The principle of selecting the first axis point is based on the actual situation on site. In order to ensure that the construction period is not delayed, the first axis point is far away from the surrounding underground pipelines to be relocated , and at the same time select the first axis point 1 to ensure that there will be no influence of the surrounding buildings during the construction of the ground connection wall to be constructed. Set the two intersecting surfaces of the original support ground connection wall system and the to-be-built ground connection wall system of the original subway station; the original support ground connection wall system and the to-be-built ground connection wall system of the original subway station Select an intersecting surface closest to the first axis point as the first connecting surface, and another intersecting surface as the second con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com