Bi-directional five-drill-bit drilling type coal mining equipment

A five-bit, drill-type technology, which is applied to drilling equipment, earthwork drilling, and driving devices for drilling in boreholes, etc., can solve problems such as wasting time, low work efficiency, and high labor intensity of workers, and achieves easy installation and reduced The effect of mining cost and reducing labor force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] An embodiment of the present invention will be further described below in conjunction with the accompanying drawings:

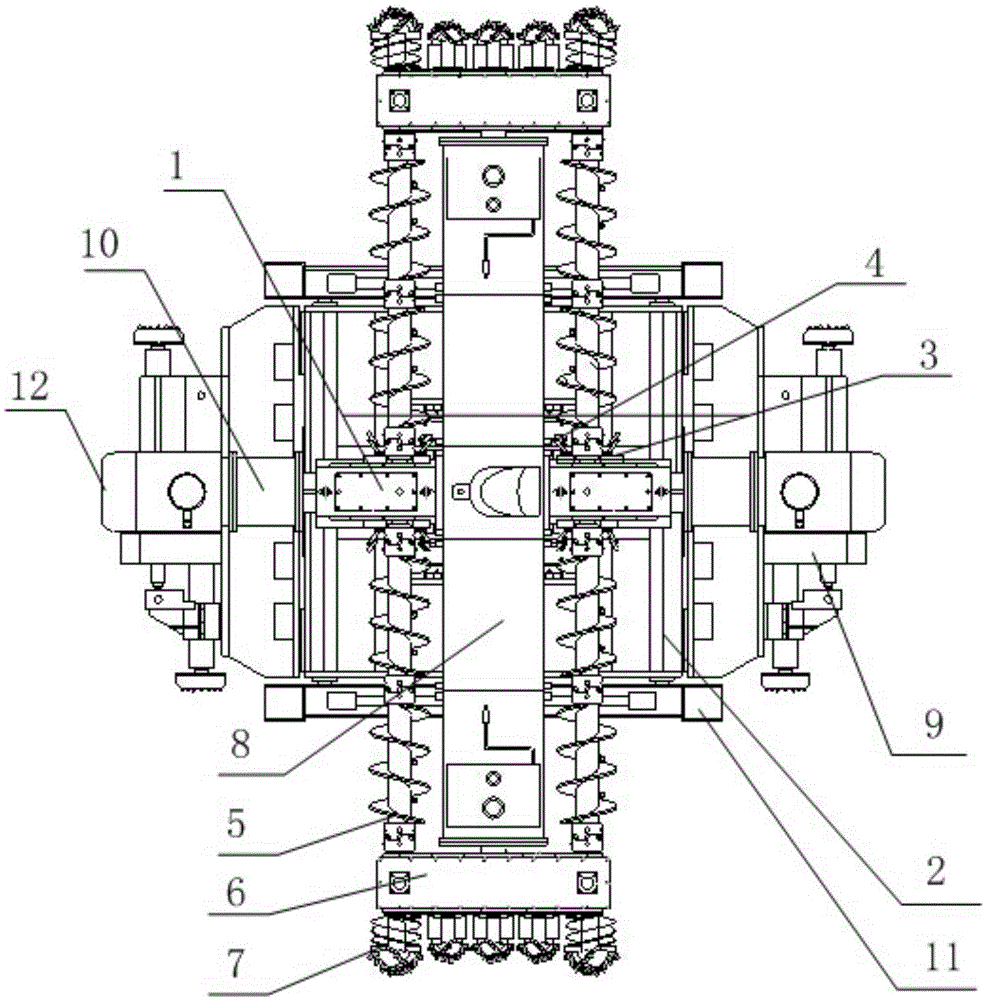

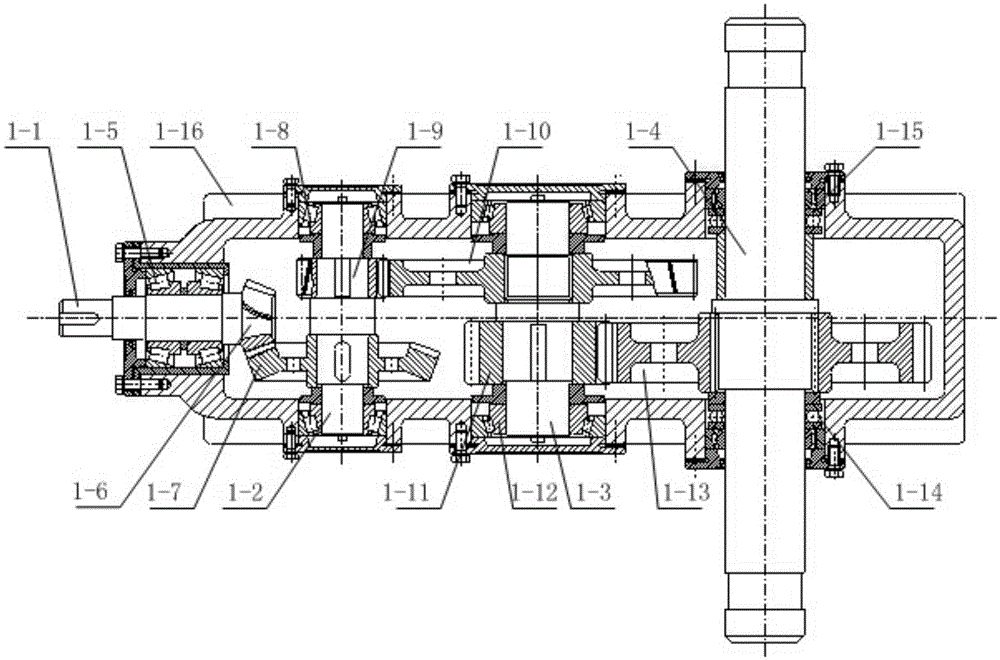

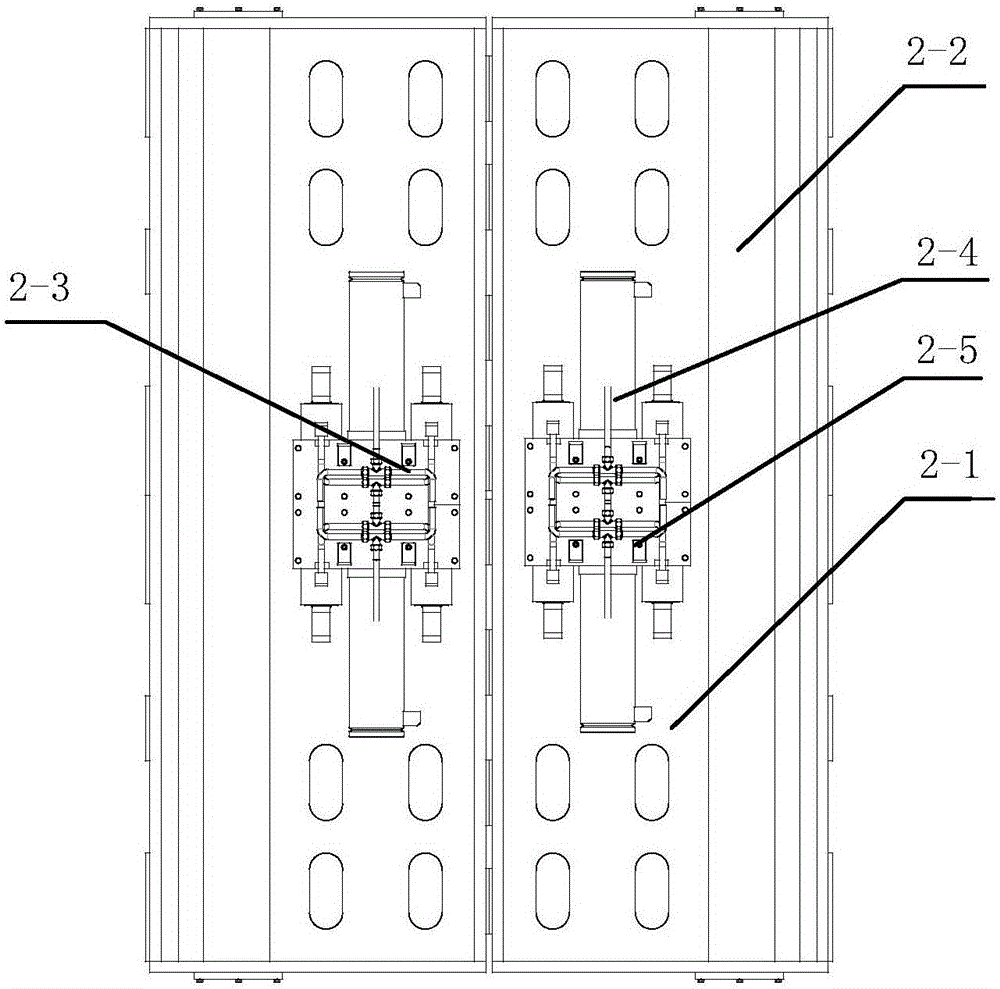

[0017] Such as figure 1 As shown, the two-way five-bit drill type coal mining equipment of the present invention mainly consists of a two-way output reducer 1, a bracket 2, a moving frame 3, a propulsion mechanism 4, an auger rod 5, a transmission case 6, an auger bit 7, and a ventilator 8. Side frame 9, hydraulic coupler 10, front frame 11, and explosion-proof motor 12; The hydraulic coupler 10 is connected to the two-way output reducer 1, the extended end of the two-way output reducer 1 is connected to the auger rod 5, the auger rod 5 is connected to the auger bit 7 through the transmission box 6, and the side frame 9 is symmetrically arranged on the bracket On the left and right sides of the frame 2, the front frame 11 is symmetrically arranged at the upper and lower ends of the bracket 2, and the middle of the mobile frame 3 is connected with a re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com