Natural gas hydrate hole-bottom refrigerating liquid moving rope coring drill tool and coring method

A core drilling tool and hydrate technology, applied in the direction of extracting undisturbed core devices, earthwork drilling and mining, etc., can solve the problems of poor control of cold source injection process, etc., and achieve the goal of improving core recovery rate, avoiding damage, and high feasibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

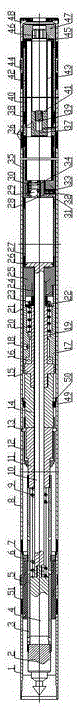

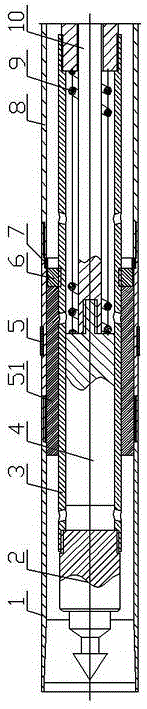

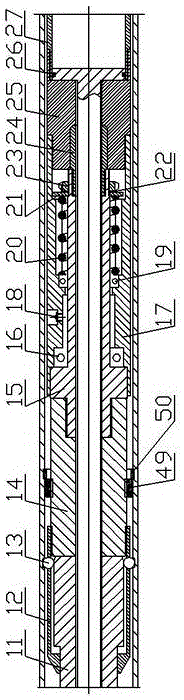

[0029] wall reference figure 1 , figure 2 , image 3 and Figure 4 As shown, the present invention is composed of an inner tube assembly and an outer tube assembly, wherein the inner tube assembly includes a salvage mechanism, a control mechanism, a suspension mechanism, a steel ball positioning mechanism, a single-action mechanism, an adjustment mechanism, and a cold source storage mechanism And the freezing mechanism at the bottom of the hole;

[0030] The salvage mechanism is composed of the spear head 2 and the first inner receiver 3. The spear head 2 and the first inner receiver 3 are connected through threads; In the hole and recovery; drive the core pipe 43 to move upwards during the salvage mechanism.

[0031] The control mechanism is composed of the first inner receiver 3, the control piston 4, the first spring 9, the control valve 10 and the gravity tube 11. The first inner receiver 3 and the gravity tube 11 are connected by threads, and the control piston 4 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com