Wind power generation high-power flexible long-range transmission device

A transmission device and high-power technology, applied in the fields of wind power generation equipment structure and mechanical equipment product structure, can solve the problems of unsuitable long-distance transmission, low power transmission efficiency, large pressure loss, etc., and achieve convenient long-distance motion transmission, reliable The effect of low performance and poor stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

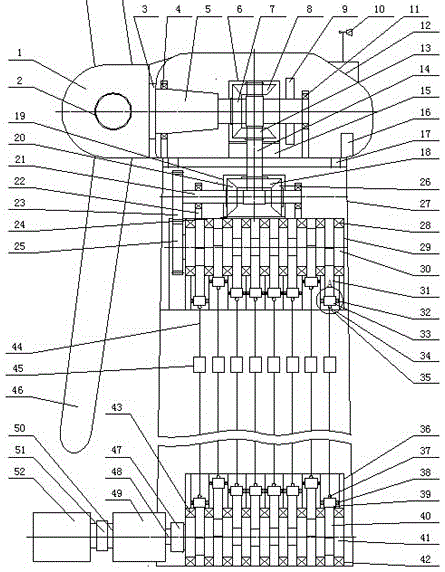

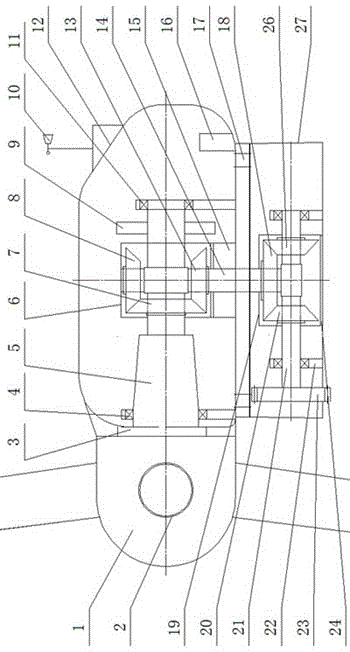

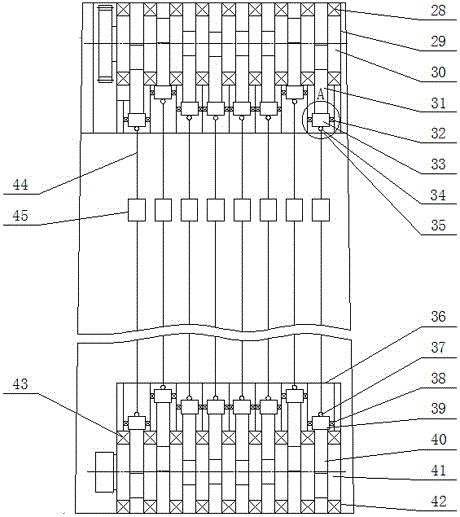

[0013] Such as figure 1 As shown, the present invention is a high-power flexible long-distance transmission device for wind power generation, especially using the crank-slider-cable mechanism to realize the flexible long-distance transmission of the mechanical energy of the wind power generation transmission system, including the wind wheel, the main shaft 5, the nacelle 12, the first stage Speed-up, tower 27, crank-slider-cable mechanism, second-stage speed-up 49 and generator 52, described wind wheel is made up of three blades 46 and hub 1, and blade 46 is installed by flange On the wheel hub 1; the pitch changing device 2 is installed inside the wheel hub 1, the pitch changing device 2 is connected to the blade 46, the rear flange 3 of the wheel hub 1 is connected to the main shaft 5 through bolts, and the main shaft 5 passes through the main bearing seat 4 and the rear bearing The seat 11 is fixed on the bottom plate of the nacelle 12, and the rear end of the main shaft 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com