A dynamic correction device for hydraulic system that can effectively suppress load resonance

A hydraulic system and dynamic correction technology, applied in fluid pressure actuation devices, fluid pressure actuation system testing, servo motor components, etc., can solve problems such as increasing the difficulty of servo valve debugging and increasing the complexity of servo valves, and achieve good results. Hydraulic dynamic damping effect, compact structure and regular shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

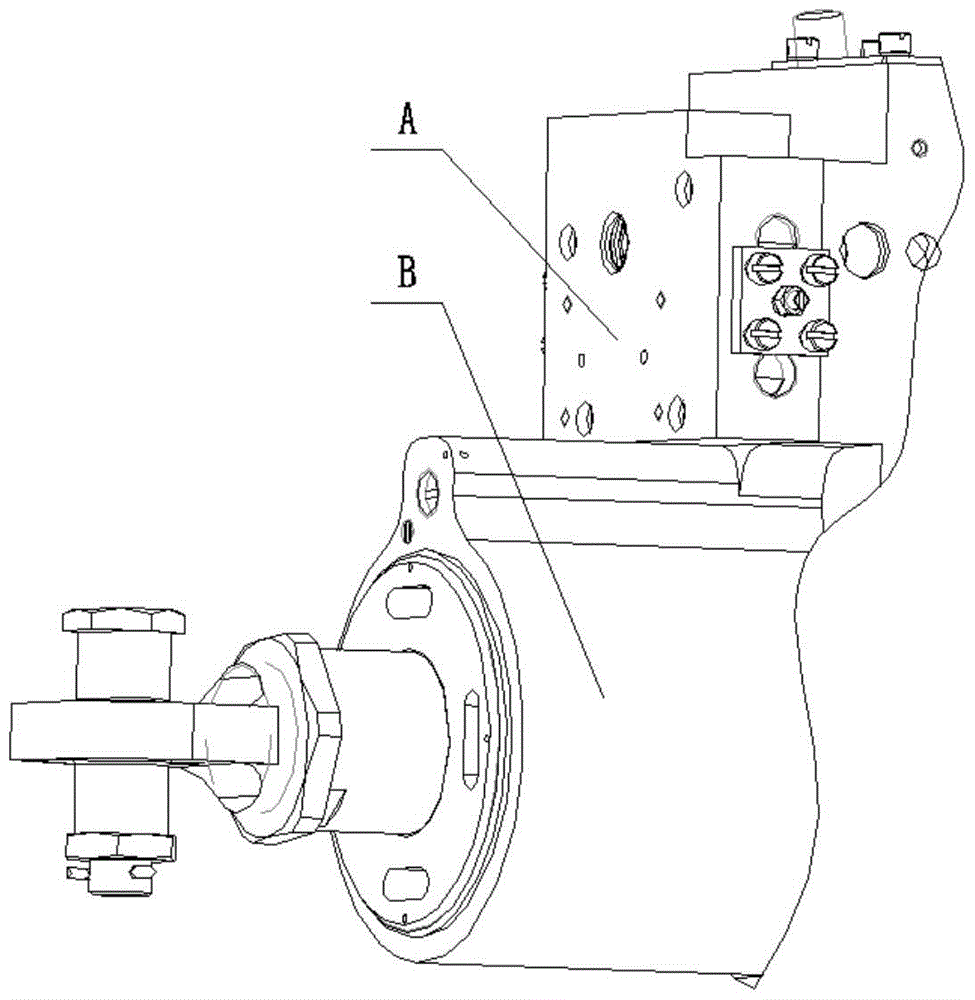

[0061] A hydraulic servo system resonates with the pushed elastic load, and the resonance peak reaches about 5dB. In order to effectively suppress the load resonance peak, a dynamic correction device is designed.

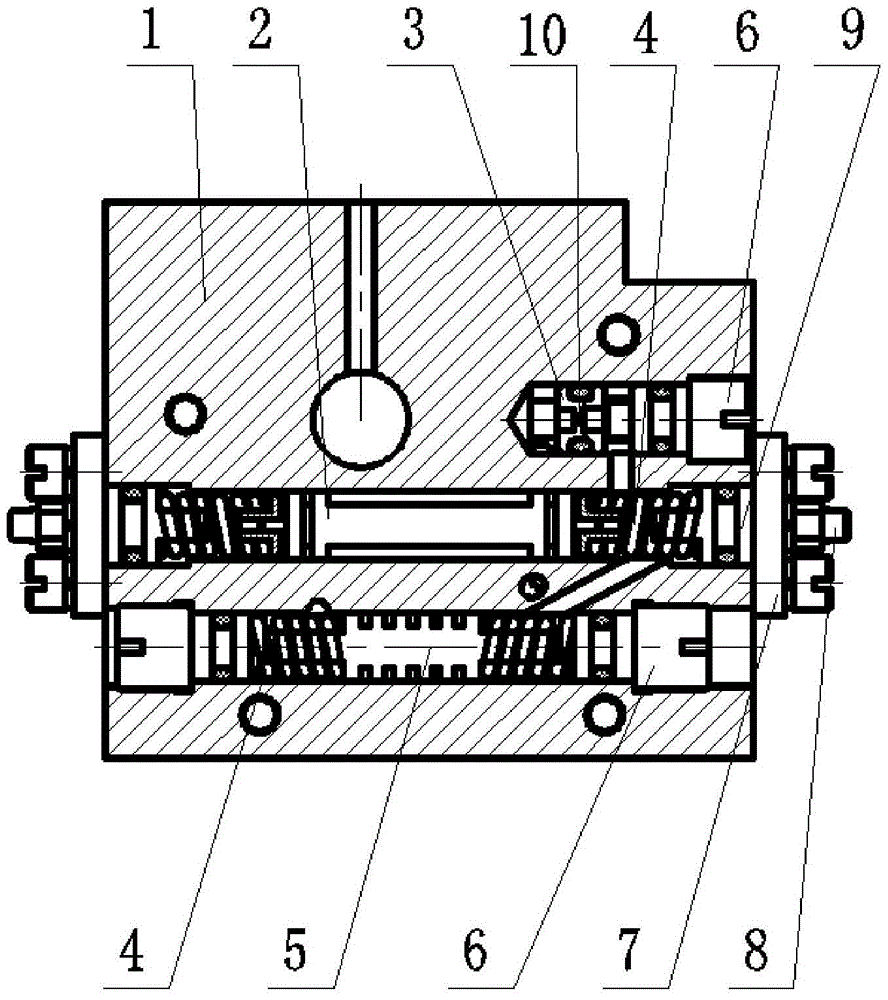

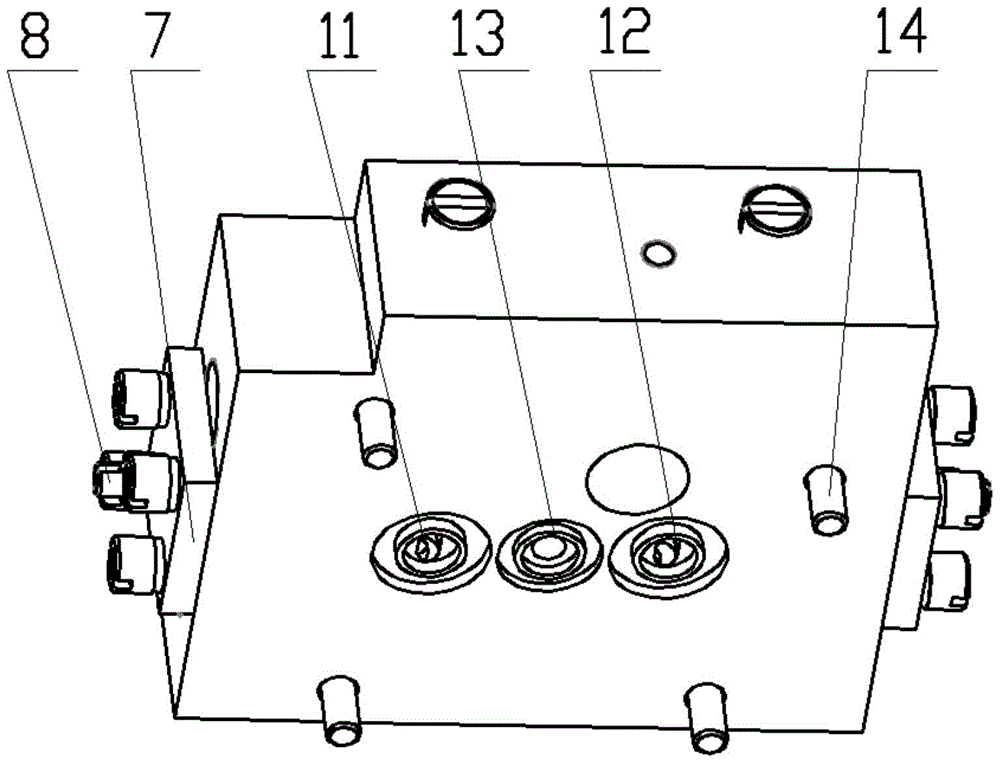

[0062] First, according to the present invention, the housing is 61.5mmX52.5mmX18.5mm. Three parallel holes with a diameter of 6.4 mm are drilled in sequence on the shell. Such as figure 1 As shown, the first hole is a blind hole, which is used for installing the damping hole seat 3, and the diameter of the damping hole is 0.25mm. The second and third holes are both through holes, and the throttle spool and the pressure accumulation spool are installed respectively, and springs 4 with a stiffness of 46N / mm are respectively installed at both ends of the spool. Tighten the plugs 6 on both sides of the pressure accumulation spool, and the stroke of the pressure accumulation spool is about 2mm. During debugging, adjust and adjust the stud 8 to a proper position accor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com