Rotating modulation radial spherical permanent-magnet biased magnetic bearing

A technology of rotation modulation and permanent magnet bias, applied in the directions of bearings, shafts and bearings, mechanical equipment, etc., can solve the problems of reduced pointing accuracy of gyroscopes, unequal electromagnetic force, and reduced accuracy of detection components, to eliminate gyro drift , Eliminate the interference of radial translation control and improve the effect of control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] specific implementation plan

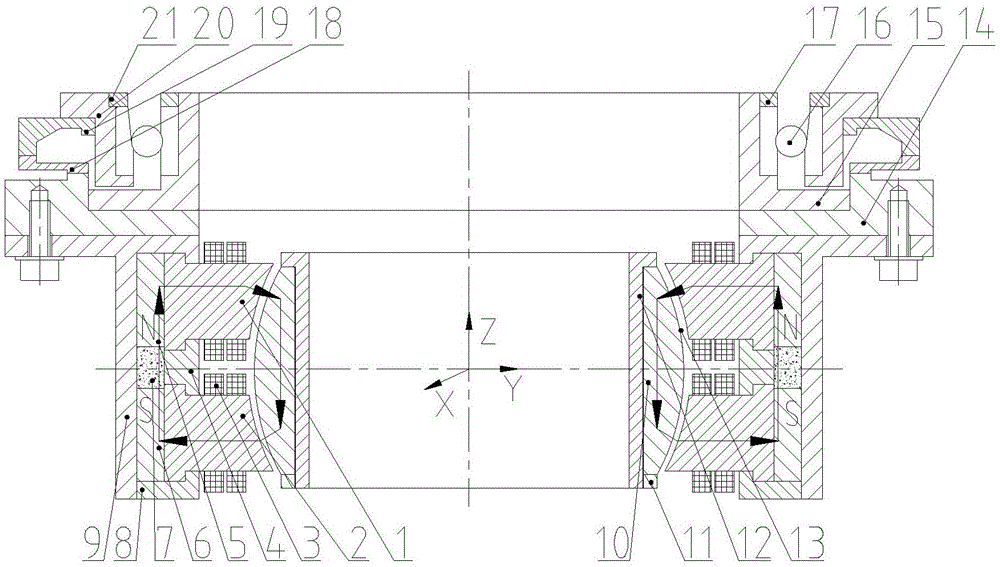

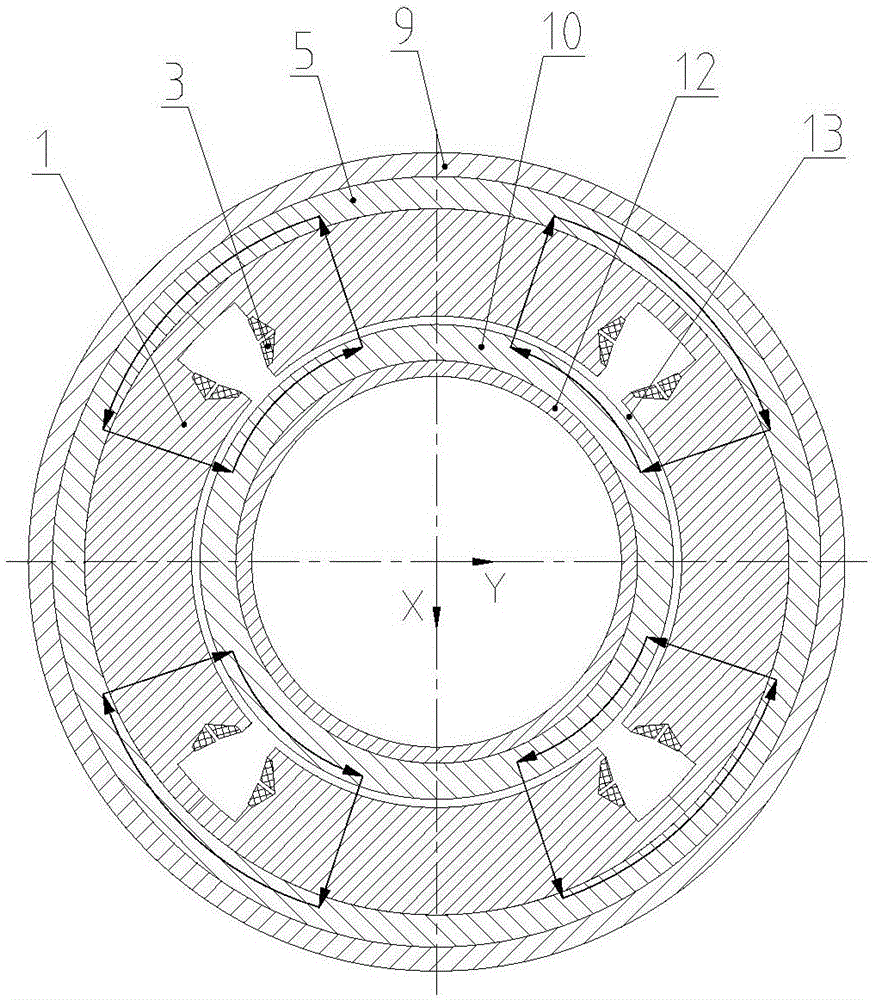

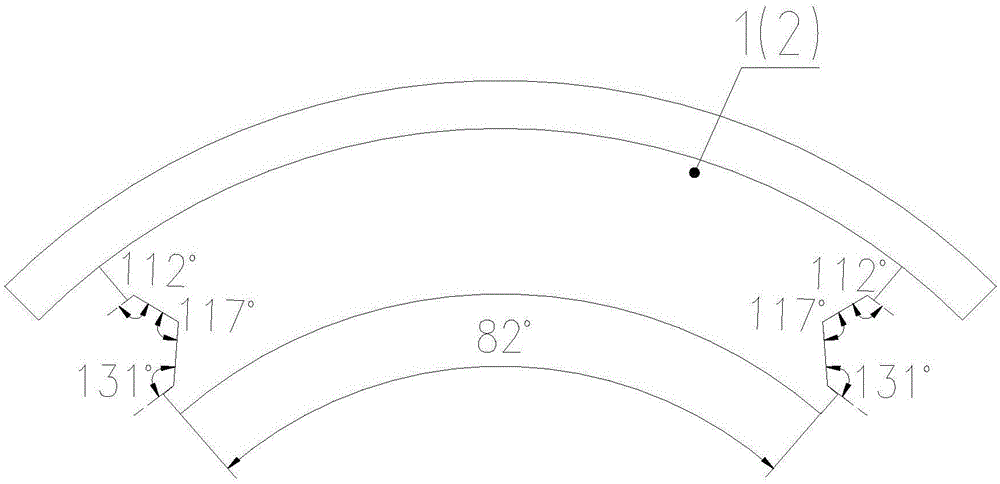

[0021] Such as figure 1 , 2 As shown, a rotation modulation radial spherical permanent magnet bias magnetic bearing is mainly composed of a stator and rotor system and a rotation modulation system, mainly including: four upper spherical stator cores (1), four lower spherical stator cores (2 ), excitation coil (3), magnetic isolation ring (4), upper magnetic ring (5), lower magnetic ring (6), permanent magnet (7), stator lock nut (8), stator sleeve (9) , spherical rotor core (10), rotor lock nut (11), rotor sleeve (12), air gap (13), magnetic bearing stator mounting plate (14), rotation modulation rotor bearing sleeve (15), rotation modulation bearing ( 16), rotation modulation rotor lock nut (17), ultrasonic motor rotor (18), ultrasonic motor stator (19), rotation modulation stator bearing sleeve (20) and rotation modulation stator lock nut (21); four upper spherical surfaces The stator cores (1) are wound with two excitation coils (3) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com