Power conversion device with swing rotation changed into unidirectional rotation

A technology of one-way rotation and power conversion, applied in transmissions, gear transmissions, belts/chains/gears, etc., can solve the problems of low transmission efficiency, low reliability, complex structure, etc., and achieve good reliability and manufacturing cost. Low, small gear transmission coefficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

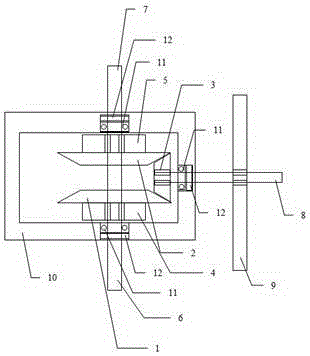

Image

Examples

Deformed example 1

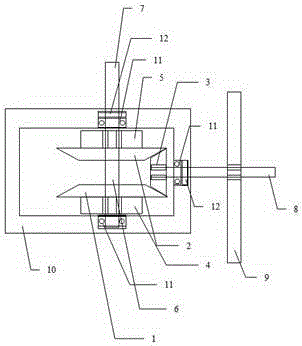

[0016] In the above-mentioned embodiment, an example in which the power input may be unilaterally input or input at the left and right ends with respect to the left half shaft 6 and the right half shaft 7 has been described. However, the present invention does not limit this structure. For example, attach figure 2 As shown, it is also possible to retain only one of the left half shaft 6 or the right half shaft 7 as the input shaft, and the power input end of the other shaft is shortened to hide the inside of the gear box 10.

Deformed example 2

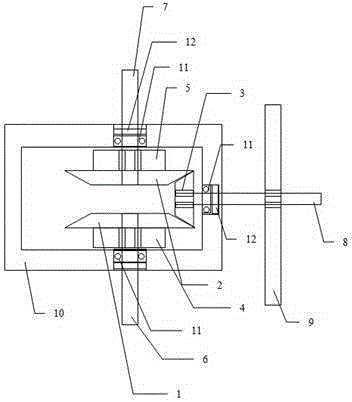

[0018] In the above-mentioned embodiment, an example in which the left half shaft 6 and the right half shaft 7 are integrated, and the power input can be unilaterally input or both left and right ends can be input simultaneously. However, the present invention does not limit this structure. For example, attach image 3 As shown, the intermediate connection between the left half shaft 6 and the right half shaft 7 can be disconnected from each other.

Deformed example 3

[0020] In the above-mentioned embodiment, an example in which the left half shaft 6 and the right half shaft 7 are integrated, and the power input can be unilaterally input or both left and right ends can be input simultaneously. However, the present invention does not limit this structure. For example, attach Figure 4 As shown, the intermediate connection between the left half shaft 6 and the right half shaft 7 can be disconnected. The first overrunning clutch 4 is installed on the left end of the left half shaft 6 and the second overrunning clutch 5 is installed on the right end of the right half shaft 7. When the swing rotation power is input to the first overrunning clutch 4 and the second overrunning clutch 5 at the same time, the first overrunning clutch 4 captures the forward rotation power and transmits it to the left half shaft 6 and the first gear 1 and the third gear 3 for one-way rotation , The second overrunning clutch 5 captures the reverse rotation power and tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com