A detection tool for large-diameter external conical surface

A technology for detecting tooling and external cones, applied in the direction of mechanical diameter measurement, measuring devices, angle/taper measurement, etc., can solve the problems of large impact on machine tool accuracy, complicated measurement process, and low efficiency, so as to improve detection efficiency and ensure accuracy Sexuality, rapid detection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

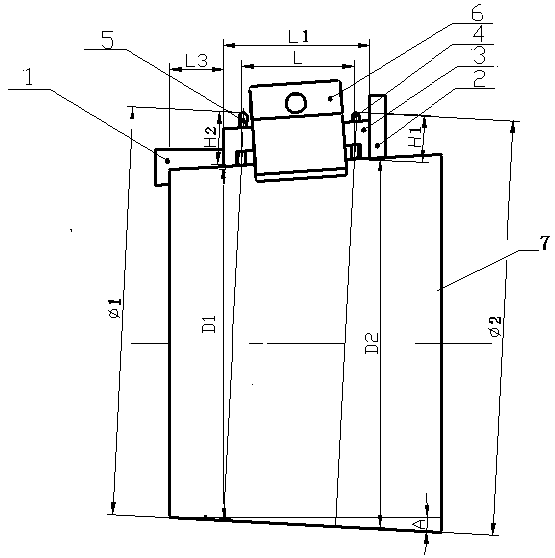

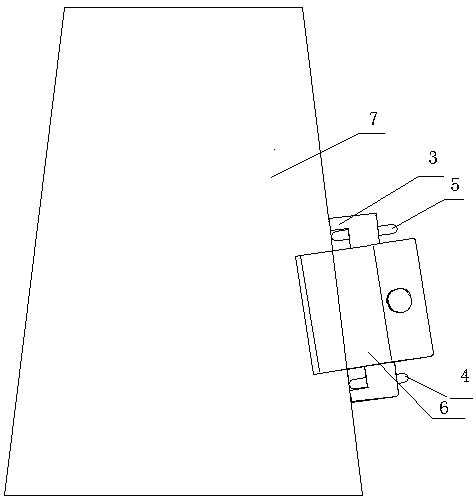

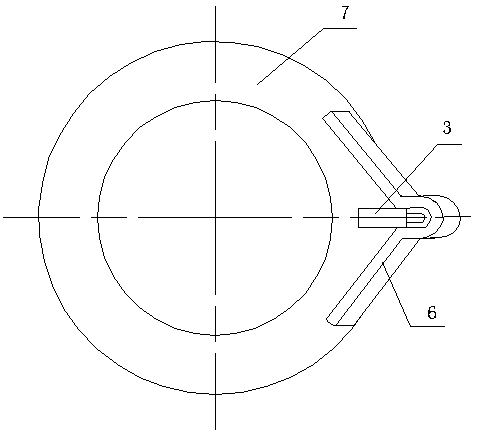

[0019] Such as figure 1 , 2 , 3, a detection tool for a large-diameter outer conical surface according to the present invention includes a fixed clamping plate 1, a fixed magnet block 2, a support block 3, a reference measurement column one 4, a reference measurement column two 5, and a base 6 ; The base 6 includes a hollow U-shaped middle part, two rectangular plates connected to the two ends of the middle part respectively, a V-shaped structure is formed between the rectangular plates, and the base 6 is fixed on the round table workpiece by two rectangular plates Between the circular surfaces whose diameter needs to be measured on the side; the support block 3 is in a concave structure and is located inside the V-shaped structu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com