A system and method for time-domain conversion of internal-combustion engine cylinder pressure signal to angle domain

A technology of in-cylinder pressure and rotation angle, which is applied in the system field of internal combustion engine cylinder pressure signal time domain and rotation angle domain, can solve problems such as encoder installation difficulties, test system error sampling, encoder output signal loss, etc. The device is difficult to fix, the installation requirements are low, and the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention is described in detail below in conjunction with accompanying drawing:

[0037] The present invention proposes a new method for testing the in-cylinder pressure signal in view of the problems of inconvenient installation of the encoder, loss of the encoder signal or being affected by interference and easy sampling abnormality in the current in-cylinder pressure signal testing method. The method has the advantages of convenient sensor installation, reliable operation, etc., can meet the needs of internal combustion engine research and development and production unit cylinder pressure signal test and analysis, and has broad application prospects.

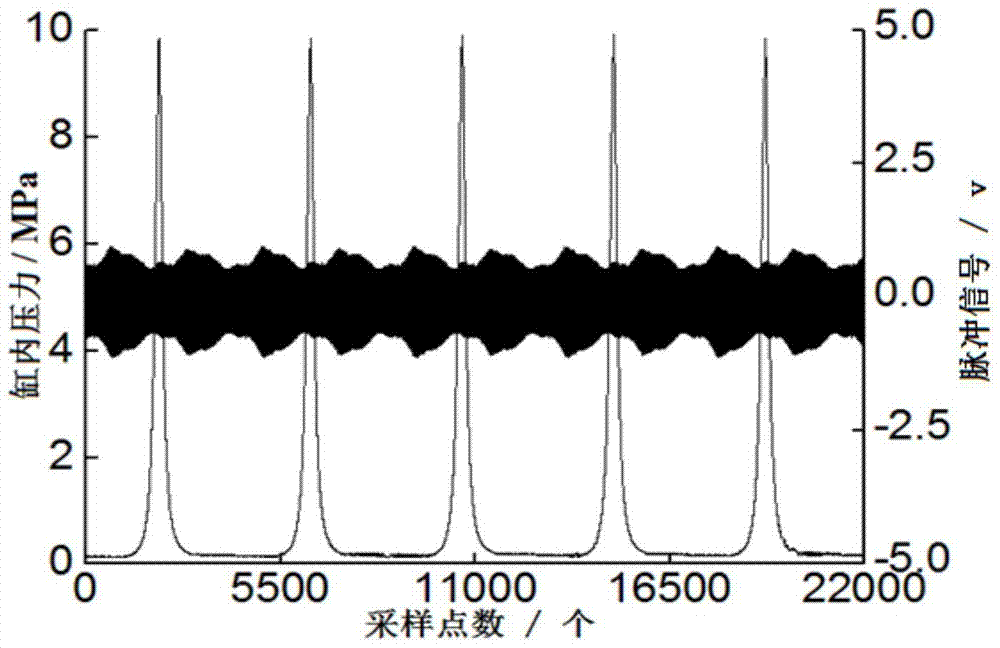

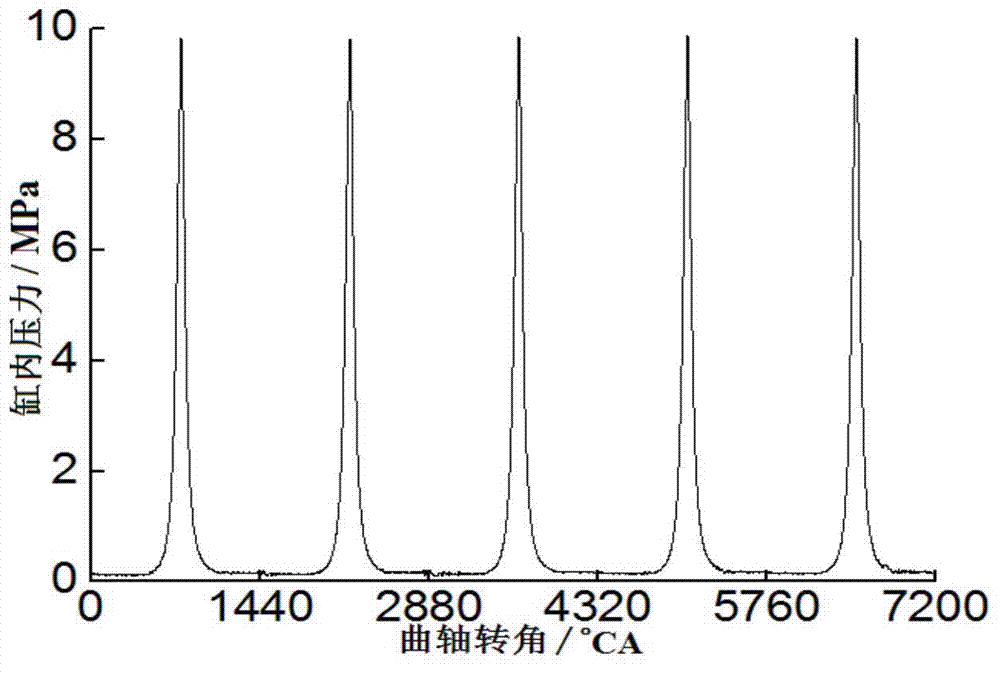

[0038] The invention proposes a test method and system suitable for collecting pressure signals in cylinders, including two parts: a hardware system and a test analysis method.

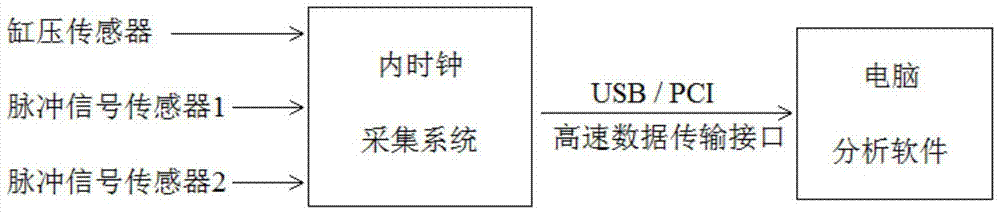

[0039] 1. Hardware system introduction: The hardware system includes two parts: the sensor and the internal clock data acquisiti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com