Improved method for carrying out rock shearing test by using rock triaxial compression apparatus

A triaxial compression and shear test technology, which is applied in the direction of applying stable shear force to test the strength of materials, can solve the problems of large dispersion of test results, achieve fine data collection, reduce system errors, and improve cost performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] In order to further describe the present invention, an improved method for performing rock shear tests using a rock triaxial compression instrument of the present invention will be further described in detail below in conjunction with the accompanying drawings.

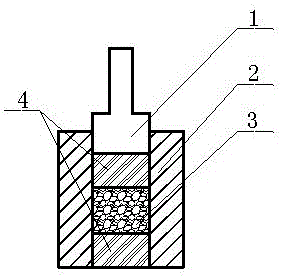

[0052] Depend on figure 1 The shown existing rock triaxial compression test figure finds out that the first cylindrical backing plate 4, the rock sample 3, and the second cylindrical backing plate 4 are put into the pressure chamber 2 from bottom to top, and the The bottom of the jack head 1 is placed in the pressure chamber 2 above the second cylindrical backing plate 4 to apply pressure.

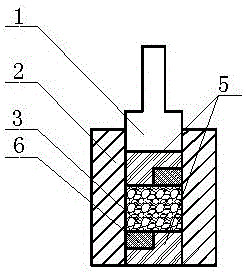

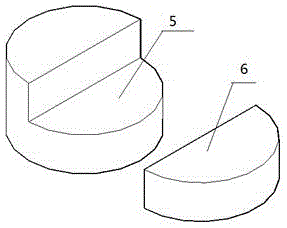

[0053] Depend on figure 2 The triaxial shear test figure under the first kind of improved combination mold of the present invention shown and combine image 3 , Figure 4 It can be seen that a kind of improved method of carrying out the rock shear test by a kind of rock triaxial compression instrument of the present inv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com