Computer vision-based bamboo strip surface defect detection method

A computer vision and defect detection technology, applied in the field of image processing, can solve problems such as weak anti-noise ability, difficult to popularize and apply, and insufficient stability, and achieve the effect of strong anti-noise, simple and practical algorithm, and easy program implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

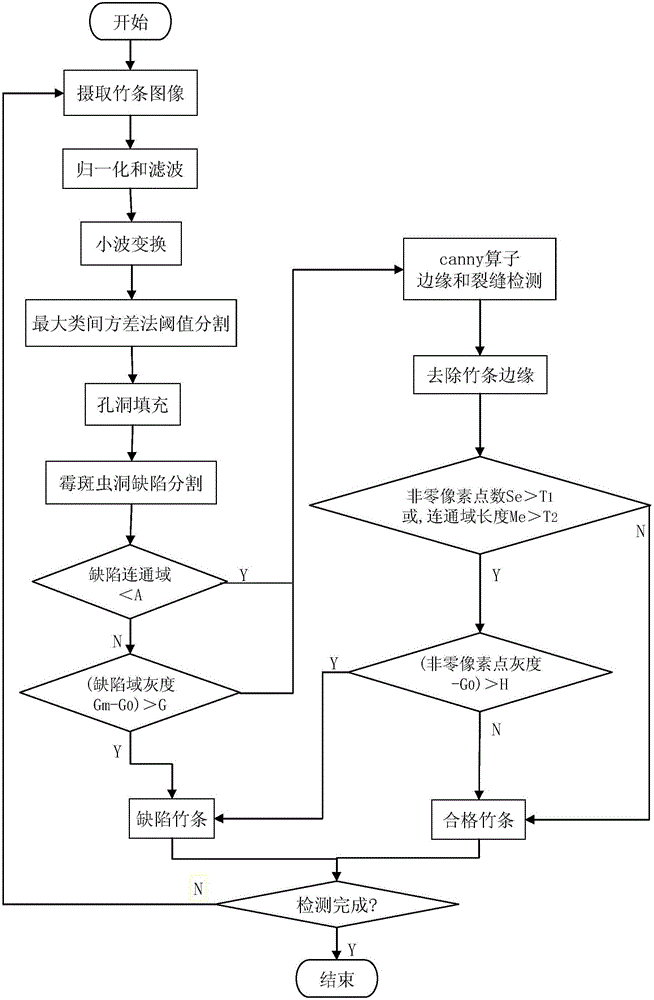

[0056] The main steps are as follows:

[0057] Ⅰ. Capture the image of the bamboo strips

[0058] Take the grayscale image f of the bamboo strip surface with black flannelette as the background, such as figure 2 As shown, there is a dark dot in the middle of the bamboo image;

[0059] Ⅱ. Normalization

[0060] The image f is normalized by the gamma correction method to obtain the image fg;

[0061] Ⅲ. Filtering

[0062] Perform median filtering and Gaussian filtering on image fg to obtain image f 1 ;

[0063] Ⅳ. Wavelet transform processing

[0064] Using sym4 wavelet to image f 1 Perform four-level wavelet transform to obtain image f 2 ,Such as image 3 As shown, the dark dots in the middle of the bamboo image are clearer;

[0065] Ⅴ. Threshold segmentation of the maximum between-class variance method

[0066] Using the maximum between-class variance method (OTSU) to image f 2 The foreground and background are thresholded, the segmentation threshold is t, and the...

Embodiment 2

[0076] The main steps are as follows:

[0077] Ⅰ. Capture the image of the bamboo strips

[0078] Identical with embodiment 1 step Ⅰ, the grayscale image f of the surface of the bamboo strips obtained is as follows Figure 7 As shown in , there is a light line on the edge of the bamboo strip image;

[0079] Steps II-IV are the same as in Example 1, and the image f is obtained 2 ,Such as Figure 8 As shown in , there is a light line on the edge of the bamboo strip image;

[0080] Step Ⅴ~same as embodiment 1, obtain image f 5 , this example image f 5 The area of the defect connected domain displayed in is smaller than the defect domain area threshold A; it is judged that the bamboo strip has no mold spots or wormhole defects; enter step Ⅷ;

[0081] Ⅷ. Edge and crack detection

[0082] Use the canny operator to traverse the image f 2 , get the image f 6 ,Such as Figure 9 As shown, this image f 2 In addition to the crack defect, there is also the edge of the bamboo s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com