Aptamer-modified magnetic nano material and application thereof in separating ochratoxin A

A technology of ochratoxin and aptamer, which is applied in the field of separation of ochratoxin A, can solve the problems of large OTA error and poor accuracy, and achieve the effects of improved accuracy, good selectivity, and high immobilization capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

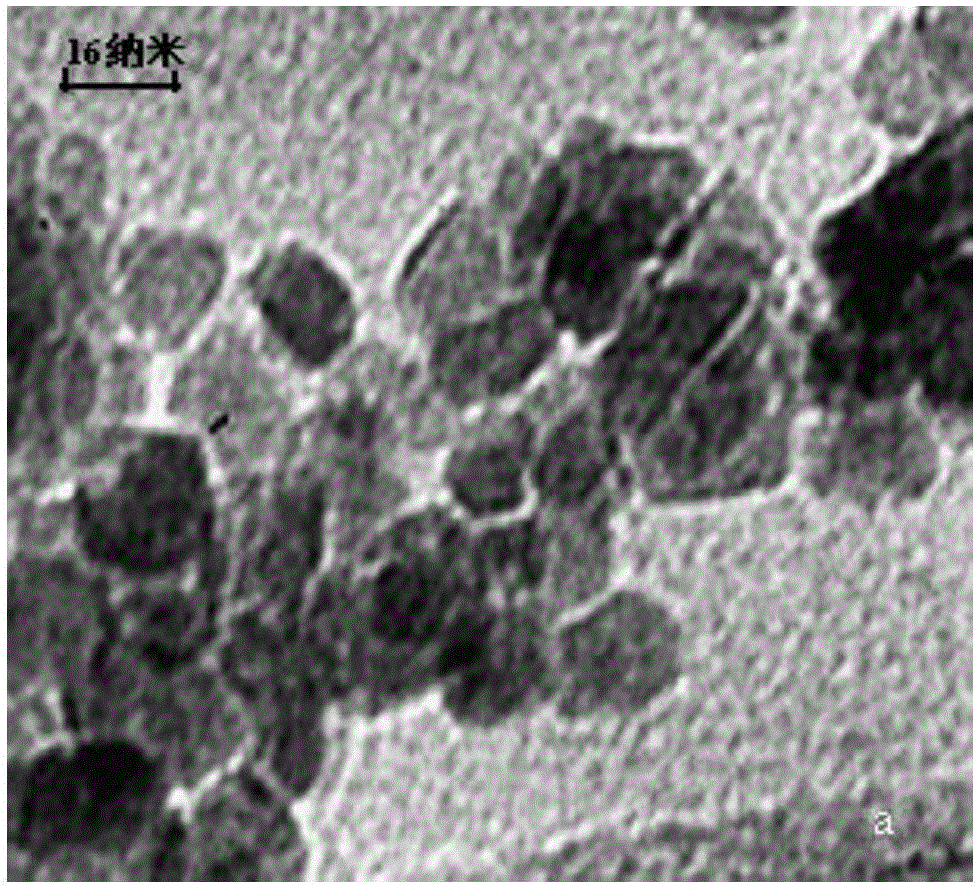

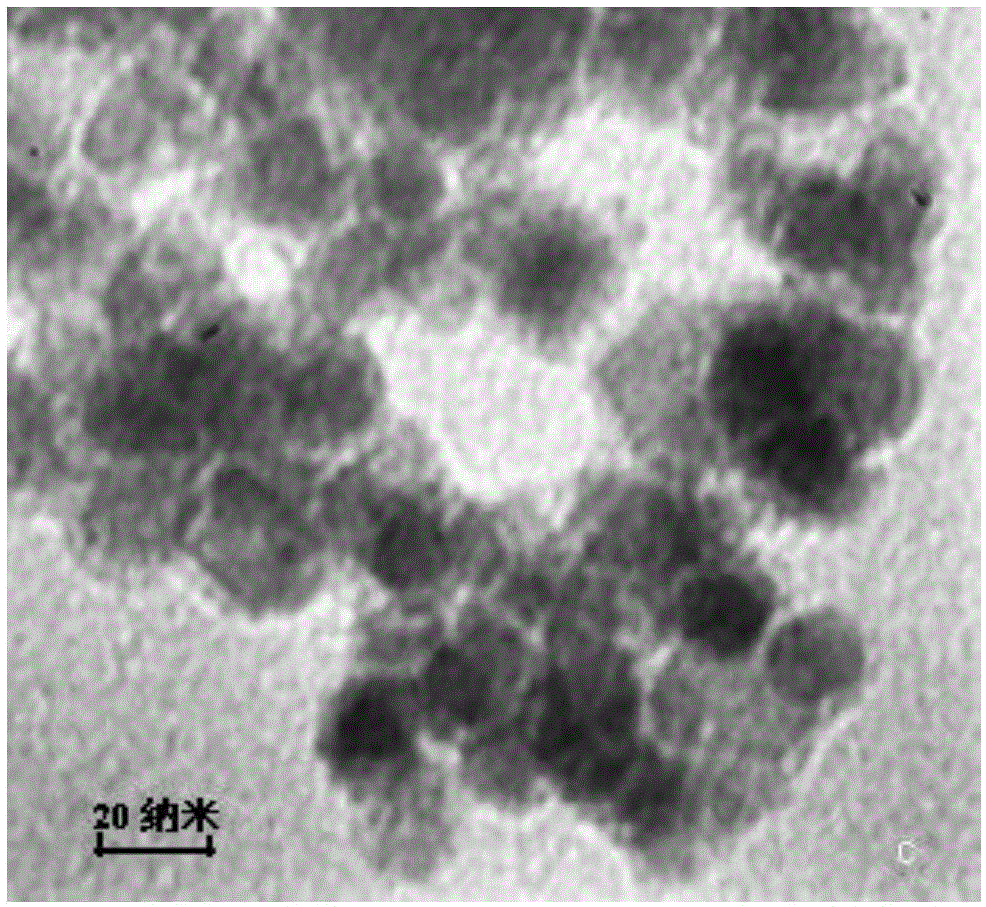

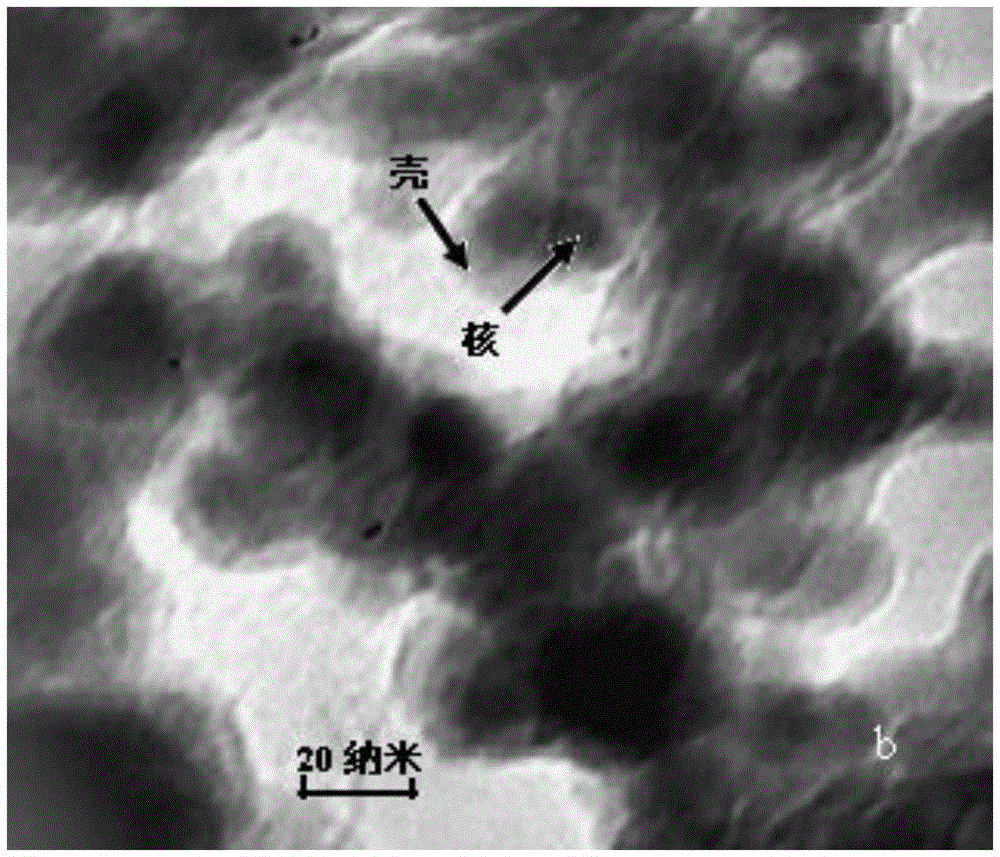

[0045] This embodiment provides an ochratoxin A aptamer-magnetic nanoparticle composite, which includes an inner core layer and an outer shell layer, wherein the inner core layer is made of paramagnetic Fe 3 O 4 It is composed of magnetic nanoparticles, and the outer shell layer includes an inner silanization layer and an aptamer modification layer on the outer side of the silanization layer.

[0046] The ochratoxin A aptamer-magnetic nanoparticle complex is prepared by the following method:

[0047] (1) Preparation of the inner core layer

[0048] 1.99gFeCl 2 ·4H 2 O and 5.41gFeCl 3 ·6H 2 O was dissolved in 160ml of 0.1mol / L hydrochloric acid solution to obtain a mixed solution. The FeCl 2 ·4H 2 O and FeCl 3 ·6H 2 The molar ratio of O is 1:2;

[0049] The mixed solution was transferred into a 250ml flask, and nitrogen was introduced. Under nitrogen protection, the mixture was stirred vigorously for 15 minutes. At 30°C, 3mol / L NaOH solution was slowly added dropwise to the mixed soluti...

Embodiment 2

[0079] This embodiment provides an ochratoxin A aptamer-magnetic nanoparticle composite, which includes an inner core layer and an outer shell layer, wherein the inner core layer is made of paramagnetic Fe 3 O 4 It is composed of magnetic nanoparticles, and the outer shell layer includes an inner silanization layer and an aptamer modification layer on the outer side of the silanization layer.

[0080] The ochratoxin A aptamer-magnetic nanoparticle complex is prepared by the following method:

[0081] (1) Preparation of the inner core layer

[0082] 1.99gFeCl 2 ·4H 2 O and 5.41gFeCl 3 ·6H 2 O was dissolved in 160ml of 0.1mol / L hydrochloric acid solution to obtain a mixed solution. The FeCl 2 ·4H 2 O and FeCl 3 ·6H 2 The molar ratio of O is 1:2;

[0083] The mixed solution was transferred into a 250ml flask, and nitrogen was introduced. Under the protection of nitrogen, the mixture was stirred vigorously for 30 minutes. At 50°C, 5mol / L NaOH solution was slowly added dropwise to the mixed...

Embodiment 3

[0098] This embodiment provides an ochratoxin A aptamer-magnetic nanoparticle composite, which includes an inner core layer and an outer shell layer, wherein the inner core layer is made of paramagnetic Fe 3 O 4 It is composed of magnetic nanoparticles, and the outer shell layer includes an inner silanization layer and an aptamer modification layer on the outer side of the silanization layer.

[0099] The ochratoxin A aptamer-magnetic nanoparticle complex is prepared by the following method:

[0100] (1) Preparation of the inner core layer

[0101] 1.99gFeCl 2 ·4H 2 O and 5.41gFeCl 3 ·6H 2 O was dissolved in 160ml of 0.1mol / L hydrochloric acid solution to obtain a mixed solution. The FeCl 2 ·4H 2 O and FeCl 3 ·6H 2 The molar ratio of O is 1:2;

[0102] The mixed solution was transferred into a 250ml flask, and nitrogen was introduced. Under nitrogen protection, the mixture was stirred vigorously for 25 min. At 40°C, 4mol / L NaOH solution was slowly added dropwise to the mixed solution a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com