A Device Structure Using Trench Field Effect to Realize Adaptive Field Stop Technology

A device structure and self-adaptive technology, applied in semiconductor devices, electrical components, circuits, etc., can solve problems such as impact, process limitations, and limited diffusion depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

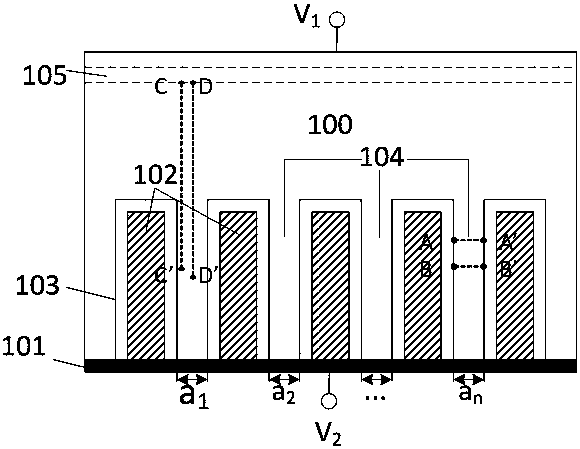

[0033] A device structure using trench field effect to realize adaptive field stop technology includes a metal conductive layer 101, a substrate 100 is arranged on one side of the metal conductive layer 101, and a plurality of grooves are arranged on the substrate 100, One side of the substrate 100 is provided with a depletion region 105, one side of the depletion region 105 is provided with a potential V1, and the metal conductive layer 101 on one side of the trench is provided with a potential V2; each trench is provided with a trench The trench conductive filling 102 is provided with an insulating layer 103 on the sidewall and bottom 1031 of the trench, and the interconnected induced charge concentration enhancement regions 104 are formed between the trenches. The widths of the induced charge concentration enhanced regions 104 are respectively a1, a2, . . . , an, wherein n represents the number of the induced charge concentration enhanced regions 104 . The interconnected in...

Embodiment 2

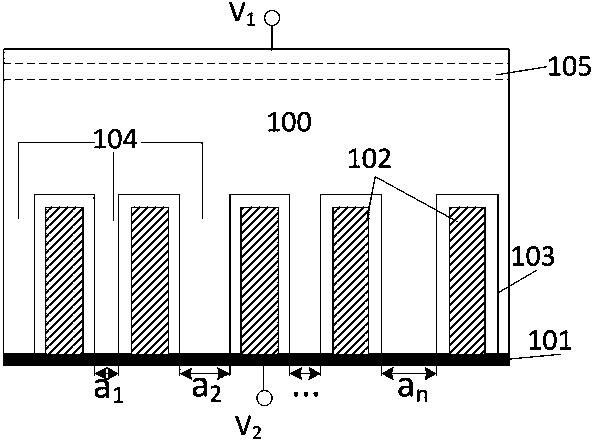

[0036] A device structure using trench field effect to realize adaptive field stop technology includes a metal conductive layer 101, a substrate 100 is arranged on one side of the metal conductive layer 101, and a plurality of grooves are arranged on the substrate 100, One side of the substrate 100 is provided with a depletion region 105, one side of the depletion region 105 is provided with a potential V1, and the metal conductive layer 101 on one side of the trench is provided with a potential V2; each trench is provided with a trench Groove conductive filling 102, an insulating layer 103 is arranged on the side walls of the trench and the bottom 1031 of the trench, and interconnected induced charge concentration enhanced regions 104 are formed between each trench, and the widths of each induced charge concentration enhanced region 104 are respectively are a1, a2, . . . , an, wherein n represents the number of induced charge concentration enhancement regions 104 .

[0037] T...

Embodiment 3

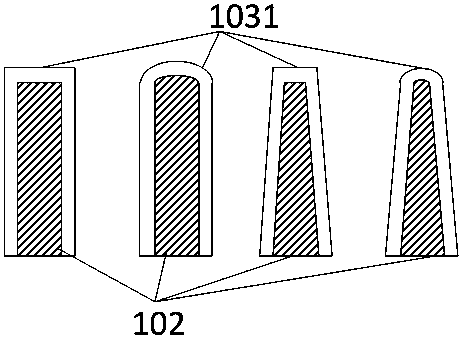

[0048] A device structure using trench field effect to realize adaptive field stop technology includes a metal conductive layer 101, a substrate 100 is arranged on one side of the metal conductive layer 101, and a plurality of grooves are arranged on the substrate 100, One side of the substrate 100 is provided with a depletion region 105, one side of the depletion region 105 is provided with a potential V1, and the metal conductive layer 101 on one side of the trench is provided with a potential V2; each trench is provided with a trench The trench conductive filler 102 is provided with an insulating layer 103 on the trench sidewall and the trench bottom 1031 , and an induced charge concentration enhancement region 104 connected to each other is formed between the trenches. The widths of the induced charge concentration enhanced regions 104 are respectively a1, a2, . . . , an, wherein n represents the number of the induced charge concentration enhanced regions 104 .

[0049] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com