Power line carrier based distributed control system for magnetron power sources

A distributed control and power carrier technology, which is applied in the fields of electrical components, energy industry, circuit devices, etc., can solve the problems of expensive equipment, complicated wiring, and simple human interface of the PLC system, achieving small operation and maintenance, good confidentiality, The effect of stable system operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

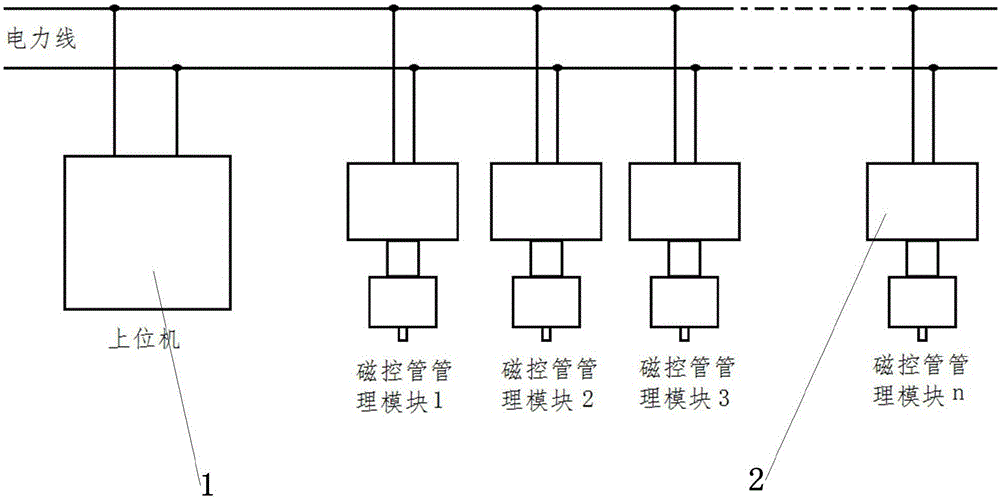

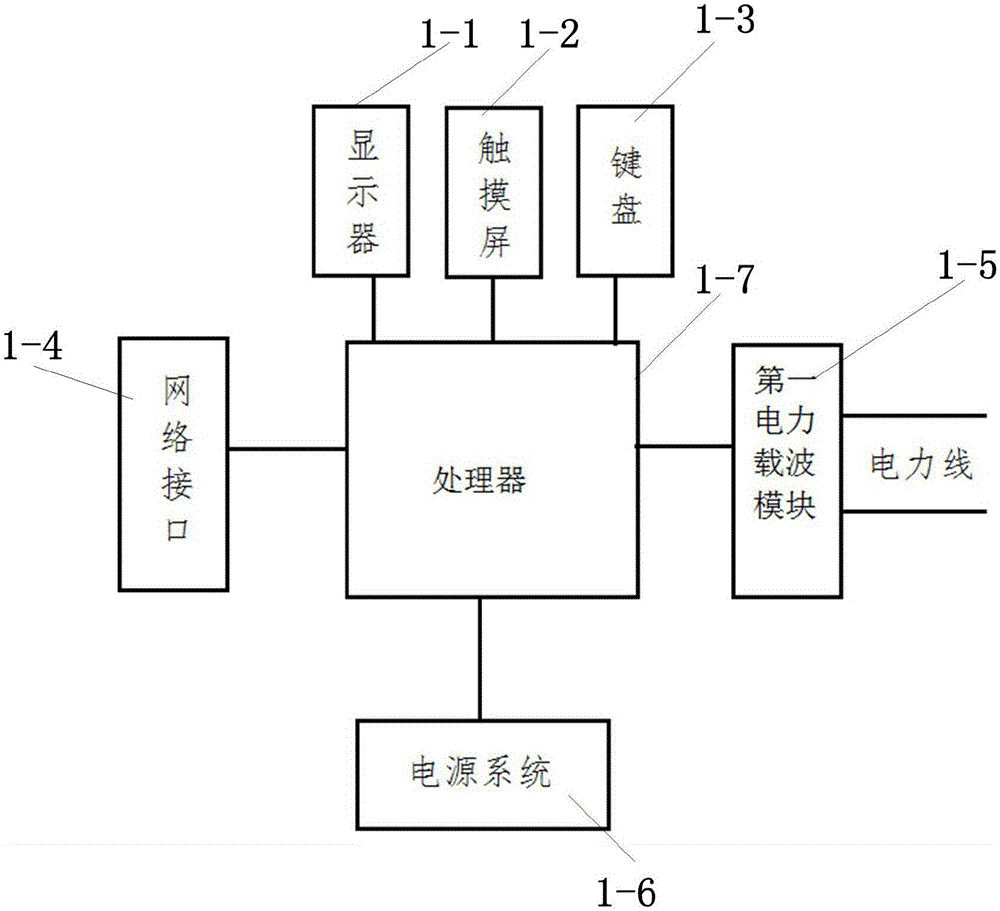

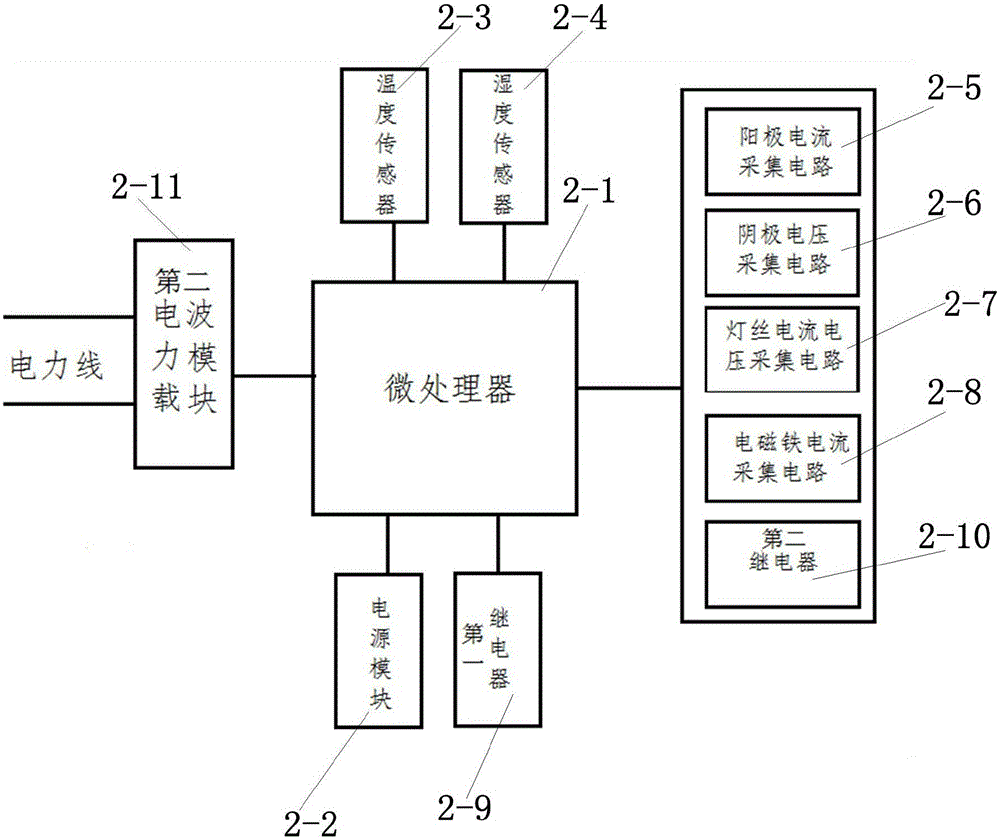

[0024] The invention consists of a host computer and a plurality of magnetron management modules, wherein the hardware of the host computer includes a microprocessor and a power carrier module, and the host computer can monitor the working status of each magnetron power supply and perform remote control. The magnetron management module is composed of a microprocessor and a power carrier module, plugged into the magnetron power supply circuit board, responsible for monitoring and collecting the temperature, anode current, cathode voltage, filament voltage, filament current, electromagnetic Parameters such as iron current. I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com