Oil internal circulation cooling motor

A technology for cooling motors and internal circulation, which is applied in the direction of motors, cooling/ventilation devices, electromechanical devices, etc. It can solve the problems of large volume, complicated process, and unsolved rotor heat dissipation problems of the rotor, and achieve good cooling effect, good effect, and excellent performance. The effect of cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further elaborated below in conjunction with the accompanying drawings and embodiments.

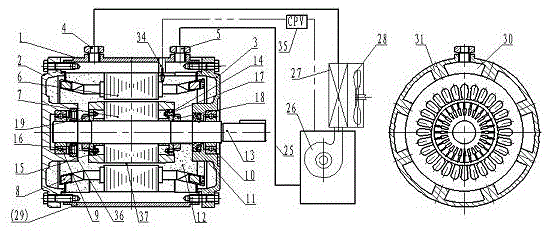

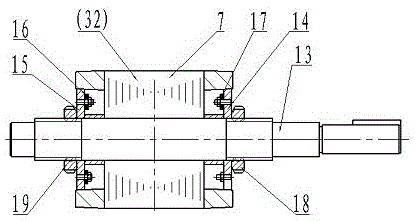

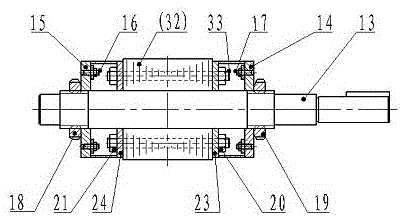

[0010] refer to figure 1 , 2 , 3. The working principle and structural diagram of this embodiment, including the oil circulation cooling closed motor 29, the cooling oil delivery pump assembly 26, the cooling oil delivery pipe 25, the cooling oil delivery pipe 25 and the cooling oil delivery pump and the closed type motor respectively. The motor oil outlet 5 is connected, the other outlet of the cooling oil delivery variable frequency pump assembly 26 is connected to the inlet of the cooling oil heat exchanger 27, and the other outlet of the cooling oil heat exchanger 27 passes through the oil delivery pipe 25 and the closed motor 29 The oil inlet 4 of the closed motor is connected to the outer diameter of the stator 6 and the casing 1 is supported by ribs 31. The stator and the interlayer space 30 of the casing 1 are cooling oil passages; the rotor o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com