Device for belt finishing workpieces

A technology for finishing and workpiece, applied in the field of belt-type finishing workpiece devices, can solve the problems of uneven distribution and low pressing force, and achieve the effect of preventing deformation and increasing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

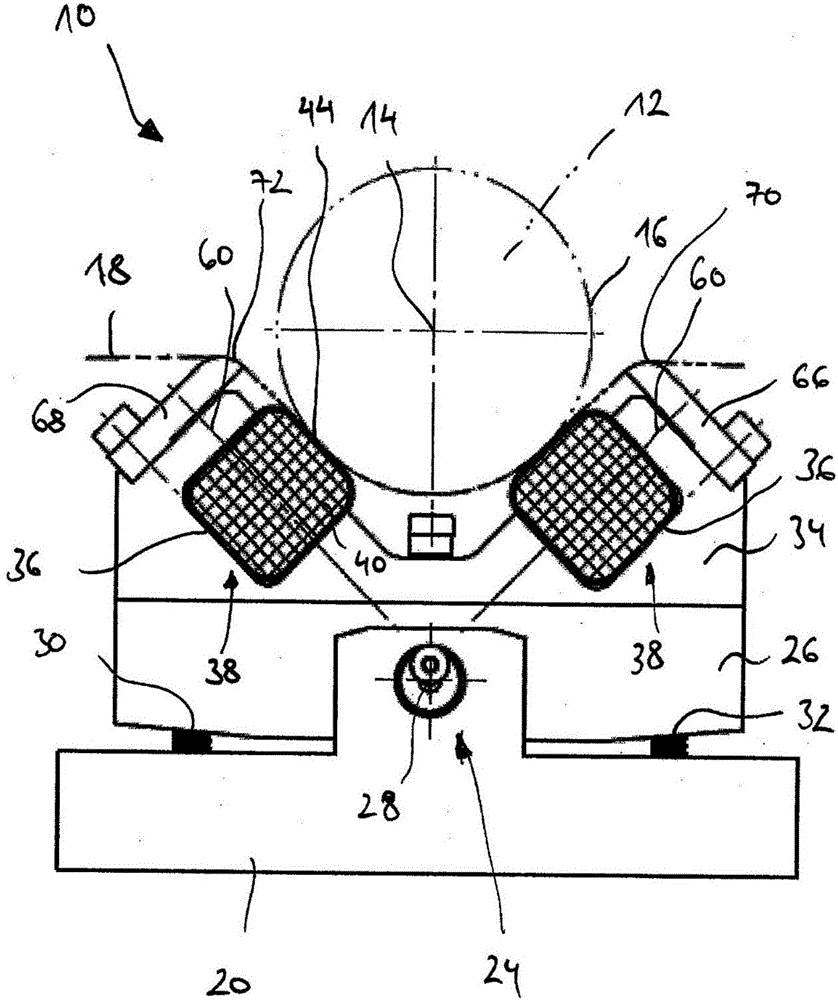

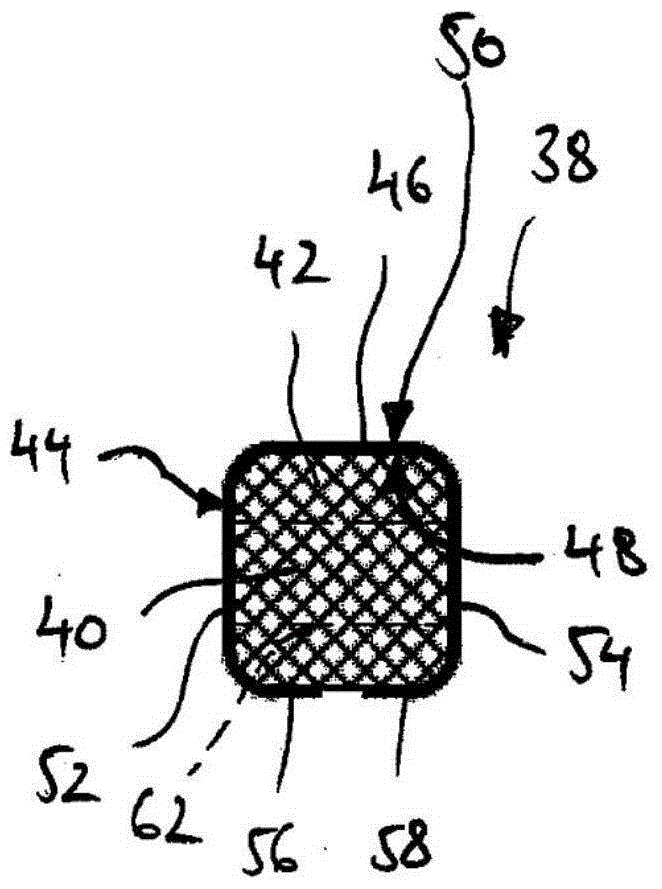

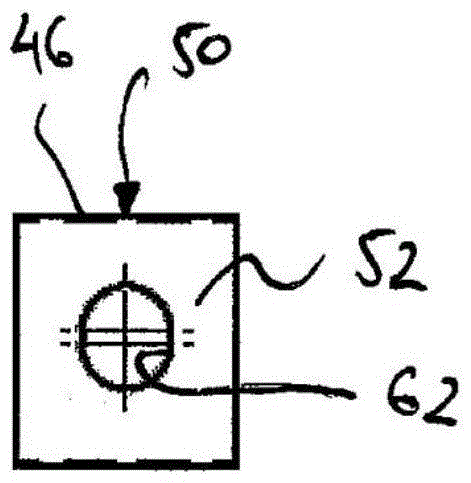

[0037] An embodiment of the device, indicated generally at 10 , is used for belt finishing, such as a crankshaft workpiece 12 . The workpiece 12 has a workpiece axis 14 and a workpiece surface 16 to be finished. For machining the workpiece surface 16 , a finishing belt 18 is provided which rests against the workpiece surface 16 along a part of its circumference. The workpiece surface 16 is, for example, a journal of a crankshaft.

[0038] During finishing machining of the workpiece 12 , the workpiece is driven by known and therefore not shown individual drives. The rotary drive moves the workpiece 12 in rotation about the workpiece axis 14 . The pivot drive moves the workpiece 12 in a pivoting motion parallel to the workpiece axis 14 in opposite directions. Through a combination of rotational and oscillating movements, the abrasive contact of the finishing belt 18 with the front side of the finishing belt with the workpiece surface 16 produces the properties of the finishin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com