Hydraulic water-filled constant-temperature adjustable posture mat

A body position pad, adjustable technology, applied in the field of body position pads, can solve the problems of wasting manpower, not being able to adjust at one time, and increasing the chance of contamination in the operation area, so as to save manpower and cost, reduce postoperative complications, and avoid cross-infection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The specific implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific examples.

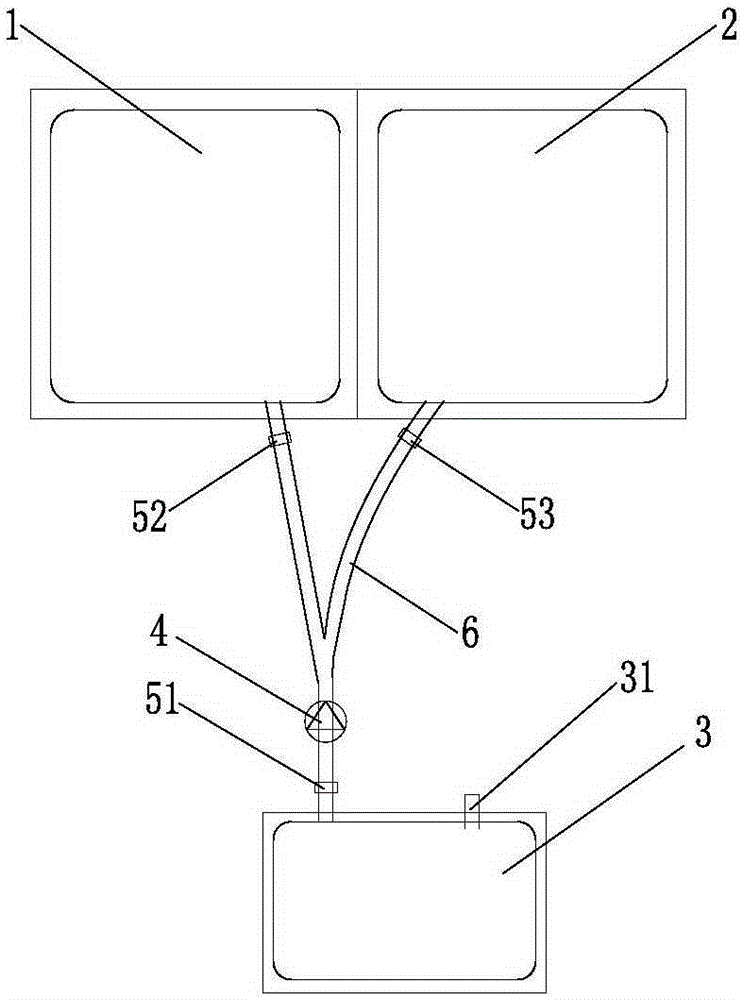

[0014] Such as figure 1 As shown, the hydraulic water-filled constant temperature adjustable body position cushion includes a left body position cushion 1, a right body position cushion 2, a storage heating bag 3, a water pump 4, a flow regulating valve I51, a flow regulating valve II52 and a flow regulating valve III53. The body position pad and the right body position pad are mutually independent and sealed structures. The left body position pad and the right body position pad are connected to the storage heating bag through the water-filled pipe 6 provided with a three-way bifurcated type. The storage heating bag is provided with a water inlet. 31. The water pump is arranged on the water filling pipe close to the storage heating bag, and is used to pump the heated water into the left and right bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com