Sarcandra glabra functional composition extraction method and fiber product

A coral and functional technology, applied in the field of fiber products, can solve the problems of low production capacity, inconvenient operation, long extraction time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

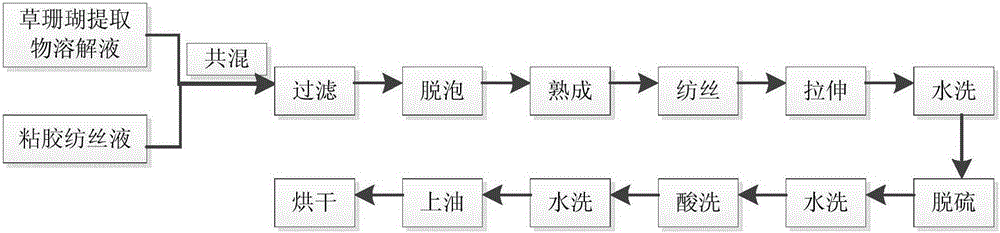

Method used

Image

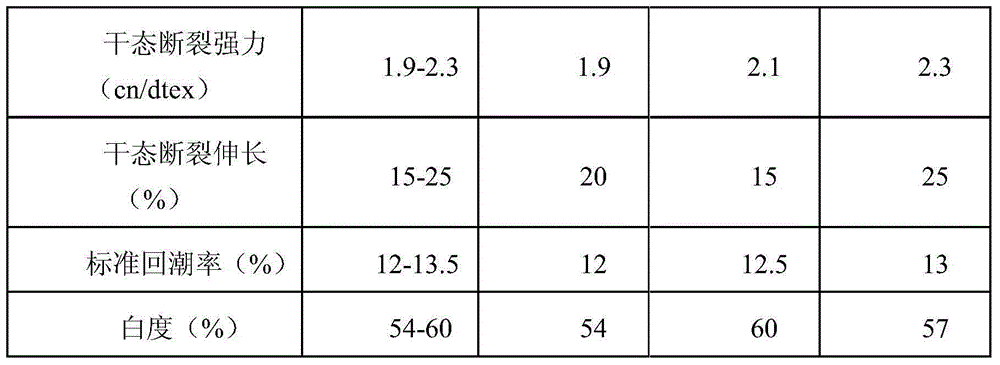

Examples

Embodiment 1

[0042] The present embodiment is the extraction of the active ingredients of the grass coral function, and specifically adopts the following steps:

[0043] Screened grass coral raw material is dried, pulverized and crossed 40 mesh sieves to make grass coral powder;

[0044] Weigh 10.0g grass coral powder and place it in a glass vessel, add 100ml of absolute ethanol;

[0045] Put it into an ultrasonic-microwave system extractor to extract and obtain the extract. The microwave power is selected as 300W, the frequency is 2450MHz, the extraction time is set as 45min, the extraction temperature is 40°C, the ultrasonic power is 50W, and the frequency is 40KHz;

[0046] Suction filter the extract, and then distill under reduced pressure, the ethanol distilled under reduced pressure can be recovered, and dried after the reduced pressure distillation, and the functional active ingredient of grass coral is obtained.

[0047] Grass coral effective functional components extraction test ...

Embodiment 2

[0050] The present embodiment is the extraction of the active ingredient of the grass coral function, and specifically adopts the following steps:

[0051] Screened grass coral raw material is dried, pulverized and crossed 40 mesh sieves to make grass coral powder;

[0052] Weigh 10.0g grass coral powder and place it in a glass vessel, add 70ml of absolute ethanol;

[0053] Put it into an ultrasonic-microwave system extractor to extract the extract, the microwave power is 250W, the microwave frequency is 2400MHz, the extraction time is set to 50min, the extraction temperature is 30°C, the ultrasonic power is 40W, and the ultrasonic frequency is 30KHz;

[0054] Suction filter the extract, and then distill under reduced pressure, the ethanol distilled under reduced pressure can be recovered, and dried after the reduced pressure distillation, and the functional active ingredient of grass coral is obtained.

[0055] Grass coral effective functional components extraction test comp...

Embodiment 3

[0058] The present embodiment is the extraction of the active ingredients of the grass coral function, and specifically adopts the following steps:

[0059] Screened grass coral raw material is dried, pulverized and crossed 40 mesh sieves to make grass coral powder;

[0060] Weigh 10.0g grass coral powder and place it in a glass vessel, add 120ml of absolute ethanol;

[0061] Put it into an ultrasonic-microwave system extractor to extract and obtain the extract. The microwave power is 350W, the frequency is 2500MHz, the extraction time is set to 30min, the extraction temperature is 50°C, the ultrasonic power is 60W, and the frequency is 50KHz;

[0062] Suction filter the extract, and then distill under reduced pressure, the ethanol distilled under reduced pressure can be recovered, and dried after the reduced-pressure distillation to obtain the active ingredient of grass coral.

[0063] Grass coral effective functional components extraction test comparison:

[0064] Flavonoi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap