Detachable multifunctional feeding device of dry-method grinding equipment and disassembling and assembling method of detachable multifunctional feeding device

A feeding device and multi-functional technology, which is applied in the field of detachable multi-functional feeding devices, can solve the problems of unreasonable inclination angle of the feeding liner, reducing the operation rate of the equipment, and reducing the production capacity of the mill, so as to reduce the maintenance and replacement time. And manpower and material resources, reduce cost input, increase the effect of output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

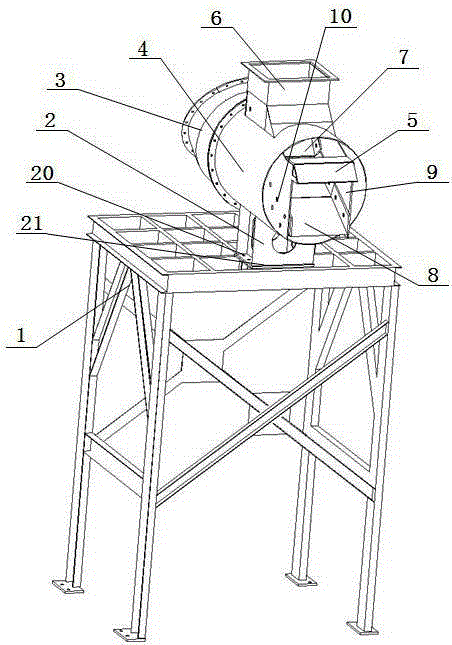

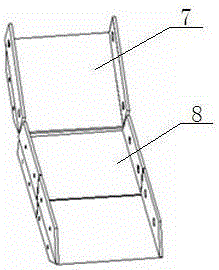

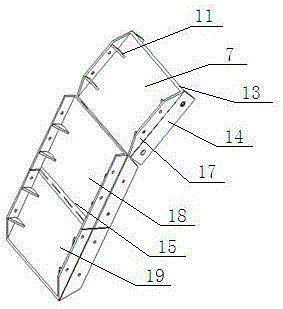

[0037] As shown in the figure, the detachable multifunctional feeding device of the dry grinding equipment is provided with a horizontal feeding chute 4, one end of the feeding chute 4 is connected to a return pipe 3, and the other end extends into the In the grinding bin 12 of the dry grinding equipment, the upper part of the feed chute 4 is provided with a feed inlet 6, and the inside of the feed chute 4 is provided with a combined hopper I7 and a combined hopper that are connected together and have different slopes. Ⅱ8 is used to accept the material falling from the feed port 6 and transport it to the mill bin 12. There is a docking gap between the combined hopper Ⅰ7 and the combined hopper Ⅱ8 to meet the ventilation requirements. The butt gap is 15~ 25mm, it can be designed as 20mm to prevent material leakage. The gap should not be too large or too small. If the gap is too large, the material will enter the feeding chute along this gap to form return material.

[0038] Bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com