Cutting device for plastic bottle

A technology of cutting device and plastic bottle, applied in metal processing and other directions, can solve the problems of poor cutting efficiency and poor cutting quality, and achieve the effect of reducing collection, good clamping effect and good use effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

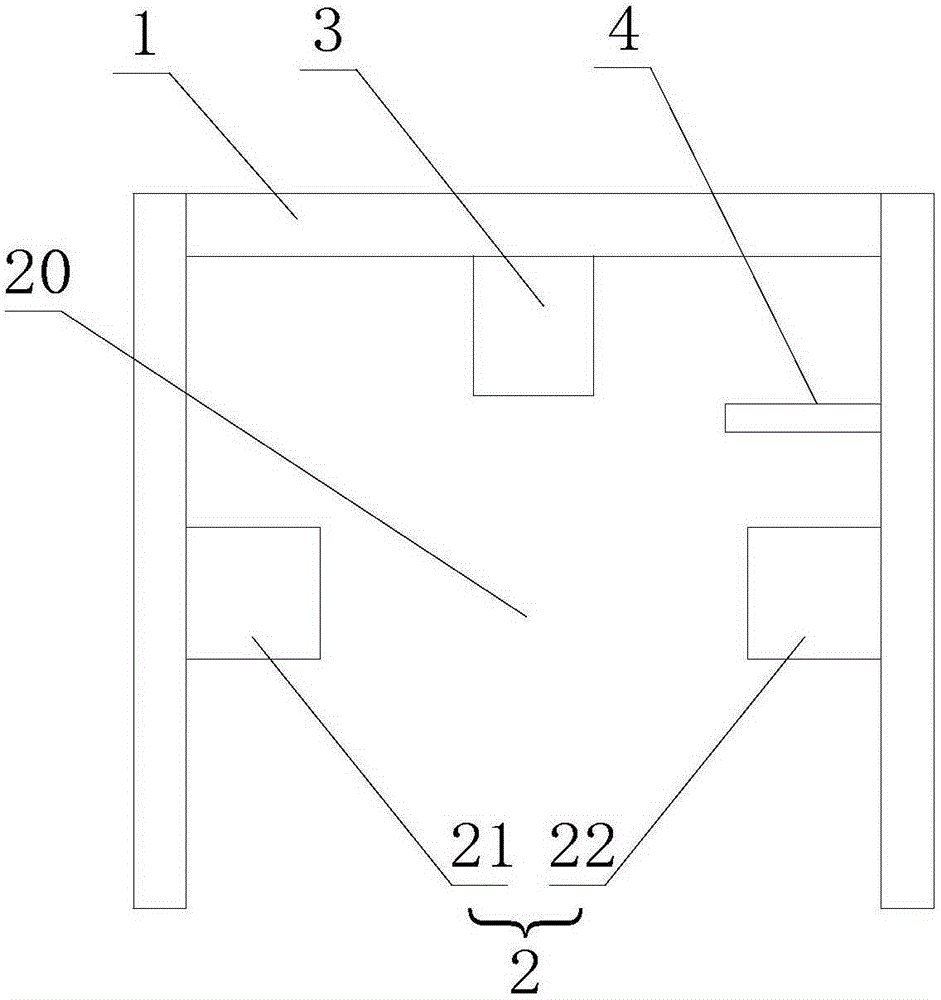

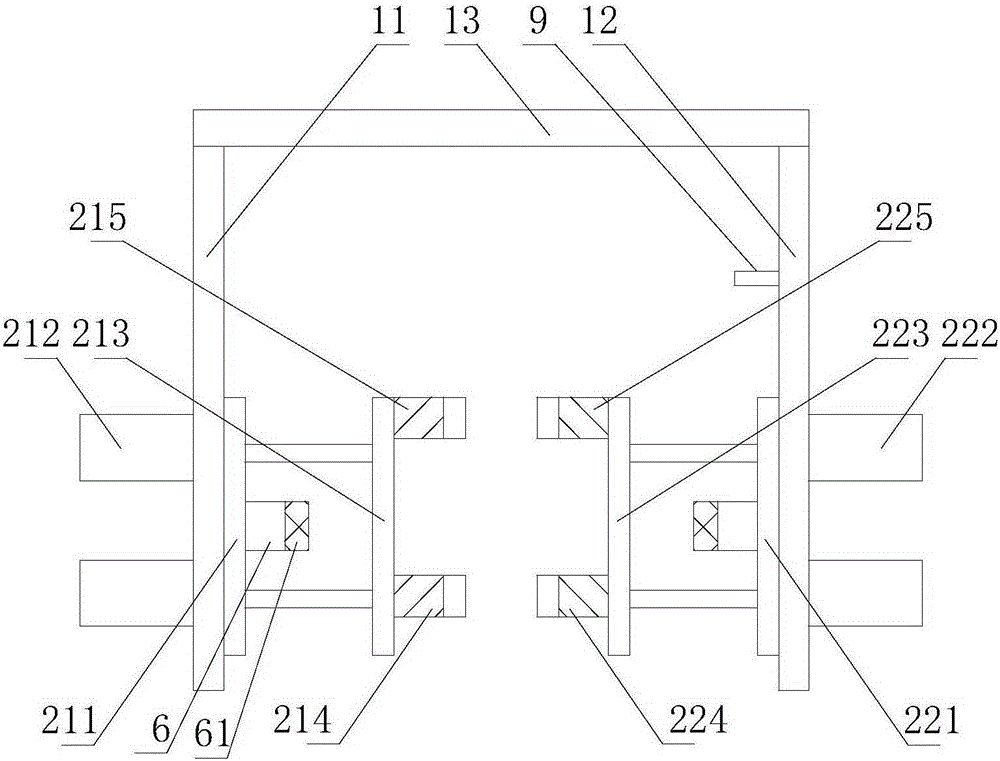

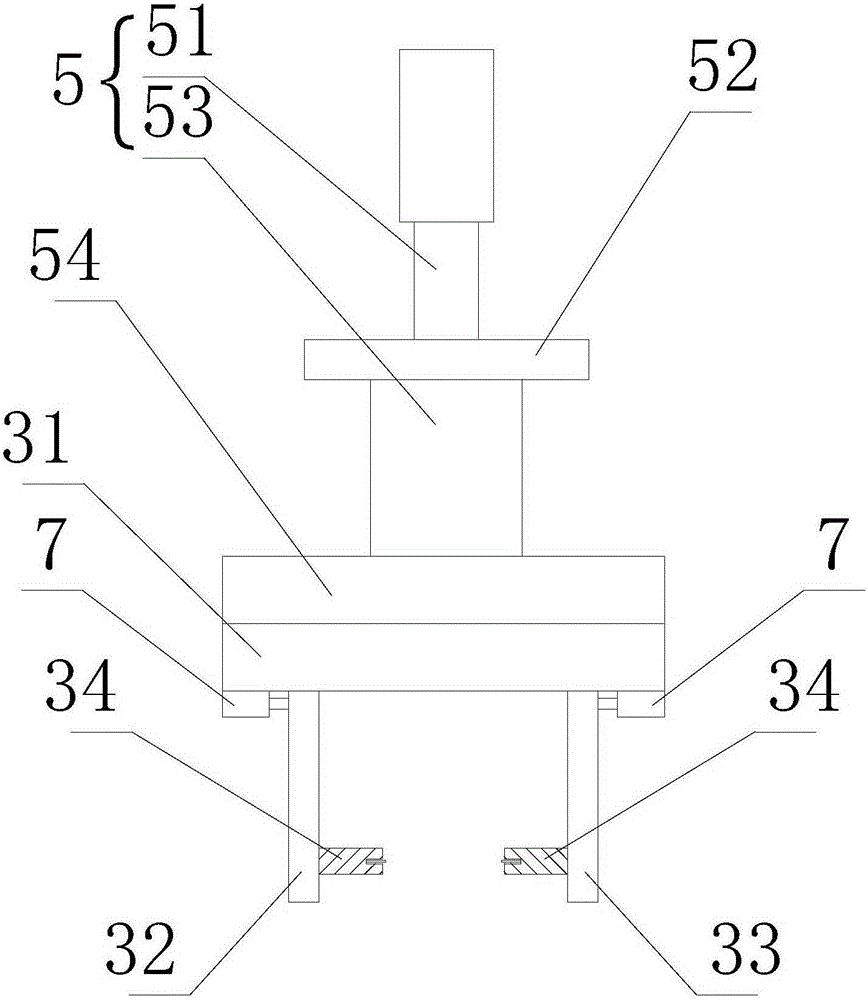

[0023] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 As shown, the plastic bottle cutting device includes a base 1, on which a clamping assembly 2 for clamping the plastic bottle is provided, and a cutting assembly 3 is provided on the base 1 above the clamping assembly 2, and a cutting assembly 3 is provided on the base 1 There is a blowing assembly 4 that blows out the cut bottle mouth waste; the clamping assembly 2 includes a first clamping part 21 and a second clamping part 22 arranged on the base 1, the first clamping part 21 and the second clamping part A clamping hole 20 is formed between the two clamping parts 22; the cutting assembly 3 includes a connecting plate 31 arranged on the base 1, a first vertical plate 32 and a second vertical plate 33, the connecting plate 31 is fixedly connected on the base, The first vertical plate 32 and the second vertical plate 33 are all movably connected on the connecting plate 31, the first vertica...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap