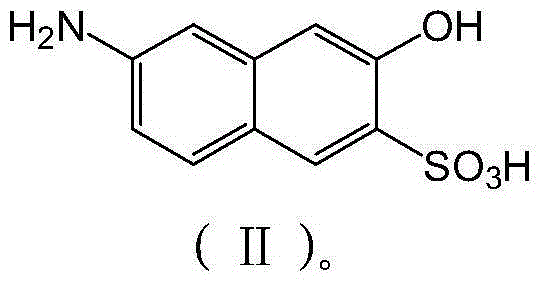

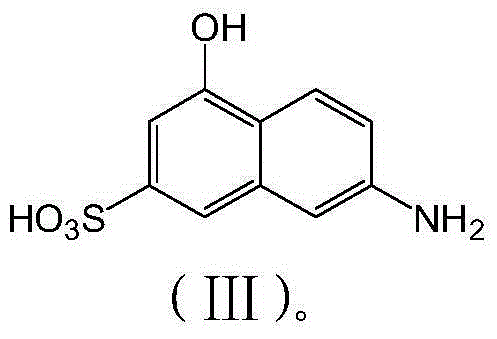

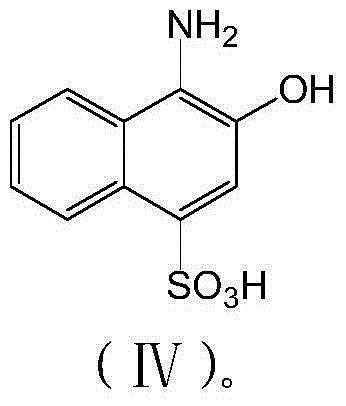

Treatment method for naphthalene-derivative-containing wastewater

A treatment method and derivative technology, which can be used in water/sewage multi-stage treatment, oxidized water/sewage treatment, water/sludge/sewage treatment, etc. The effect of reducing COD value and being easy to promote and apply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] H acid isolation mother liquor wastewater (hereinafter referred to as H acid wastewater), black, COD=26030mg / L, pH=2.

[0048] (1) Wet oxidation: adjust the H acid waste water to pH=7, put it into a wet oxidation kettle after filtration, raise the temperature to 250°C and pressure 6MPa, pass air into it for oxidation for 2 hours, then cool down, and the air flow rate is 40L / h.

[0049] It was measured that the kettle wastewater was orange-yellow, pH=4.5, COD=1883mg / L, NH 3 - N = 164.2 mg / L.

[0050] (2) Adsorption: adjust the waste water from step (1) to neutrality (pH=7), add activated carbon with a mass fraction of 0.1% (based on the quality of the waste water after pH adjustment), stir and adsorb for 0.5h and then filter , the obtained filtrate is almost colorless and transparent, COD=150mg / L, salt content 4%.

[0051](3) Concentrated crystallization: the filtrate is treated by electrodialysis (tap water is used as the water in the concentrated chamber) to obtain c...

Embodiment 2

[0055] H acid wastewater, black, COD=26030mg / L, pH=2.

[0056] (1) Wet oxidation: adjust the pH of the H-acid wastewater to 8, filter it and pour it into a wet oxidation kettle, raise the temperature to 220°C and the pressure 3MPa, pass oxygen into it for 1 hour and then cool down.

[0057] It was measured that the kettle wastewater was orange-yellow, pH=4, COD=2483mg / L, NH 3 -N=145.0 mg / L.

[0058] (2) Adsorption: adding massfraction in the waste water out of the still of step (1) is 0.1% diatomite (taking the quality of the waste water out of the still as a benchmark) to absorb for 45min, filter to obtain a light yellow treatment solution, then adjust the pH to 6.0, the color turns yellow, then add mass fraction of 0.1% activated carbon (based on the quality of the waste water from the kettle) to absorb for 30min, filter to obtain a slightly yellow treatment solution (solid rate is 3.60%), and its COD=845mg / L , NH 3 - N = 80 mg / L.

[0059] (3) Concentrated crystallizatio...

Embodiment 3

[0061] H acid wastewater, black, COD=26030mg / L, pH=2.

[0062] (1) Wet oxidation: adjust the pH of the H-acid wastewater to 8, filter it and pour it into a wet oxidation kettle, raise the temperature to 220°C and the pressure to 3MPa, and let it oxidize with air for 2 hours before cooling down.

[0063] It was measured that the kettle wastewater was orange-yellow, pH=4, COD=4983mg / L, NH 3 - N = 200 mg / L.

[0064] (2) Adsorption: adding mass fraction in the waste water out of the kettle in step (1) is 0.2% diatomite (taking the quality of the waste water out of the kettle as a benchmark) to absorb for 45min, suction filtration to obtain a light yellow treatment solution, and then adjust the pH To 7.0, the color turns yellow, and the mass fraction is 0.1% activated carbon (based on the quality of the waste water from the kettle) to absorb for 30min, and suction filtration obtains a slightly yellow treatment solution (solid rate is 3.60%), and its COD=1845mg / L.

[0065] (3) C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com