A kind of high-gloss oil-resistant styrene resin and its preparation method and application

A styrene-based resin, high-gloss technology, applied in the field of modified resins, can solve the problems not mentioned, and achieve the effect of low surface energy, high gloss, and less addition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

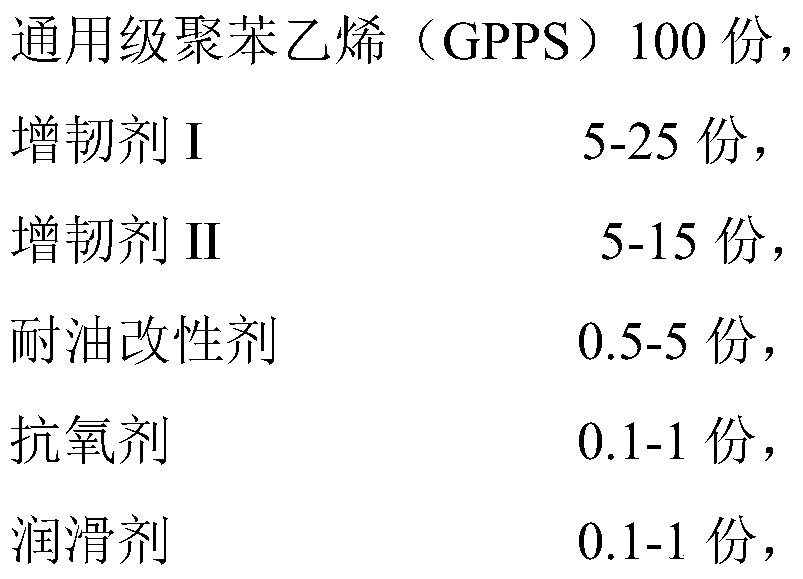

Method used

Image

Examples

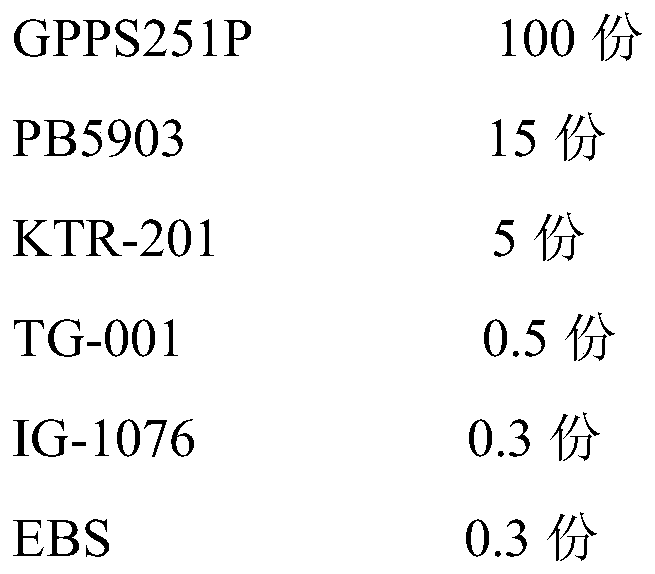

Embodiment 1

[0034] S11, take by weighing (components by weight, the same below)

[0035]

[0036] S12. Put the above raw materials weighed in step S11 into a high-speed mixer and stir for 5-30 minutes, then discharge to obtain a mixture;

[0037] S13. The mixture obtained in step S12 is extruded and granulated through a twin-screw extruder, wherein the temperature of the twin-screw extruder is 180-260° C., and the screw speed is 180-600 rpm. The product is obtained by conveying, melting, shearing, extrusion, cooling and granulation.

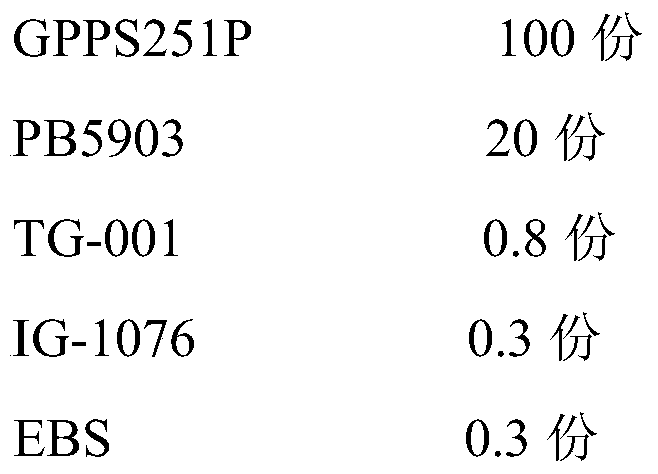

Embodiment 2

[0039] S21, weighing

[0040]

[0041] S22. Put the above raw materials weighed in step S21 into a high-speed mixer and stir for 5-30 minutes, then discharge to obtain a mixture;

[0042] S23. The mixture obtained in step S22 is extruded and granulated through a twin-screw extruder, wherein the temperature of the twin-screw extruder is 180-260° C., and the screw speed is 180-600 rpm. The product is obtained by conveying, melting, shearing, extrusion, cooling and granulation.

Embodiment 3

[0044] S31, weighing

[0045]

[0046] S32. Put the above raw materials weighed in step S31 into a high-speed mixer and stir for 5-30 minutes, then discharge to obtain a mixture;

[0047] S33. The mixture obtained in step S32 is extruded and granulated through a twin-screw extruder, wherein the temperature of the twin-screw extruder is 180-260° C., and the screw speed is 180-600 rpm. The product is obtained by conveying, melting, shearing, extrusion, cooling and granulation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com