Coating system for spacecraft exterior skins and preparation method of coating system

A technology for aircraft and outer skin, which is applied in the coating system and its preparation field for the outer skin of aircraft, and can solve the problem of poor gloss retention rate and color durability of the coating system, the influence of color rendering accuracy, and the decrease of the gloss of the coating system, etc. problems, to achieve the effects of excellent resistance to aviation media, excellent gloss and color retention, and excellent anti-aging properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] The present invention also includes a method for preparing the coating system for the outer skin of the aircraft, comprising the steps of:

[0047] S1. Preparation of water-based anti-corrosion primer:

[0048] S101. Add the formulated amount of environmentally friendly anti-corrosion pigments, fillers, wetting and dispersing agents and part of deionized water into the mixing container and mix evenly, and grind and disperse to a fineness of ≤30 μm to prepare a water-based pre-dispersed slurry; put the water-based pre-dispersed Add the slurry into the water-based epoxy emulsion, use a high-speed disperser to stir at a speed of 400-600r / min for 15-25min, then add defoamer, anti-settling agent and anti-flash rust agent in turn, use a high-speed disperser to stir at a speed of 100-300r / min After stirring at a speed of 100-300r / min for 5-10min, add the remaining deionized water, use a high-speed disperser to continue stirring at a speed of 100-300r / min for 10-15min, and filt...

Embodiment 1

[0059] Preparation of coating system T-1

[0060] 1.1 Preparation of water-based anti-corrosion primer:

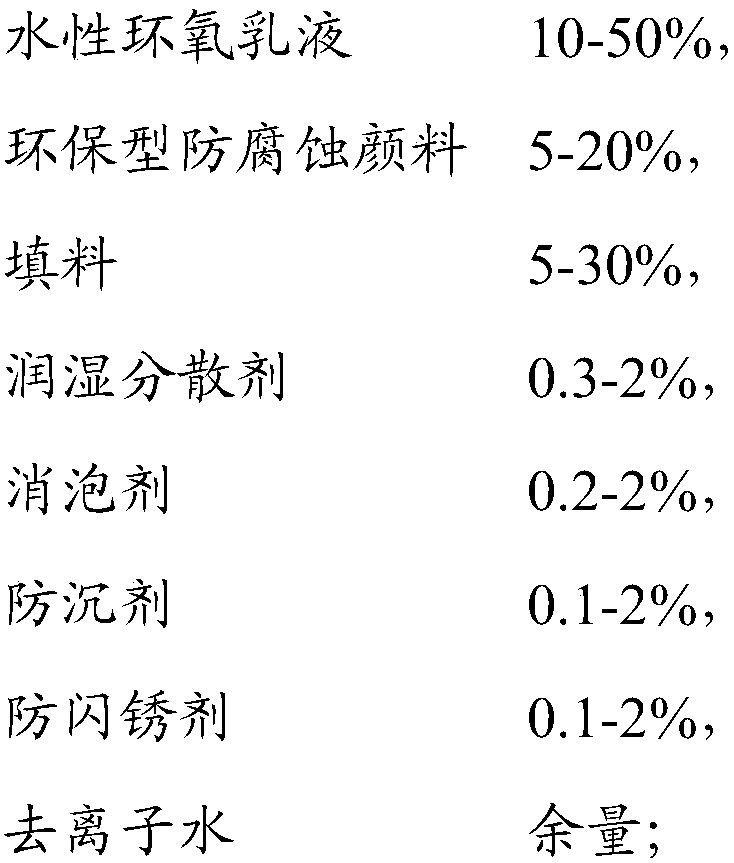

[0061] Table 1 Component A1 formula table

[0062]

[0063]

[0064] Refer to the ratio in Table 1 to prepare component A1, add environment-friendly anti-corrosion pigments, fillers, wetting and dispersing agents and part of deionized water into the mixing container and mix evenly, and grind and disperse to a fineness of ≤30 μm to obtain a water-based pre-dispersion slurry; add the water-based pre-dispersed slurry into the water-based epoxy emulsion, use a high-speed disperser to stir at a speed of 400r / min for 25min, then add defoamer, anti-settling agent and anti-flash rust agent in turn, use a high-speed disperser to 300r / min After stirring at a speed of 10 min, add the remaining deionized water, use a high-speed disperser to continue stirring at a speed of 300 r / min for 10 min, and filter with a 200-mesh silk screen to obtain component A1;

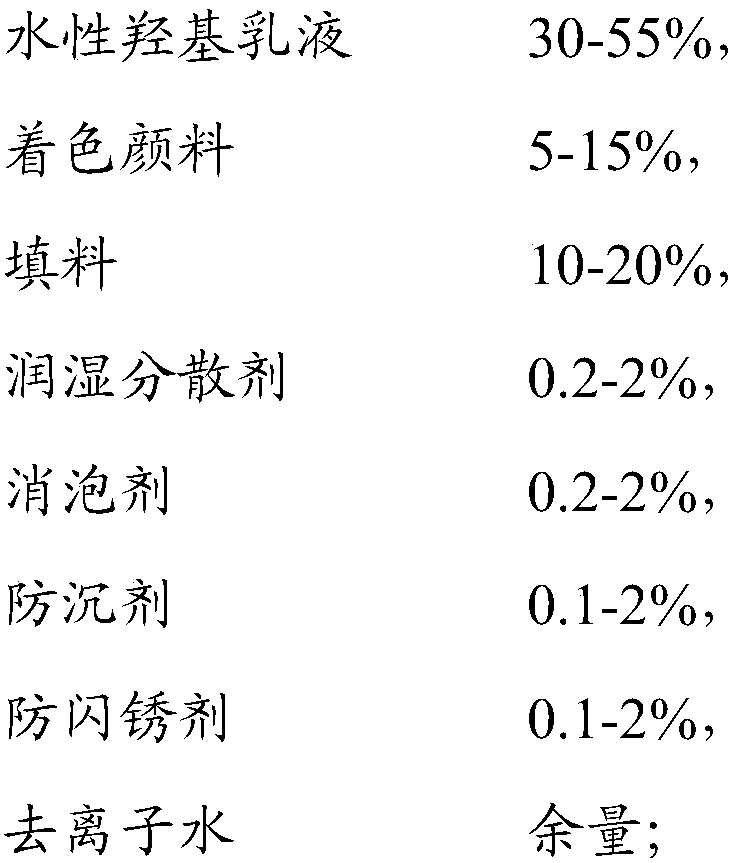

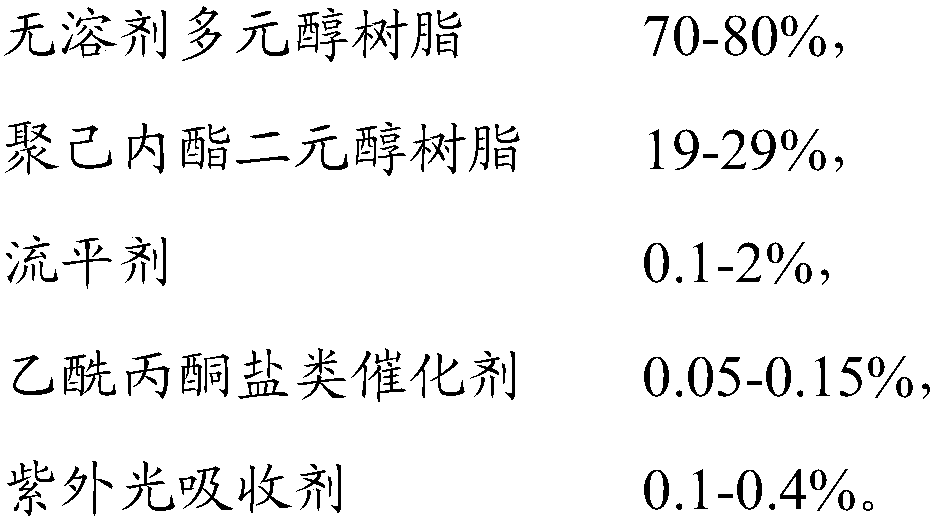

[0065] Table 2 Comp...

Embodiment 2

[0081] Preparation of coating system T-2

[0082] 2.1 Preparation of water-based anti-corrosion primer:

[0083] Table 5 Component A1 formula table

[0084]

[0085] Refer to the ratio in Table 5 to prepare component A1, add environment-friendly anti-corrosion pigments, fillers, wetting and dispersing agents and part of deionized water into the mixing container and mix evenly, and grind and disperse to a fineness of ≤30 μm to obtain a water-based pre-dispersion slurry; add the water-based predispersed slurry to the water-based epoxy emulsion, use a high-speed disperser to stir at a speed of 600r / min for 15min, then add defoamer, anti-settling agent and anti-flash rust agent in turn, use a high-speed disperser to 100r / min After stirring at a speed of 10 min, add the remaining deionized water, use a high-speed disperser to continue stirring at a speed of 300 r / min for 15 min, and filter with a 200-mesh silk screen to obtain component A1;

[0086] Table 6 Component B1 formula ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com