Thermal field for improving growth of zone-melting silicon and single crystal silicon

A technology of single crystal silicon and zone melting silicon, which is applied in the direction of single crystal growth, crystal growth, self-zone melting method, etc., can solve the problem of high requirements on the surface smoothness and roundness of polycrystalline materials, and the effect is not very good And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Pulling 4-inch single crystal, the diameter of the polycrystalline material is 114-119, with a diameter difference of 5mm, and there are pits on the surface of the material.

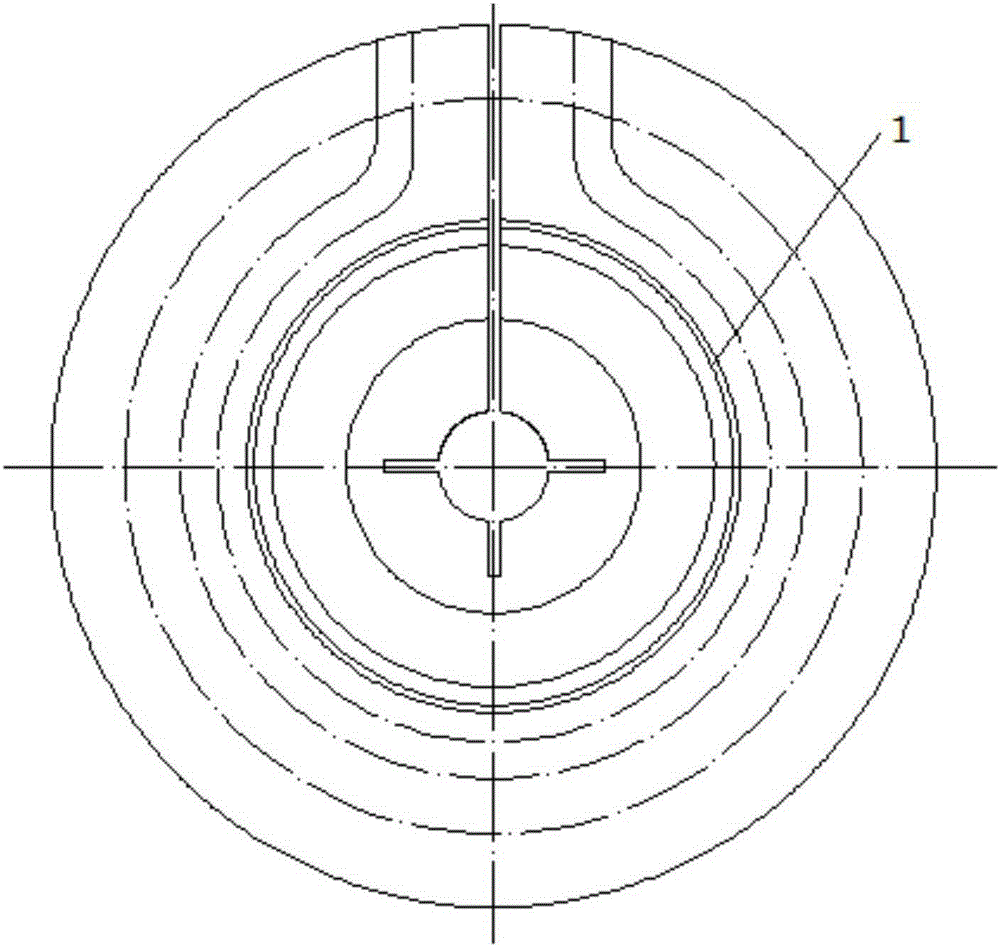

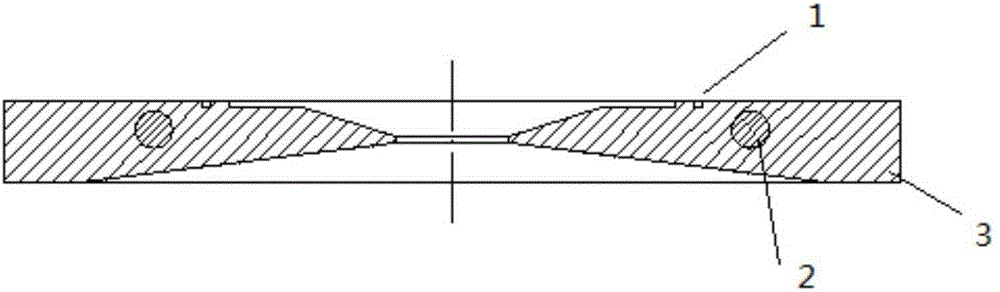

[0026] use as figure 1 and 2 In the thermal field described above, the single crystal expands to 50°, and the polycrystalline material begins to produce thorns; continue to expand normally, and the material is turned 90 degrees (upward rotation 0.4r / min), and the silicon thorns melt until the diameter of the single crystal is 70, and the upper Silicon thorns no longer appear in the material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com