Cleaning device used for clothes production

A cleaning device and clothing technology, applied in the field of clothing production, can solve the problems of discontinuity, general cleaning and decontamination ability, low cleaning efficiency, etc., and achieve the effects of reducing labor, strong cleaning and decontamination ability, and fast stain removal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

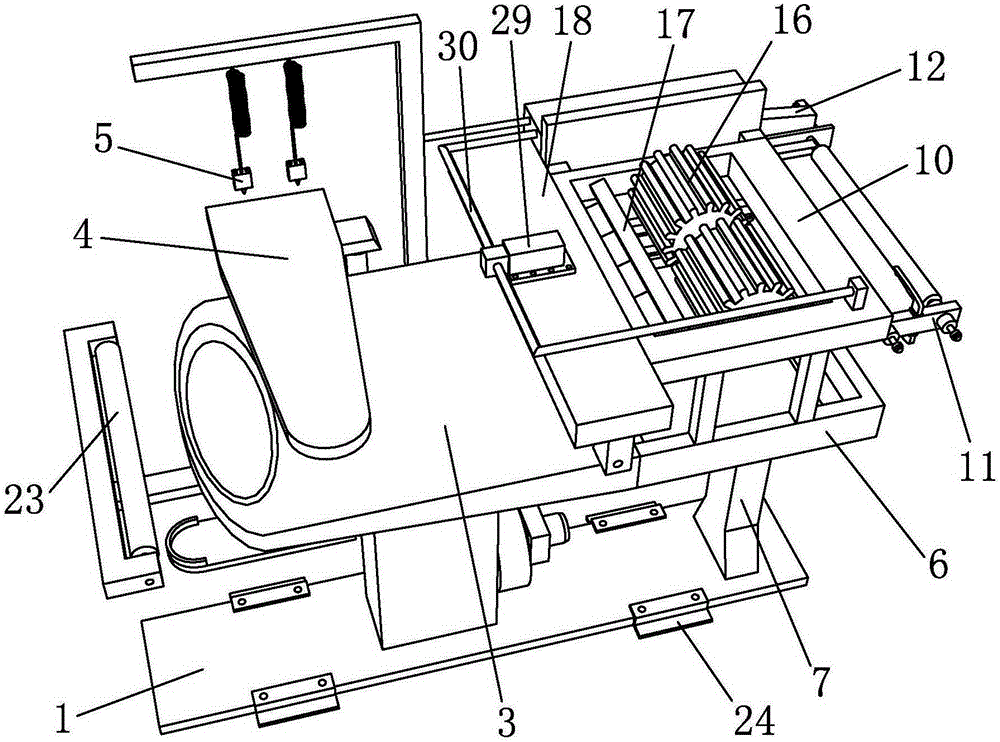

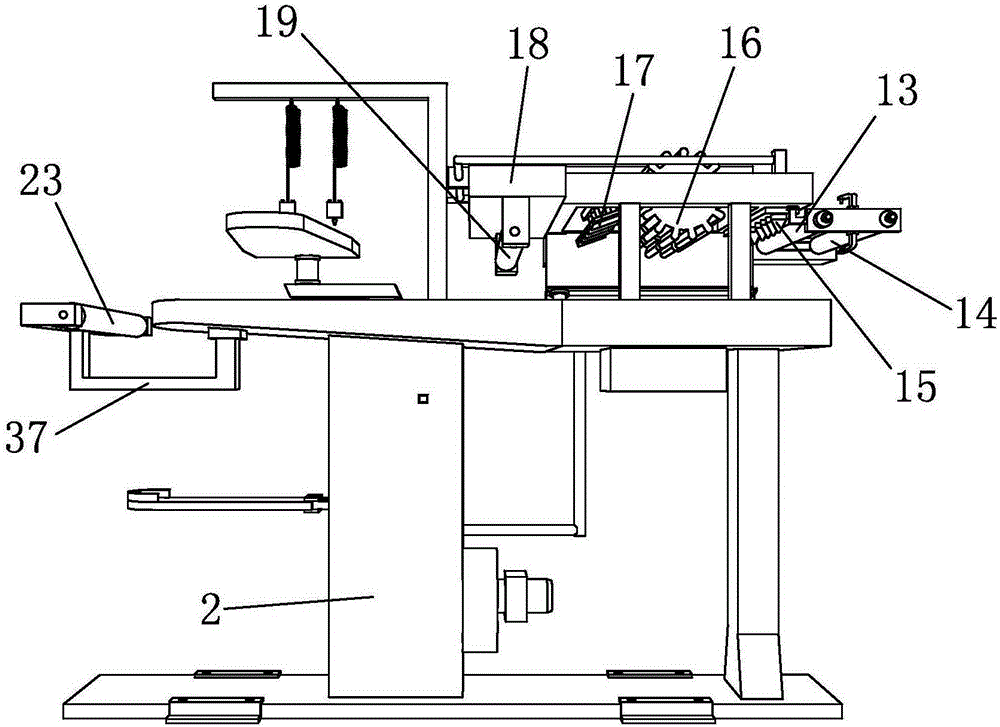

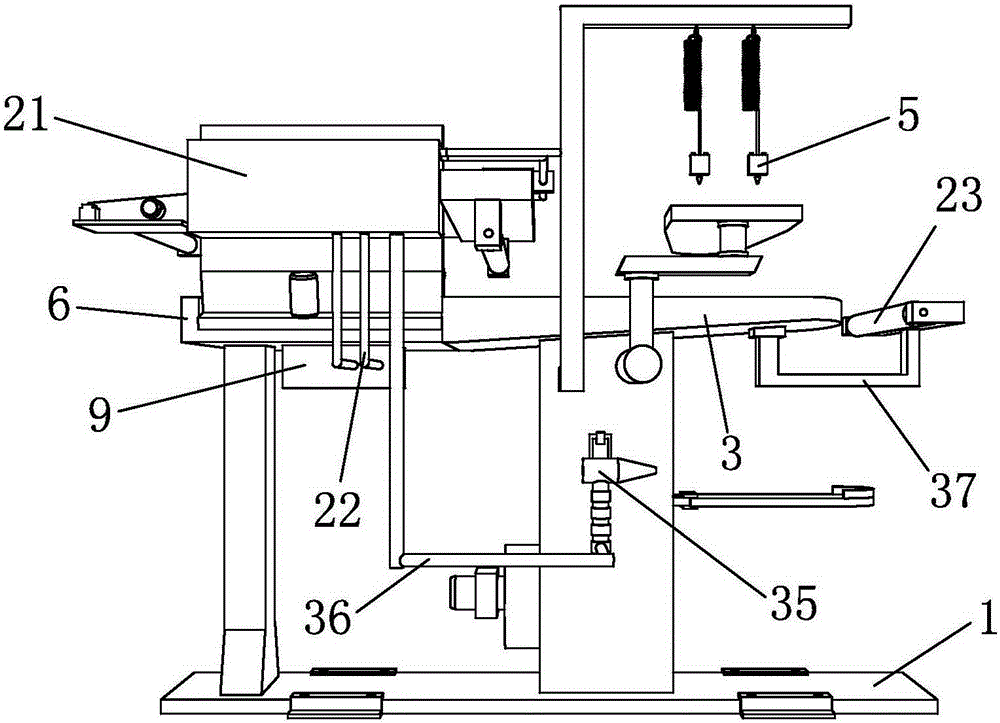

[0027] like Figure 1 to Figure 7 Shown is a cleaning device for garment production of the present invention, wherein, Figure 2 to Figure 4 view based on figure 1 The set direction prevails, and the left and right sides are also based on the figure 1 direction prevails. The invention includes a base 1, the base 1 is made of cast steel, and the carbon content in the casting process is 0.2% to 0.5%, and the obtained base 1 has high strength, high hardness, certain plasticity and toughness, and low cost , as the base 1 plays a supporting role for the whole device. The base 1 is provided with at least four metal fixing pieces 24 , and the metal fixing pieces 24 are connected to the base 1 by screws to improve the firmness and stability of the base 1 . The base 1 is provided with a body 2, the body 2 is provided with a cleaning table 3, and the body 2 is provided with an ironing table 4, which can be rotated on the body. When cleaning and decontaminating the fabric, the ironin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com