Integral type hard alloy pulsed nozzle and producing technology thereof

A pulse nozzle, cemented carbide technology, applied in construction and other directions, can solve the problems of non-wearability, splitting and falling off, and weak structure of steel parts, and achieve the effects of strong corrosion resistance, simple steps, and improved work production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

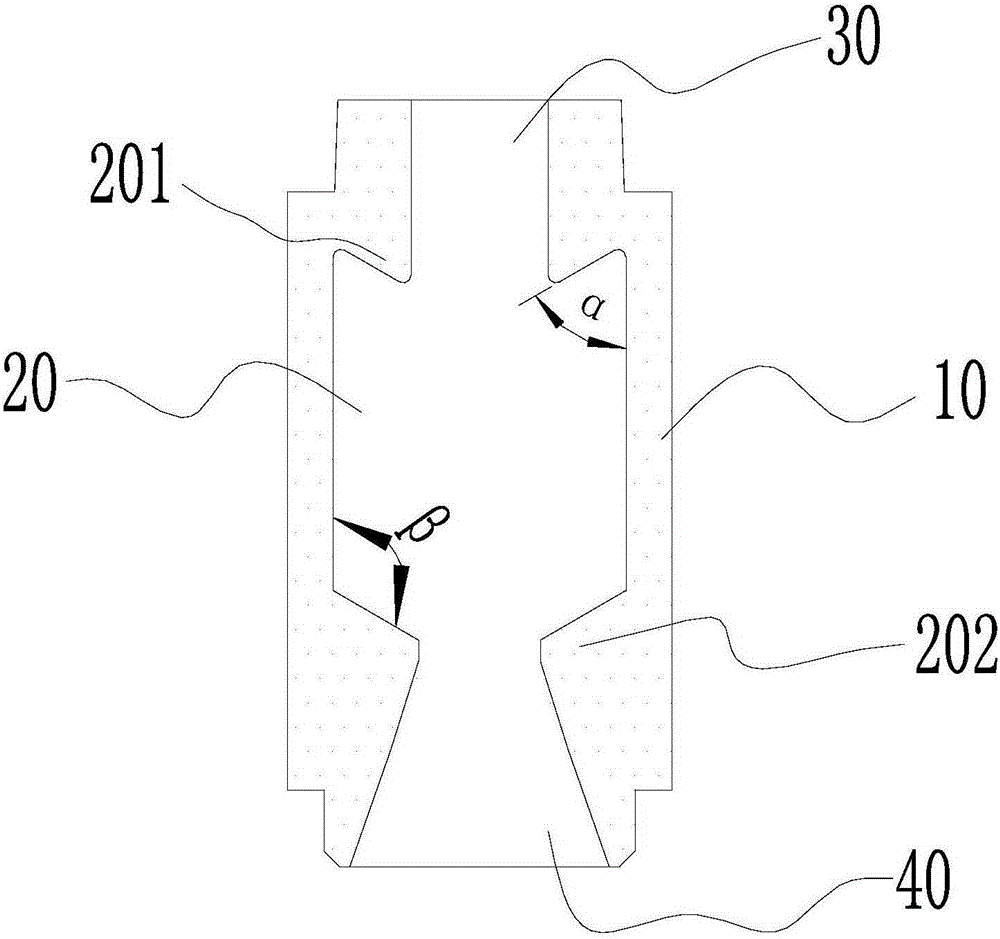

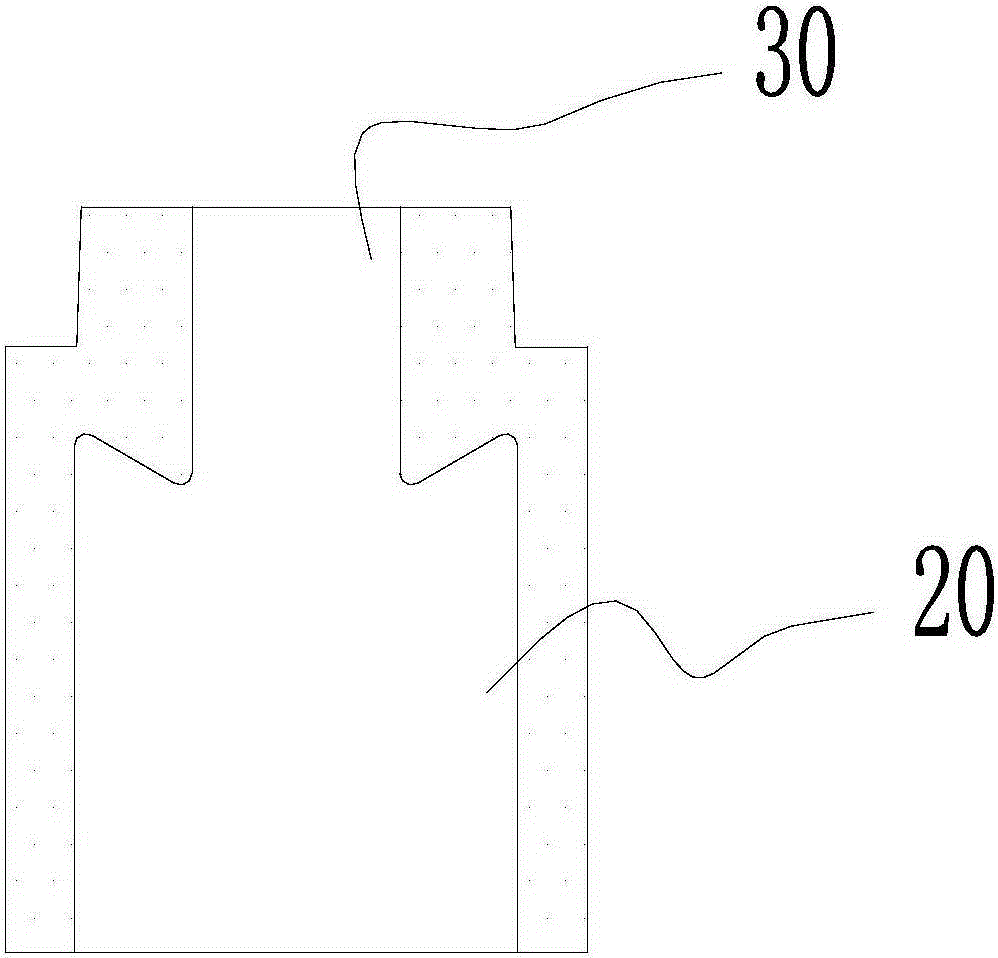

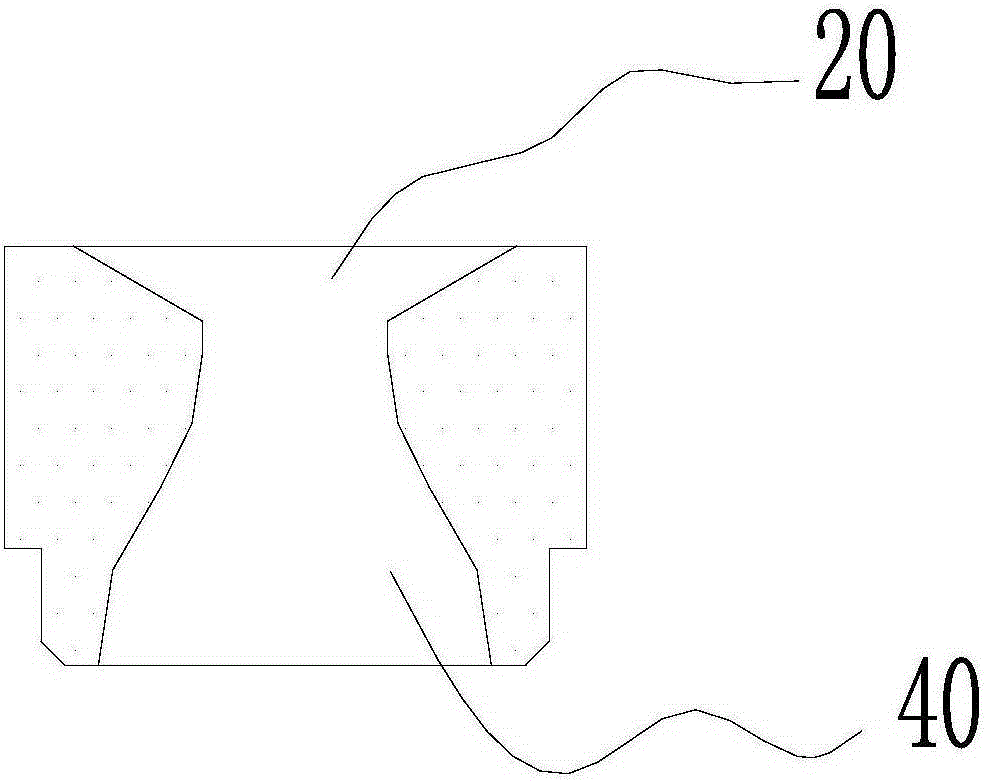

[0037] A one-piece carbide pulse nozzle, such as figure 1 As shown, the pulse nozzle main body 10 is included, the pulse nozzle main body 10 is a cylindrical structure, the pulse nozzle main body 10 is provided with a conical inner resonant cavity 20, the top of the inner resonant cavity 20 is provided with a nozzle outlet 30, and the inner resonant cavity The bottom of 20 is provided with diversion channel 40, inner resonant cavity 20, nozzle outlet 30, and diversion channel 40 form a hollow cavity with two large ends and a small middle, and an upper collision surface 201 is provided at the junction of inner resonant cavity 20 and nozzle outlet 30 , A lower impact surface 202 is provided at the joint between the inner resonant cavity 20 and the guide channel 40 .

[0038] The appearance shape and internal cavity structure of the pulse nozzle are relatively complex, and it is extremely difficult to produce a whole carbide pulse nozzle. In the present invention, at first will ...

Embodiment 2

[0040] The difference between this embodiment and Embodiment 1 is that the angle α between the upper impact surface and the wall of the inner resonant cavity is 60°, the angle β between the lower impact surface and the wall of the inner resonant cavity is 120°, and the upper impact surface Both the impact surface and the lower impact surface are conical structures.

Embodiment 3

[0042] The difference between this embodiment and Embodiment 1 and Embodiment 2 is that the diversion channels are conical, curved, streamlined, elliptical, arc-shaped, double-arc-shaped, and equal-speed shaped. one of the structures.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com