Unit plant coordination control method and system

A unit unit, coordinated control technology, applied in the field of electric power, can solve the problems of large fluctuations in operating parameters, and achieve the effects of reducing fluctuations, improving control accuracy, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

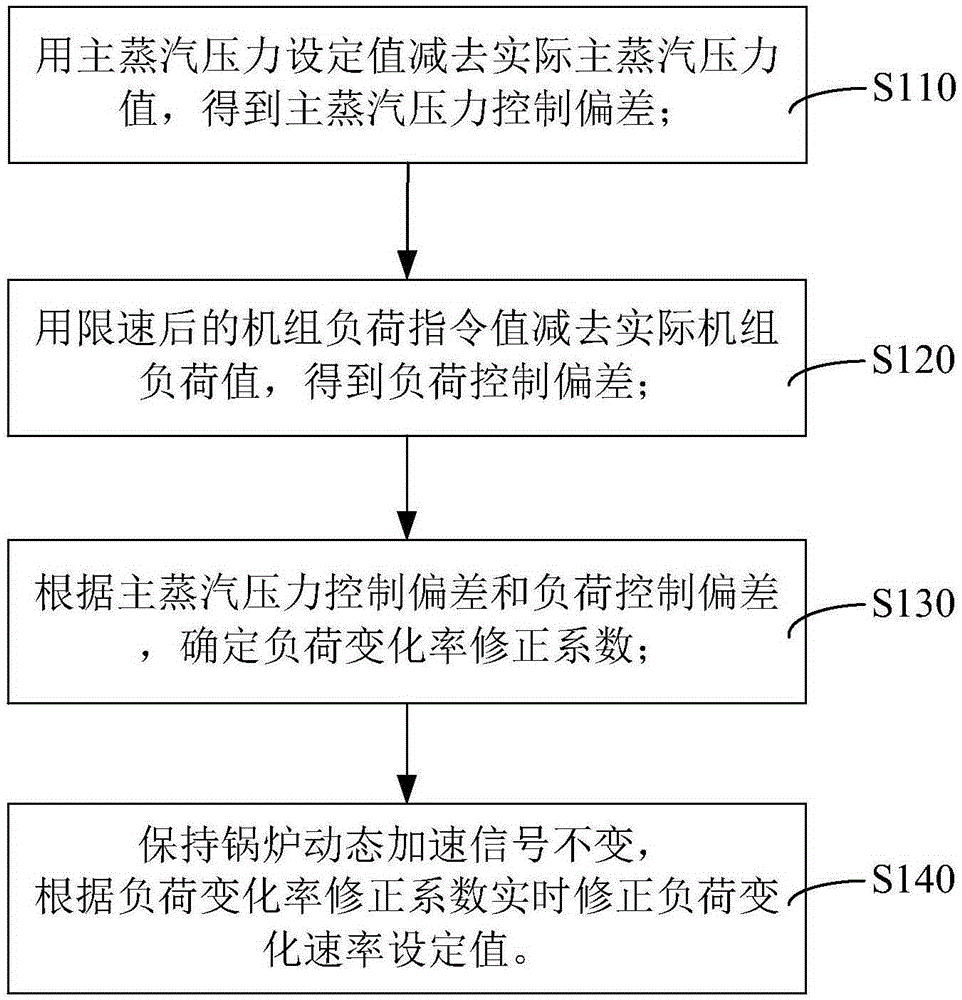

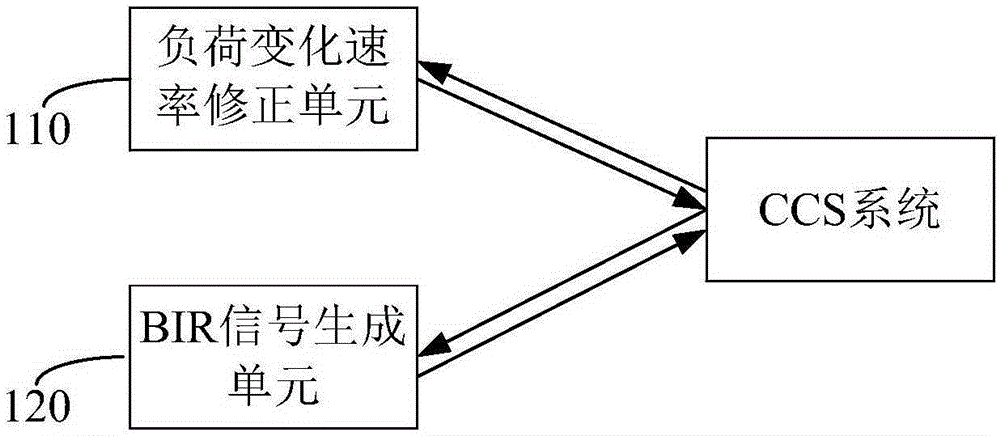

[0104] In addition, the present invention also provides a coordinated control system for unit units, figure 2 It is a schematic diagram of the system structure of Embodiment 1 of the unit unit coordinated control system of the present invention; figure 2 As shown, Embodiment 1 of the coordinated control system of unit units includes a load change rate correction unit 110 and a BIR signal generation unit 120 connected to the CCS system;

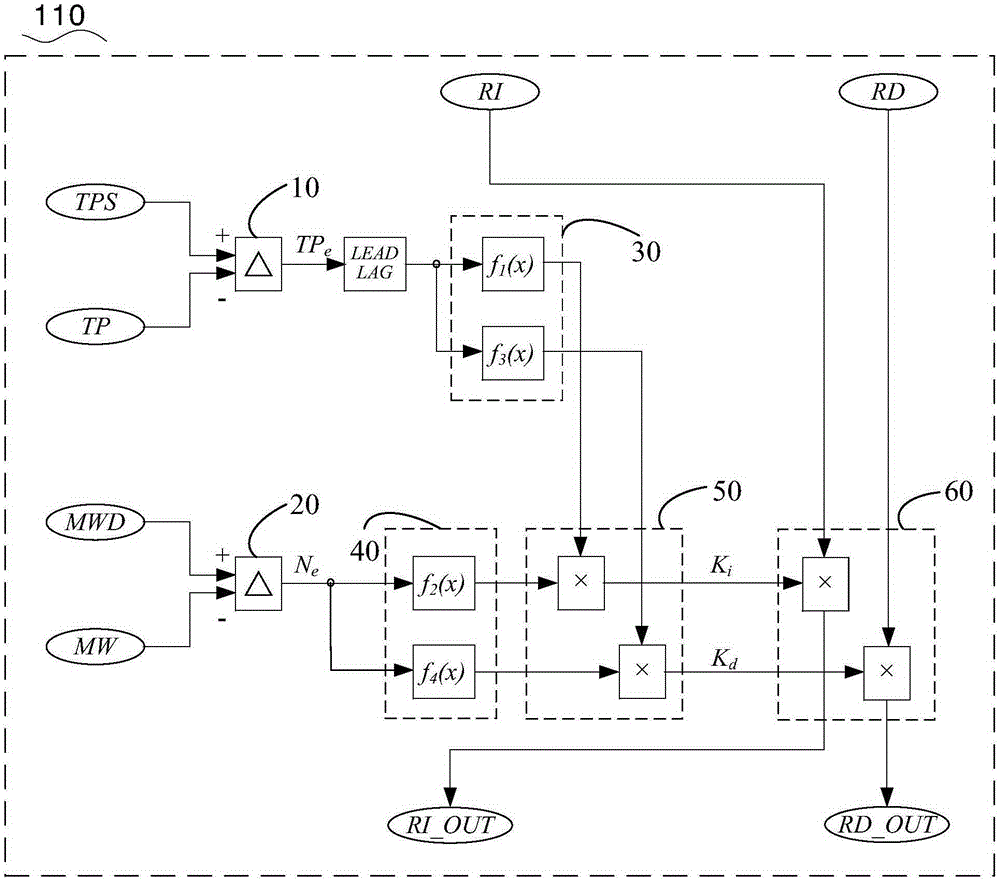

[0105] The load change rate correction unit 110 is used to process the set value of the main steam pressure and the actual main steam pressure value to obtain the control deviation of the main steam pressure; and process the unit load command value after the speed limit and the actual unit load value, Obtain the load control deviation; and use it to determine the load change rate correction coefficient according to the main steam pressure control deviation and the load control deviation; and to correct the load change rate setting value in r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com