Double-layer parallel flow condenser for integrated passenger car air conditioner

An integrated condenser technology, applied in the direction of evaporator/condenser, refrigerator, refrigeration components, etc., can solve the problems that the air intake area cannot be greatly changed, and the length direction of the front windward condenser cannot be lengthened, etc., to achieve Filling the gap in the market, the effect of small structure size and good pressure resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

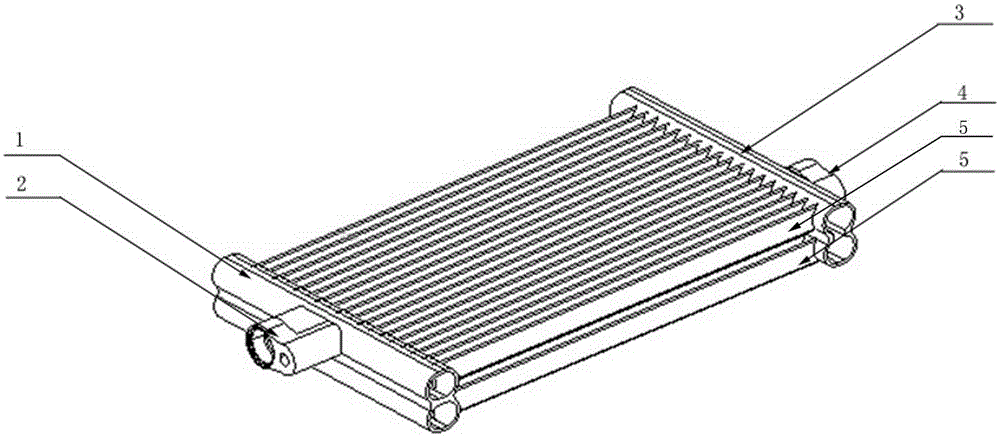

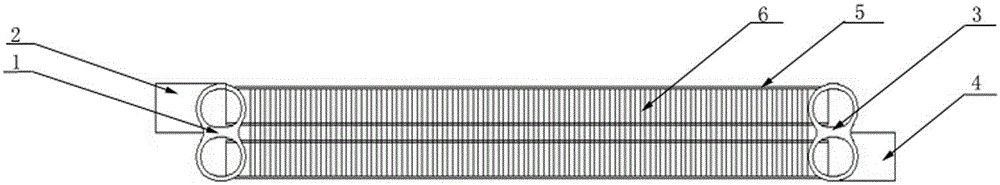

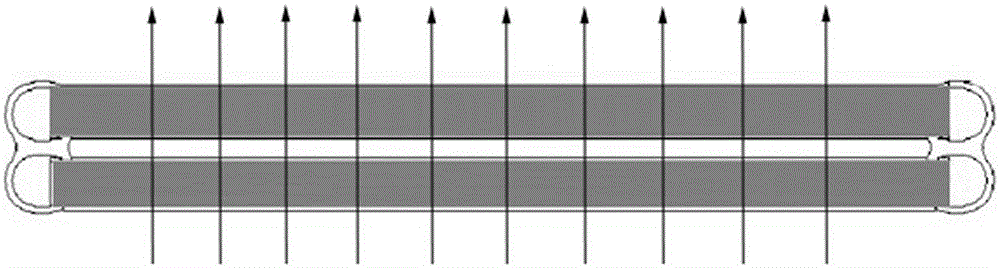

[0016] A double-layer parallel-flow condenser for an integrated passenger car air conditioner, such as figure 1 As shown, it includes a double-layer heat transfer system. The double-layer heat transfer system consists of a double-layer parallel flow refrigerant left header 1, a refrigerant inlet 2 installed on the upper tube of the double-layer parallel flow refrigerant left header 1, and a double-layer parallel flow refrigerant left header 1. Laminar parallel flow refrigerant right header 3, refrigerant outlet 4 installed on the lower tube of double layer parallel flow refrigerant right header 3, connecting double layer parallel flow refrigerant left header 1 and double layer parallel flow refrigerant right The header 3 consists of two layers of horizontally arranged heat transfer flat tubes 5 and heat transfer fins 6 arranged on the heat transfer flat tubes 5. The double-layer parallel flow refrigerant passes through the upper tube and the lower tube of the left header 1. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com