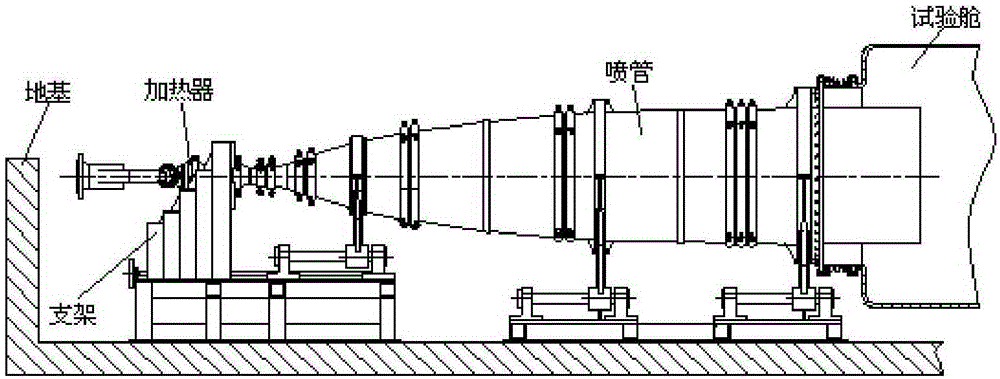

High-temperature jet pipe used for combustion gas flow wind tunnel

A gas flow and nozzle technology, which is applied in aerodynamic tests, machine/structural component testing, measuring devices, etc., can solve the problems of high nozzle loss rate and difficulty in replacement, and save maintenance and operating costs , reduce the difficulty, improve the effect of commonality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] 1. Nozzle design

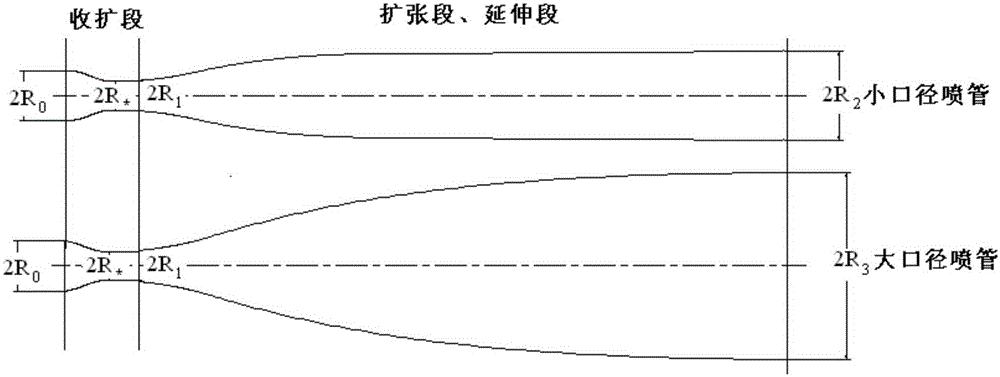

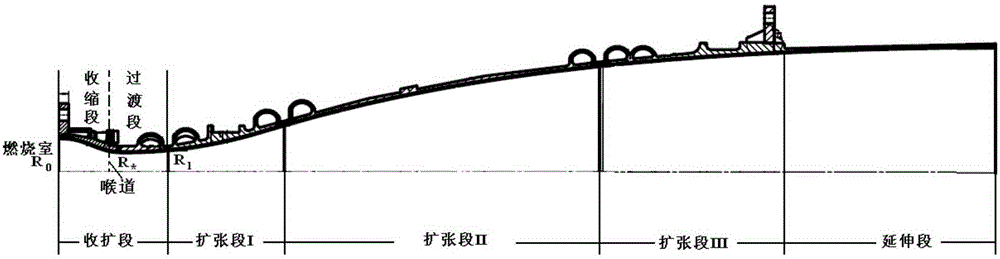

[0030] 1) The high-temperature nozzle used in the gas flow wind tunnel, including the expansion section and the expansion section, is selectively added to the extension section. The contraction-expansion section includes a contraction section and a transition section, such as figure 2 As shown, the constriction section of the nozzle is designed using the empirical formula of the Witoshinski curve, the transition section is an arc-shaped line, the radius is R, and the center of the circle is located on the longitudinal axis of the throat section.

[0031] see image 3 , the expansion section includes a first expansion section (expansion section I), a second expansion section (expansion section II, III); the profile line of the first expansion section is divided into a circular arc segment and a straight line segment, and the circular arc segment and the transition section For the same arc, the radius is also R, satisfying the relation R≥8R * , R *...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com