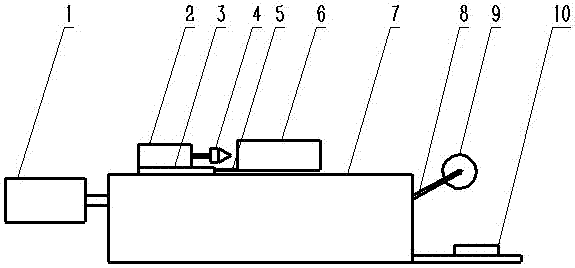

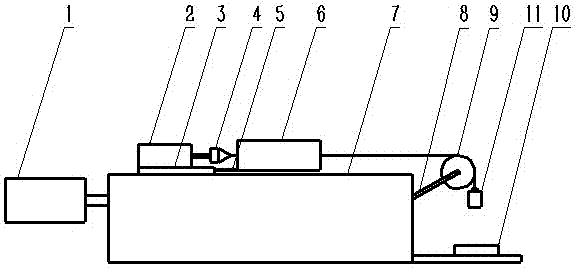

A Multifunctional Fiber Torsional Fatigue Performance Tester

A torsional fatigue, tester technology, applied in the direction of testing the strength of materials using applied repetitive force/pulsation force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

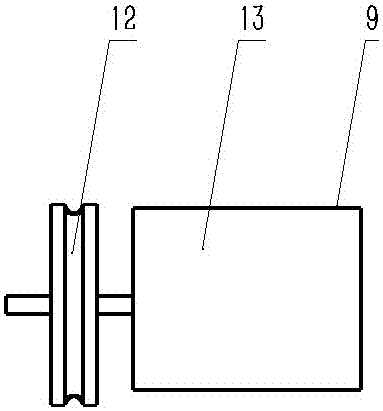

specific Embodiment 1

[0019]Take a cotton fiber with a length of 150mm, fix one end of it with a fiber holder, and the other end goes around the wheel and applies a 10g weight as tension, then the fiber holding tension at this time is 10cN. Through the control system, turn on the ambient atmosphere generator, adjust the temperature generator, and set the temperature to 50 degrees Celsius, so that the fiber under test is at this temperature, ready for the experiment. Turn on the switch of the torsion motor, adjust the rotation speed to 500r / min, set the motor to take the position angle of the fiber at rest as 0 degrees, first rotate 100 times forward and then reverse 100 times, and perform cyclical and alternating motions so that the fiber can be tested for torsional fatigue performance . During the torsional movement, due to the reduction of the length of the fiber, the rotation angle of the wheel is accepted by the pulse signal sent by the encoder, and then the fiber length tester sends the data t...

specific Embodiment 2

[0020] Take a cotton fiber with a length of 150mm, fix one end of it with a fiber holder, and the other end goes around the wheel and applies a 10g weight as tension, then the fiber holding tension at this time is 10cN. Through the control system, turn on the ambient atmosphere generator, adjust the humidity generator, and set the humidity to 70%, so that the fiber under test is at this humidity, ready for the experiment. Turn on the switch of the torsion motor, adjust the rotation speed to 500r / min, set the motor to take the position angle of the fiber at rest as 0 degrees, first rotate 100 times forward and then reverse 100 times, and perform cyclical and alternating motions so that the fiber can be tested for torsional fatigue performance . During the torsional movement, due to the reduction of the length of the fiber, the rotation angle of the wheel is accepted by the pulse signal sent by the encoder, and then the fiber length tester sends the data to the PC, which can dis...

specific Embodiment 3

[0021] Take a cotton fiber with a length of 150mm, fix one end of it with a fiber holder, and the other end goes around the wheel and applies a 10g weight as tension, then the fiber holding tension at this time is 10cN. Through the control system, turn on the ambient atmosphere generator, turn on the radiation generator, apply ultraviolet light, make the fiber under test under the radiant light, and prepare for the experiment. Turn on the switch of the torsion motor, adjust the rotation speed to 500r / min, set the motor to take the position angle of the fiber at rest as 0 degrees, first rotate 100 times forward and then reverse 100 times, and perform cyclical and alternating motions so that the fiber can be tested for torsional fatigue performance . During the torsional movement, due to the reduction of the length of the fiber, the rotation angle of the wheel is accepted by the pulse signal sent by the encoder, and then the fiber length tester sends the data to the PC, which ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com