Method for optimizing control system based on model system

A technology for optimizing control and control system, applied in general control system, program control, comprehensive factory control, etc., can solve the problems of complex identification algorithm, unable to ensure optimization results, difficult to popularize and so on, to achieve the steps and algorithms are intuitive and simple, easy to use Grasp and promote the effect that the conditions of use and implementation are easy to meet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

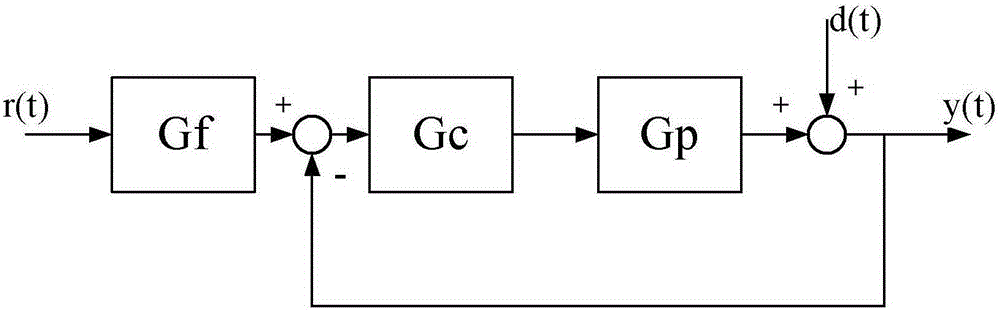

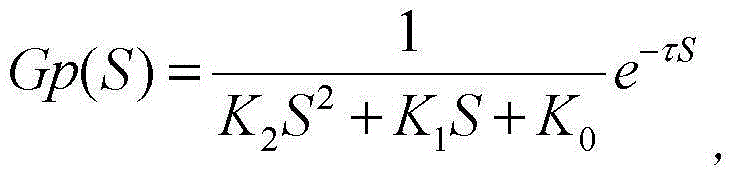

[0035] According to an embodiment of the present invention, the control system includes a filter Gf, a controller Gc, and a controlled object Gp, wherein the mathematical model specifying the controlled object Gp is:

[0036] G p ( S ) = 1 K 2 S 2 + K 1 S + K 0 e - τ S ,

[0037] (K 2 ≥0;K 1 >0;K 0 ≥0;τ>0)

[0038] This model basically covers the common first-order (K2=0), second-order, integral (K0=0), non-integral and time-delay (τ>0) objects that account for the majority of industrial processes, where , S is the Laplace op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com