Metal mesh based touch screen capable of sensing touch position and pressure

A metal grid and touch-sensitive technology, which is applied in the input/output process of data processing, instruments, electrical digital data processing, etc., can solve the problem of complex structure and process, high production cost, and the inability to accurately measure the vertical position information of the touch, etc. Problems, to achieve the effect of light and thin, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

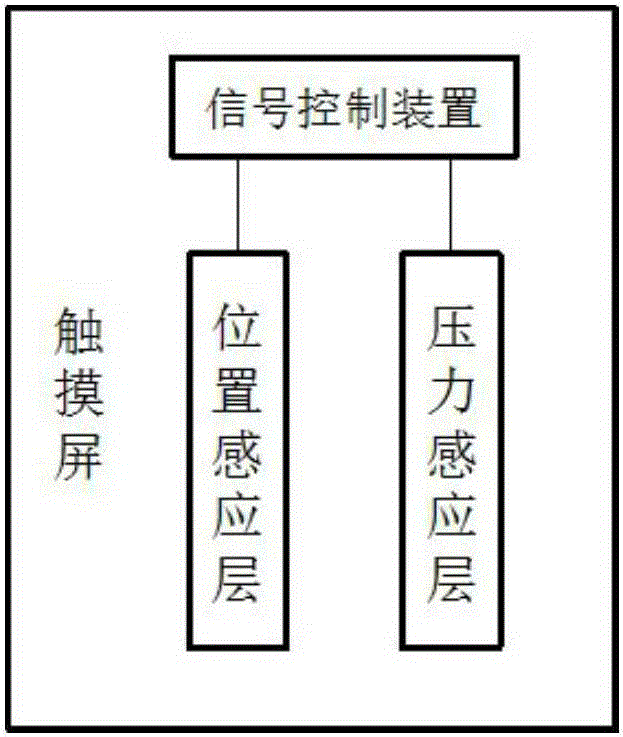

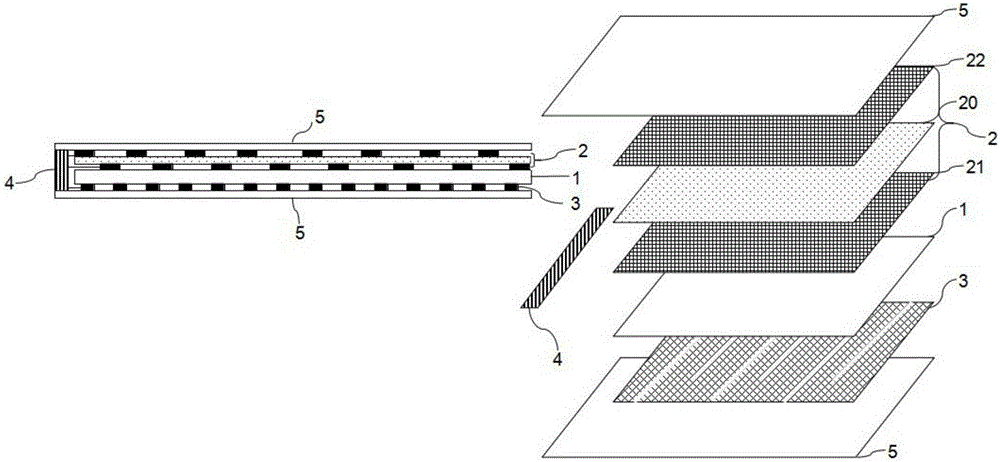

[0029] A touch screen based on a metal grid that can sense touch position and pressure, such as figure 1 , figure 2 , Figure 4 shown, including:

[0030] Transparent substrate 1;

[0031] The first metal grid layer 2, the first metal grid layer is a position sensing layer, by measuring the change of its capacitance, to sense the plane position information of the touch;

[0032] The second metal grid layer 3, the second metal grid layer is a pressure sensing layer, by measuring the change of its resistance, to sense the vertical pressure information of the touch;

[0033] Signal control device 4, the signal control device is connected with the first metal grid layer 2 and the second metal grid layer 3, used to receive the electrical signals of the two metal grid layers, and analyze the plane position of the touch action and vertical pressure.

[0034] Wherein, the first metal grid layer 2 and the second metal grid layer 3 are respectively located on both sides of the tra...

Embodiment 2

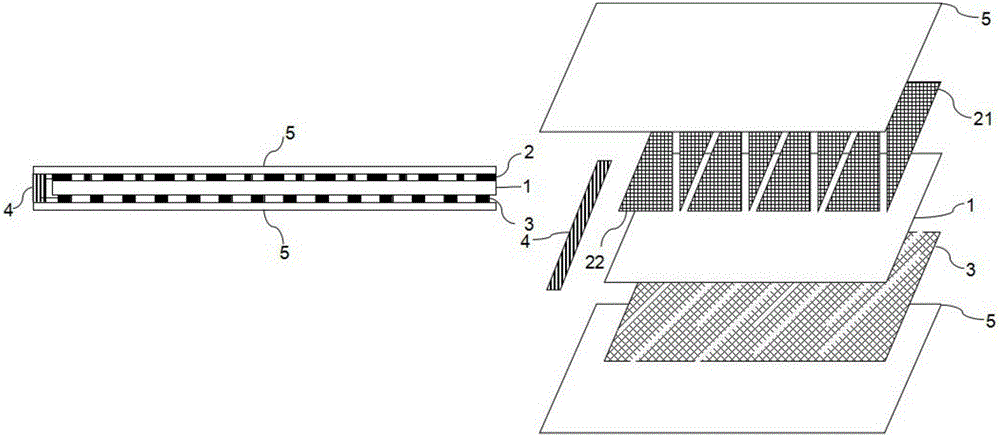

[0040] A touch screen based on a metal grid that can sense touch position and pressure, such as figure 1 , image 3 , Figure 4 shown, including:

[0041] Transparent substrate 1;

[0042] The first metal grid layer 1, the first metal grid layer 2 is a position sensing layer, by measuring the change of its capacitance, to sense the plane position information of the touch;

[0043] The second metal grid layer 3, the second metal grid layer 3 is a pressure sensing layer, by measuring the change of its resistance, to sense the vertical pressure information of the touch;

[0044] Signal control device 4, the signal control device 4 is connected with the first metal grid layer 2 and the second metal grid layer 3, used to receive the electrical signals of the two metal grid layers, and analyze the plane of the touch action position and vertical pressure.

[0045]Wherein, the first metal grid layer 2 and the second metal grid layer 3 are respectively located on both sides of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com