Efficient passivation contact crystalline silicon solar cell preparation method

A technology for solar cells and crystalline silicon, applied in the field of solar cells, can solve the problems of unfavorable mass production, high cost, complicated preparation process, etc., and achieve the effects of favorable cost, improved filling factor, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

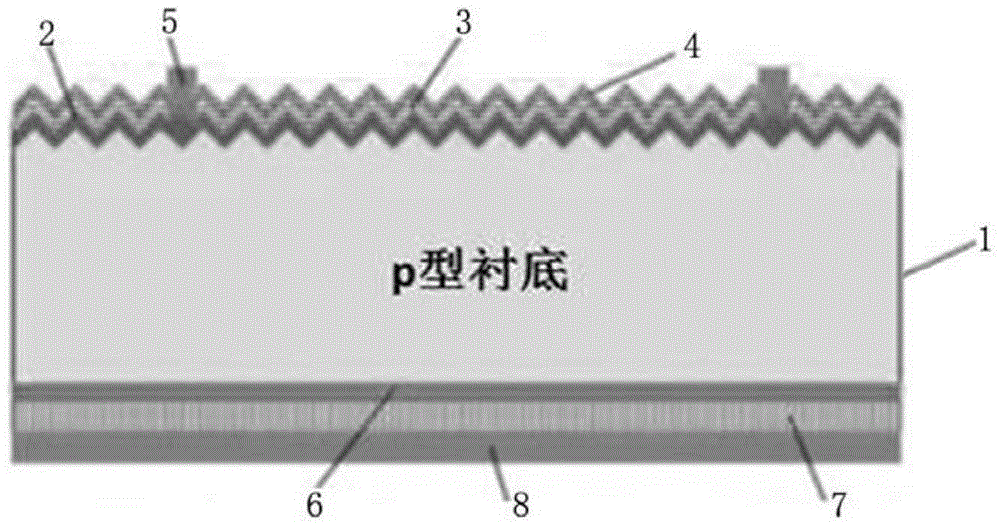

[0030] In order to enable those skilled in the art to better understand the solutions of the present invention, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

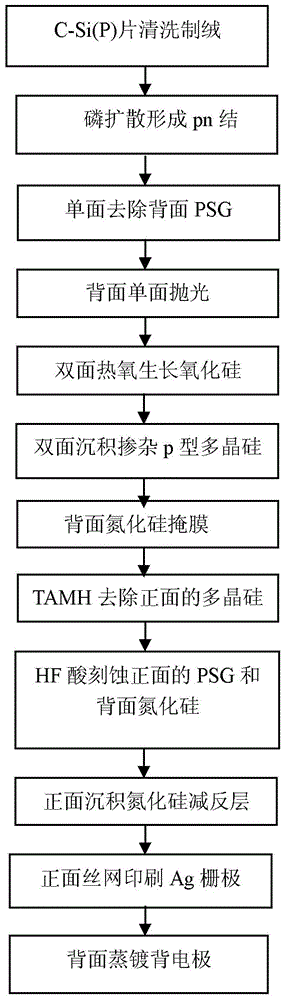

[0031] The preparation method of the highly efficient passivation contact crystalline silicon solar cell of the present invention comprises the following steps:

[0032] Taking P-type single crystal silicon as the silicon substrate as an example, the conventional texturing and diffusion process is carried out first. In the diffusion process, the P-type substrate uses group V elements, such as phosphorus (P), arsenic (As), N-type impurities such as bismuth (Bi), antimony (Sb), etc.; P of group III elements (including boron (B), aluminum (Al), gallium (Ga), indium (In), etc.) are used for N-type substrate diffusion Type impurities to form a P-N junction. In this embodiment, ph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap